Weak impregnated prepreg of carbon-containing nanotube and preparation method thereof

A technology of carbon nanotubes and nanotubes, which is applied in the field of weakly impregnated prepregs containing carbon nanotubes and its preparation, can solve the problems of low actual content between layers and the inability to flexibly control the content of carbon nanotubes, and achieve easy preparation and increase Content, the effect of increasing the volume fraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A weakly impregnated prepreg containing carbon nanotubes in this embodiment includes a fiber fabric and a resin film base, carbon nanotubes are distributed in the resin film base, the fiber fabric is covered on the resin film base, and the bottom of the fiber fabric is The surface part is impregnated with the resin film base. In this embodiment, one layer of resin film base is used, the thickness is 0.3mm, the thickness of fiber fabric is 0.2mm, and the thickness of partially impregnated is 0.05mm.

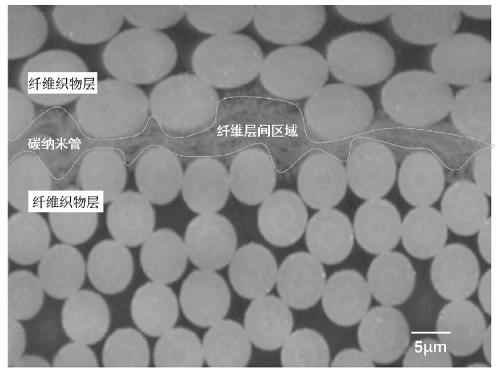

[0041] figure 1 It is a schematic diagram of the hindering effect of the fiber fabric on the interlayer of carbon nanotubes in the present invention. From figure 1 It can be seen that the dense fiber fabric has an obvious hindering effect on the interlayer carbon nanotubes, making a large number of carbon nanotubes stay in the interlayer region, thereby effectively increasing the interlayer carbon nanotube volume fraction.

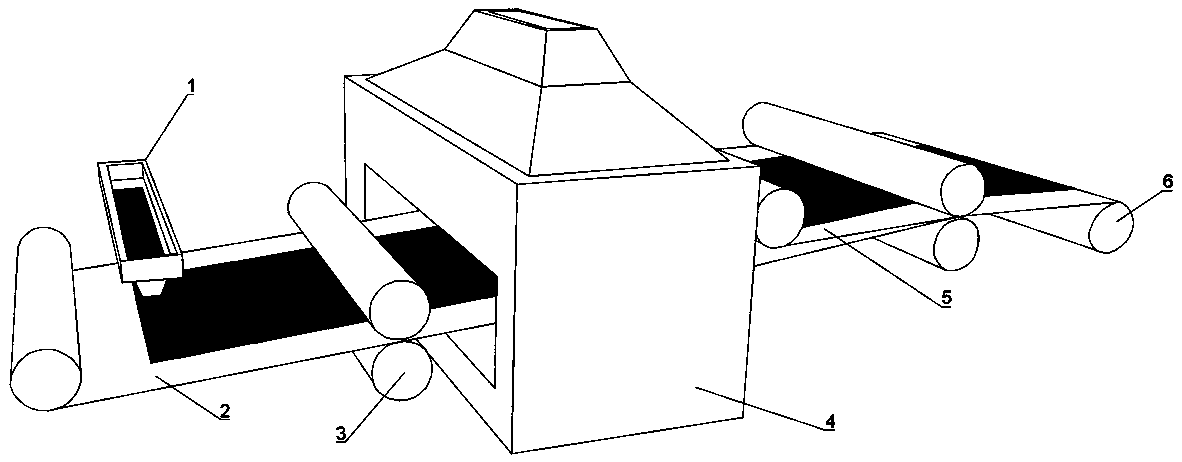

[0042] The schematic diagram of the weakly imp...

Embodiment 2

[0054] The weakly impregnated prepreg containing carbon nanotubes of the present embodiment is basically the same as that of Embodiment 1, the only difference being:

[0055] The number of layers of the used resin film base is 2, and the fiber fabric is a 1K carbon fiber orthogonal plain fabric with a thickness of 0.15 mm.

[0056] The preparation method of the weakly impregnated prepreg containing carbon nanotubes of this embodiment is basically the same as that of Example 1, the only difference being:

[0057] In step d), two resin films with the same size of 200mm×200mm are cut out, and stacked neatly in sequence, and then stacked with the 11K carbon fiber orthogonal plain weave fabric.

[0058] In step e), the pressure applied to the plate is 10kPa, and the holding time is 2 minutes.

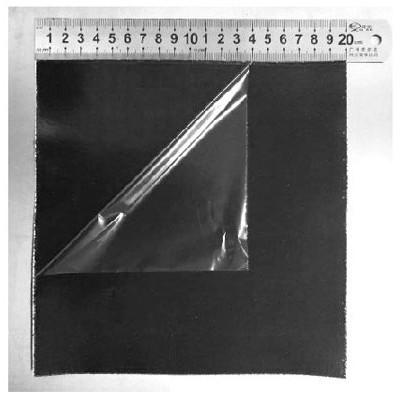

[0059] The weakly impregnated prepreg containing carbon nanotubes of the present embodiment, such as Figure 6 As shown, the surface of the weakly impregnated prepreg is flat, the thicknes...

Embodiment 3

[0061] The weakly impregnated prepreg containing carbon nanotubes of the present embodiment is basically the same as that of Embodiment 1, the only difference being:

[0062] The number of layers of the resin film substrate used is 3, and the fiber fabric is a 3K carbon fiber orthogonal plain fabric with a thickness of 0.2mm.

[0063] The partially impregnated thickness is 0.07mm.

[0064] The preparation method of the weakly impregnated prepreg containing carbon nanotubes of this embodiment is basically the same as that of Example 1, the only difference being:

[0065] In step d), three resin films with the same size of 200mm×200mm are cut out, and stacked neatly in sequence, and then stacked with 3K carbon fiber orthogonal plain weave fabric.

[0066] In step e), the pressure applied to the plate is 12kPa, and the holding time is 3 minutes.

[0067] The weakly impregnated prepreg containing carbon nanotubes of the present embodiment, such as Figure 7 As shown, the surfac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com