Butyl rubber solution and preparation method thereof

A butyl rubber and solution technology, applied in the rubber field, can solve the problems of low gel content, quality defects, difficult to prepare low primary structure content, etc., and achieve the effect of excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

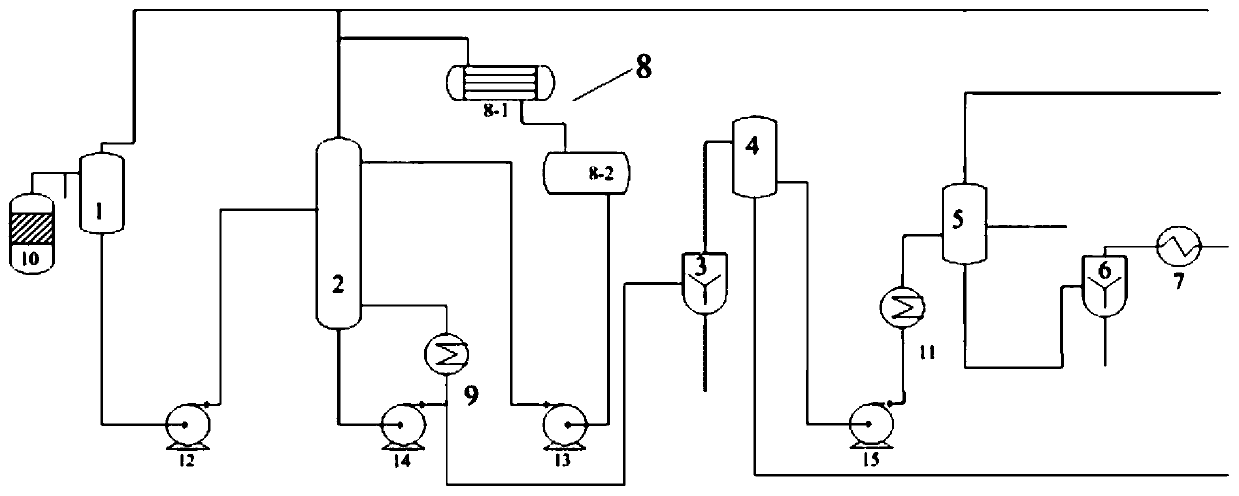

[0047] The invention provides a kind of preparation method of butyl rubber solution, it is characterized in that, comprises the following steps:

