High-temperature-resistant and flame-retardant tetrafunctional epoxy resin with diazaphthone structure and preparation method of tetrafunctional epoxy resin

A phthalazinone and four-functionality technology, which is applied in the field of polymer science, can solve the problem of decreased heat resistance, lower glass transition temperature, and improvement of the mechanical properties and heat resistance of cured products of tetrafunctional epoxy resins Can not take into account other issues, to achieve the effect of high bending strength, high impact strength and heat resistance, good mechanical strength and flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

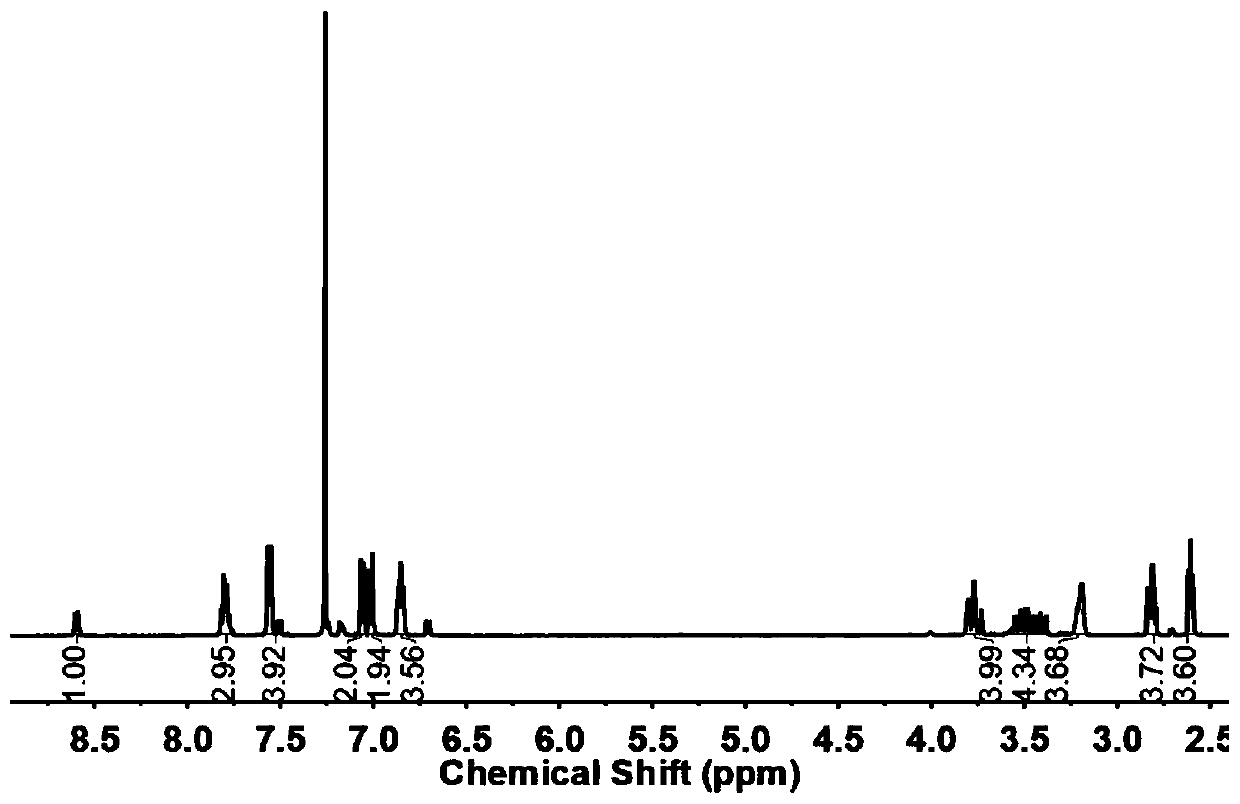

Method used

Image

Examples

Embodiment 1

[0035] Mix 1g TEPZ and 10g TGDDM resin, preheat at 110°C and stir mechanically until it becomes light yellow and transparent, then add 4.4g 4,4'-aminodiphenylmethane curing agent, when the mixed system becomes transparent again, put It was placed in a preheated vacuum oven for degassing for 45 minutes. Finally, inject the homogeneously mixed melt into the mold, and solidify in a blast oven according to the temperature program of 100°C / 2h, 130°C / 2h, 150°C / 2h, and 180°C / 2h.

Embodiment 2

[0037] Mix 2g of TEPZ and 10g of TGDDM resin, preheat at 110°C and mechanically stir until it becomes light yellow and transparent, then add 4.8g of 4,4'-aminodiphenyl ether curing agent, when the mixed system becomes transparent again, put It was placed in a preheated vacuum oven for degassing for 45 minutes. Finally, inject the homogeneously mixed melt into the mold, and solidify in a blast oven according to the temperature program of 120°C / 2h, 150°C / 2h, 180°C / 2h, 200°C / 1h.

Embodiment 3

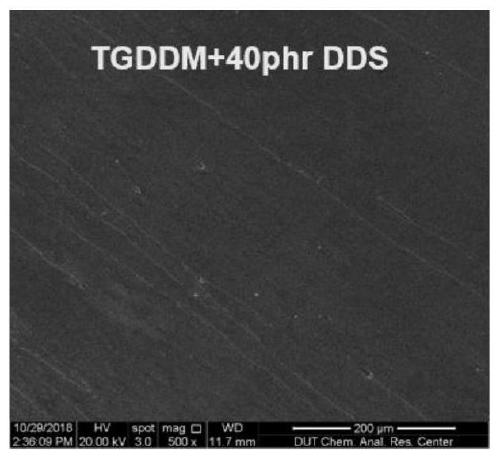

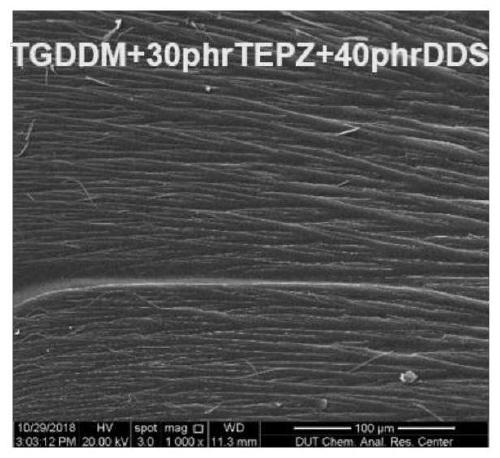

[0039] Mix 3g of TEPZ and 10g of TGDDM resin, preheat at 110°C and mechanically stir until it appears light yellow and transparent, then add 5.2g of 4,4'-aminodiphenyl sulfone curing agent, when the mixed system becomes transparent again, put It was placed in a preheated vacuum oven for degassing for 45 minutes. Finally, inject the homogeneously mixed melt into the mold, and solidify in a blast oven according to the temperature program of 130°C / 2h, 150°C / 2h, 180°C / 2h, 200°C / 1h, 230°C / 2h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com