Automatic die carrying die change system and method in unmanned state

A mold, automatic technology, used in motor vehicles, transportation and packaging, etc., can solve problems such as unreasonable structure, lack of elevators, high synchronization and resistance to lateral forces, and achieve the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0073] Below in conjunction with accompanying drawing, the present invention is further described:

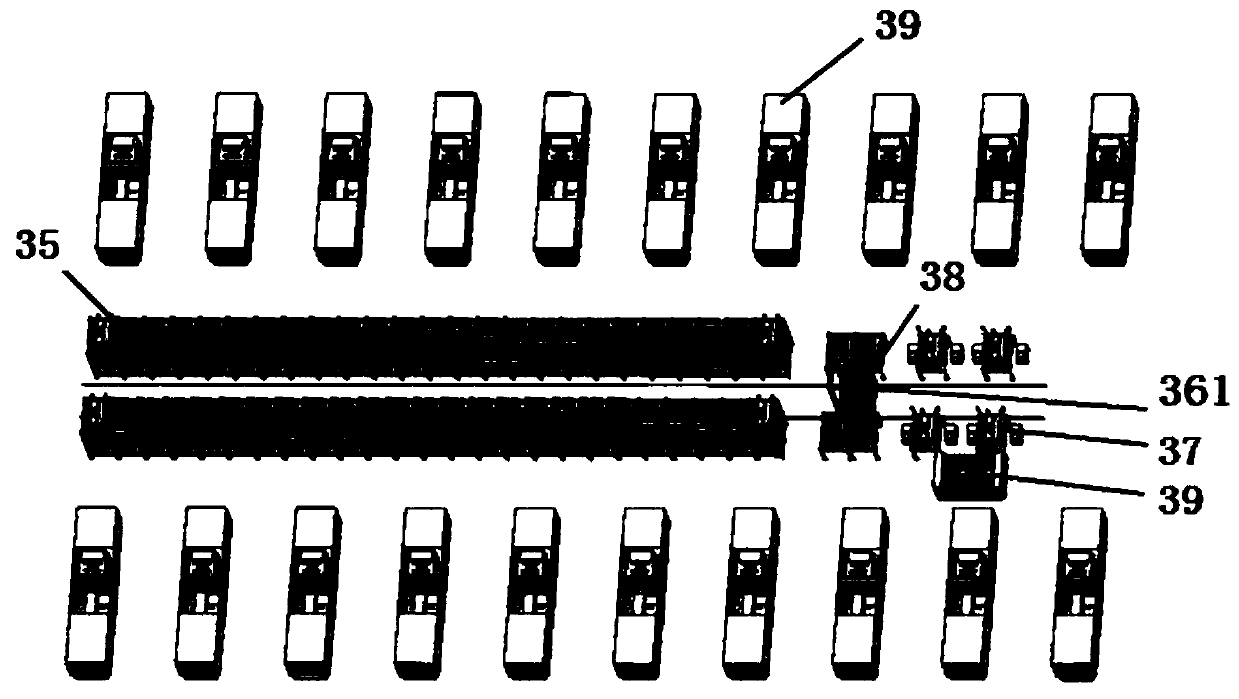