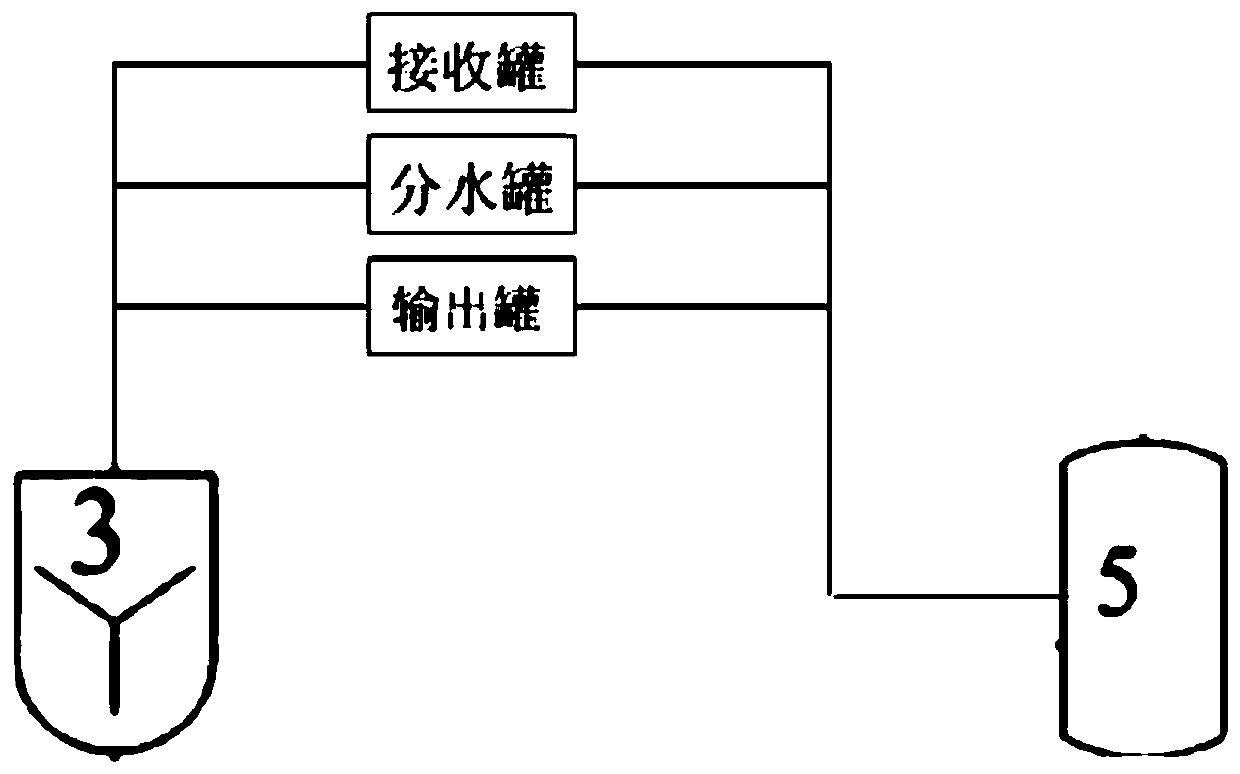

[0048] a) contacting the polymer slurry with a solvent and a catalyst deactivator in a flash tank to obtain glue A;

[0049] b) sending the glue solution A into a stripping tower, and contacting the solvent vapor in reverse in the stripping tower to obtain glue solution B;

[0050] c) performing a water addition treatment, a dehydration treatment, a concentration adjustment treatment, a second water addition treatment and a heat exchange treatment on the glue B in sequence to obtain a butyl rubber solution;

[0051] The catalyst kill is a catalyst kill of the residual catalyst in the polymer slurry.

[0052] In the present invention, the polymer slurry is first contacted with the solvent and the catalyst deactivator in the flash tank, and the catalyst in the polymer sludge is deactivated by using the catalyst deactivator, and after...

Embodiment 1

[0124] 1.1 Adoption figure 1 The preparation device carries out the preparation of butyl rubber solution, specifically as follows:

[0125] With methyl chloride as the medium, AlEtCl 2 and HCl as catalyst (AlEtCl 2 : The mass ratio of HCl is 18:1), and isobutylene and isoprene are monomers (the mass ratio of isobutylene:isoprene is 100:3). AlEtCl 2 Dissolve in methyl chloride to obtain a catalyst solution with a concentration of 0.3 wt% and a flow rate of 0.6 kg / h. The concentration of the mixed material obtained by mixing the monomer and methyl chloride is 30 wt%, and the flow rate is 10 kg / h. The polymerization reaction was carried out in the polymerization reactor 10 (the polymerization temperature was -95° C.), and the monomer conversion rate was 90%.

[0126] The above-mentioned polymer slurry is sent to flash tank 1 (flow rate 10.6kg / h, temperature -93°C, pressure 2bar), and at the same time, hexane hot solvent and triethylene glycol deactivator are sent to flash ta...

Embodiment 2

[0137] Prepare the butyl rubber solution according to the preparation process of Example 1, the difference is that the catalyst deactivator added in the flash tank 1 is butanol, and the butanol content in the glue A is 500ppm; add the first high-speed mixer 3 The amount of water added is 4.0wt%, and water is added to the second mixer 6 until the water content of the glue is 0.6wt%. After the heat exchange treatment in the heat exchanger 7, the temperature of the glue is 45 ° C, and the final butyl rubber solution The concentration is 18.0wt%, the monomer content is 1.7ppm, the water content is 0.6wt%, and the temperature is 45°C.

[0138] According to the preparation process of Example 1, the obtained butyl rubber solution was used to prepare brominated butyl rubber.

[0139] The Mooney drop and primary structure content of the obtained bromobutyl rubber were tested according to the test method in Example 1. The results showed that the Mooney drop was 9.5%, the primary structu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com