A silicon-rich soil conditioner and its preparation method and application

A soil conditioner and silicon-rich technology, which can be used in applications, soil conditioning materials, chemical instruments and methods, etc., can solve the problem of low utilization rate of calcium-rich substances, and achieve increased plant phosphorus utilization, low cost, and increased plant growth. The effect of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] All four sources of calcium were treated with concentrated monosilicic acid containing 15% silicon, and the ratio of calcium-rich material: silicon material for each treatment was 10:1. The treatment process includes the following steps:

[0043] The first step: crush the above four calcium-rich materials with a standard pulverizer until the particle size is less than 2 mm;

[0044] The second step: mixing the crushed calcium-rich material and the mineral material with a monosilicic acid content of 15% in a weight ratio of 10:1;

[0045] Step 3: Add 50% by weight of pure water to the mixture under the conditions of normal pressure, humidity 50%, and temperature 0-100°C, cultivate for one week, and stir for 15 minutes every day;

[0046] Step 4: Put the cultured mixture in an oven at 65°C to dry until the moisture content is 5-8%;

[0047] Step 5: Grind and pass through a 1mm sieve.

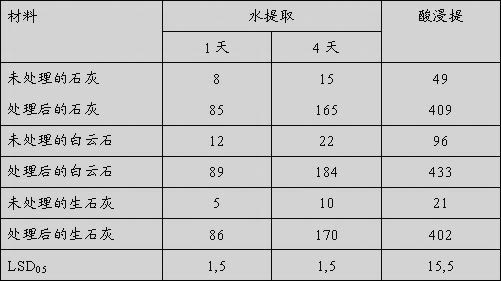

[0048] The silica content was determined by water and acid extraction by the followi...

Embodiment 2

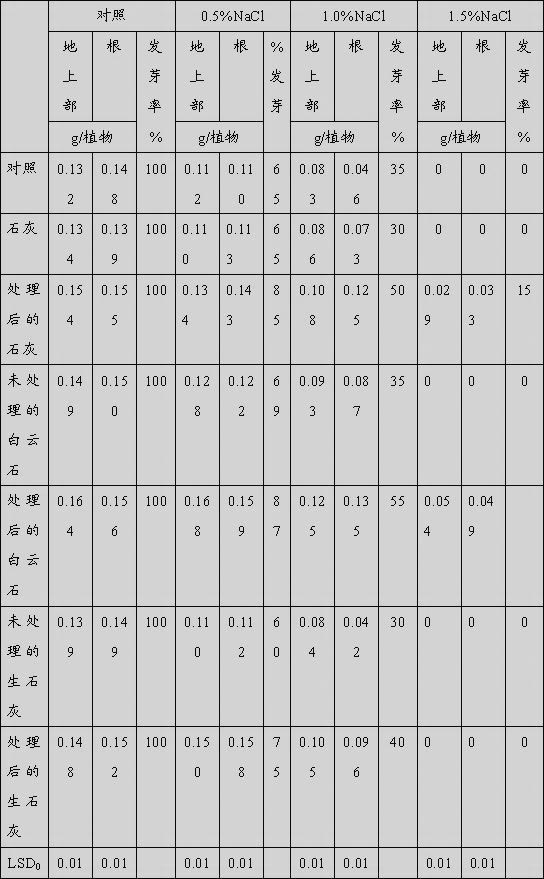

[0063] Culture tests with treated and untreated calcium-rich materials and soils were carried out at the Institute of Basic Biological Problems of the Russian Academy of Sciences. Lime and gypsum were used as calcium-rich substances in this experiment. The treatment process includes the following steps:

[0064] Step 1: Pulverize the calcium-rich material to a particle size smaller than 2 mm;

[0065] The second step: mix calcium-rich and silicon-rich substances in a weight ratio of 10:1, the silicon-rich substance is concentrated monosilicic acid with 15% silicon or amorphous silicon dioxide chemically pure gas phase II produced by Russia Akkord Co., Ltd. Silicon oxide (SiO 2 -3), 0.007-0.030μm particle size, white, CAS 112945-52-5, pH 6.9 treatment;

[0066] The third step: under normal pressure, humidity 5-95%, temperature 20-24°C, add 50% by weight pure water to the mixture uniformly mixed in the second step, and cultivate for 1 day;

[0067] Step 4: Dry in an oven at ...

Embodiment 3

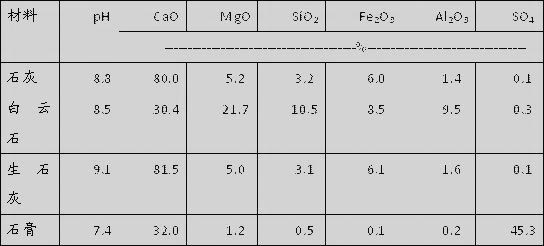

[0091] The second greenhouse experiment was carried out at the Institute of Basic Biological Problems of the Russian Academy of Sciences. The main purpose of this experiment was to determine the effect of treated and untreated calcium-rich substances on the biomass and phosphorus and iron uptake of barley acid-alkaline soil. Two calcium-rich substances, lime and gypsum, were used in the experiment. The chemical compositions of these substances are listed in Table 1.

[0092] The cultivation experiments with treated and untreated calcium-rich materials and soils were organized and carried out at the Institute of Basic Biological Problems of the Russian Academy of Sciences. Lime and gypsum were used as calcium-rich substances in this experiment. The treatment process includes the following steps:

[0093] Step 1: The calcium-rich material is pulverized with a standard pulverizer until the particle size is less than 2 mm;

[0094] The second step: mix the calcium-rich material...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com