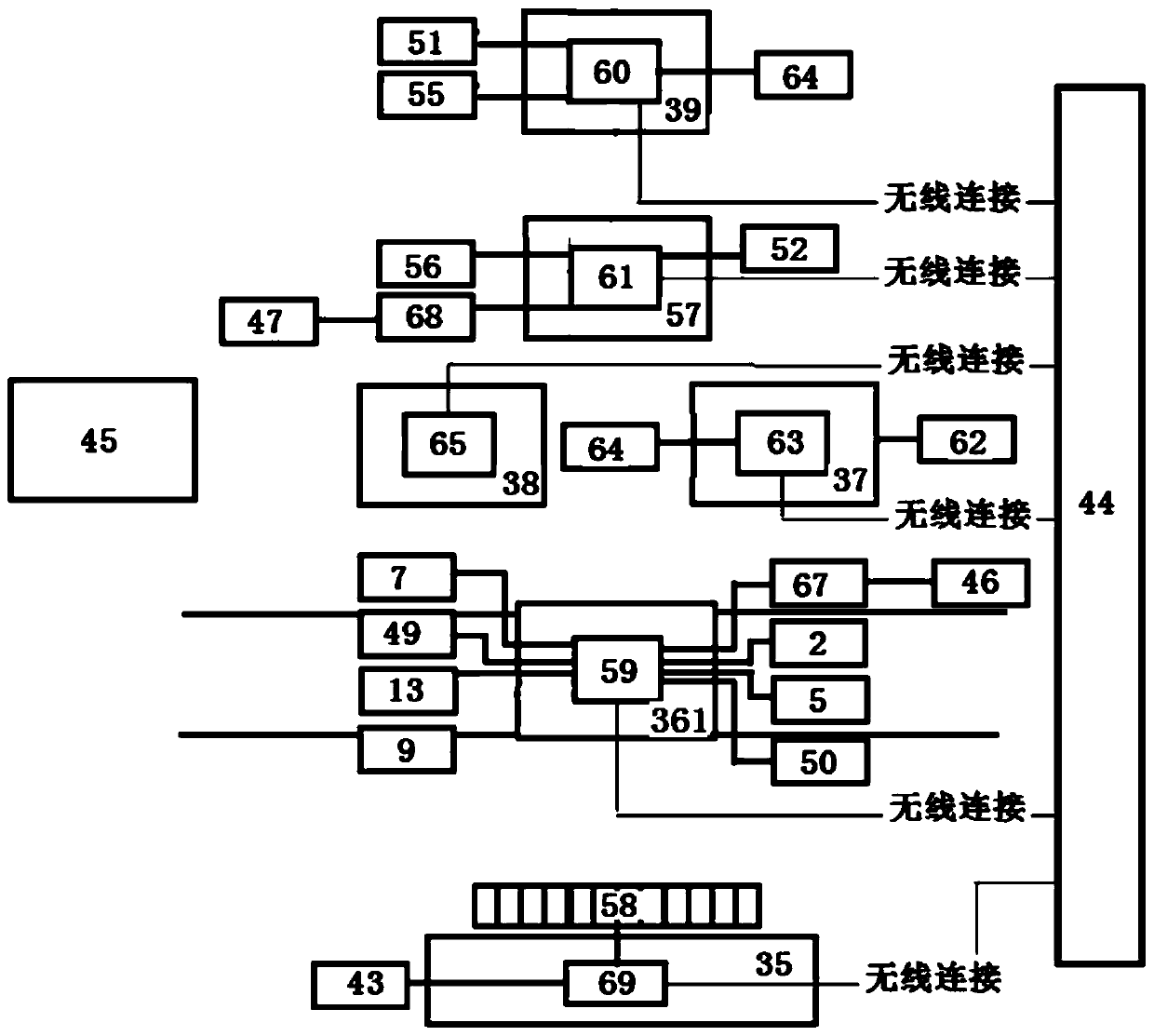

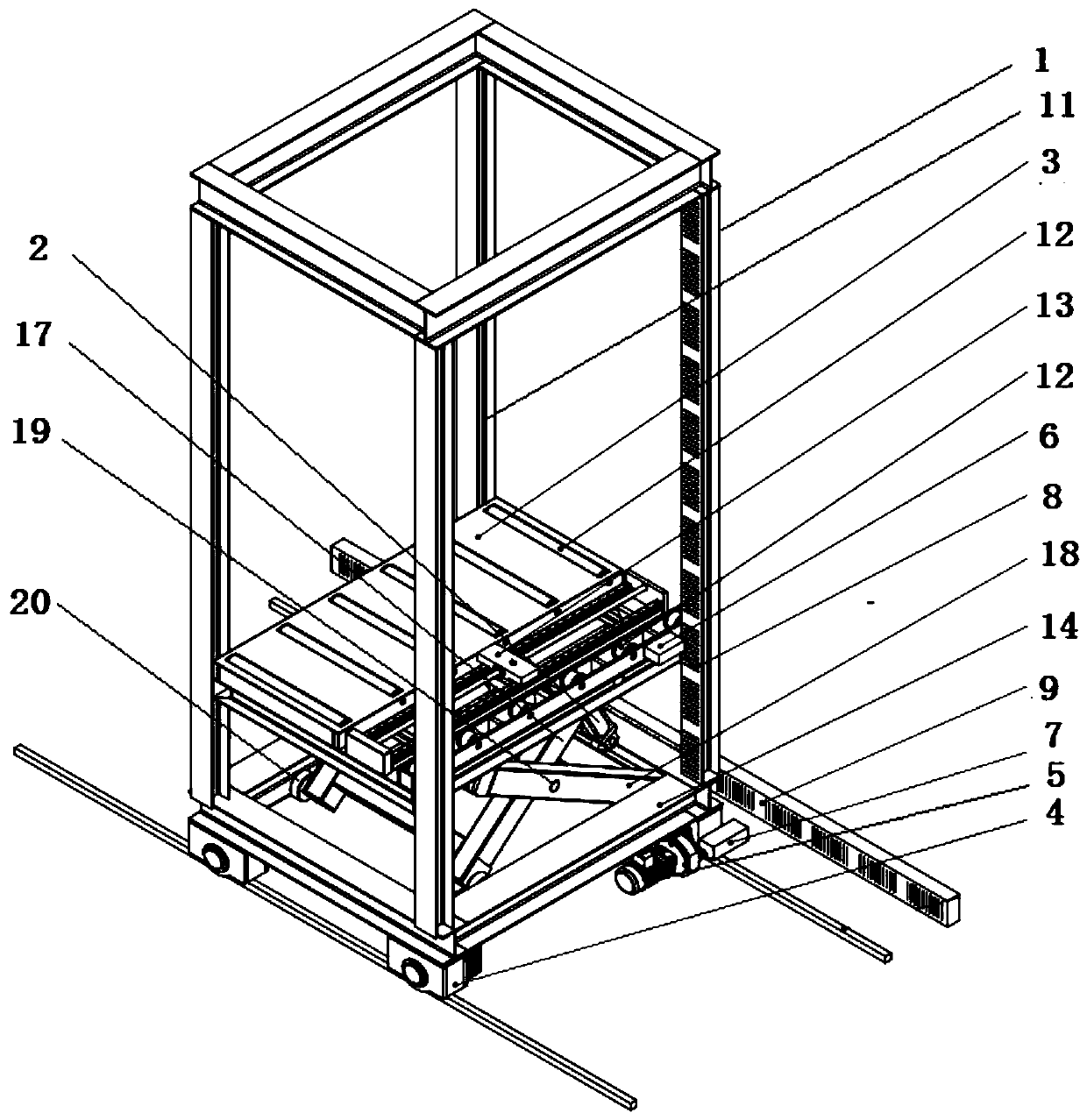

[0074] As shown in the accompanying drawings, an automatic mold transfer and mold change system in an unmanned state includes a mold library 35, a mold transport vehicle 361, a preheating station 37, a transition platform 38, a mold change trolley 57, an injection molding machine 39 and a control system. System 44 is characterized in that it also includes automatic charging station 45, first charging module 46, second charging module 47, RFID electronic tag 48, RFID card reader 49, wireless communication module 50, two-dimensional code 51, two-dimensional code identification Device 52, walking positioning code reader 53, unit position sensor 54, first wireless communication module 55, second wireless communication module 56, walking positioning code reading device 7, walking barcode 9, transition platform mold in-position switch 65, control chip 59 , transition platform control...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com