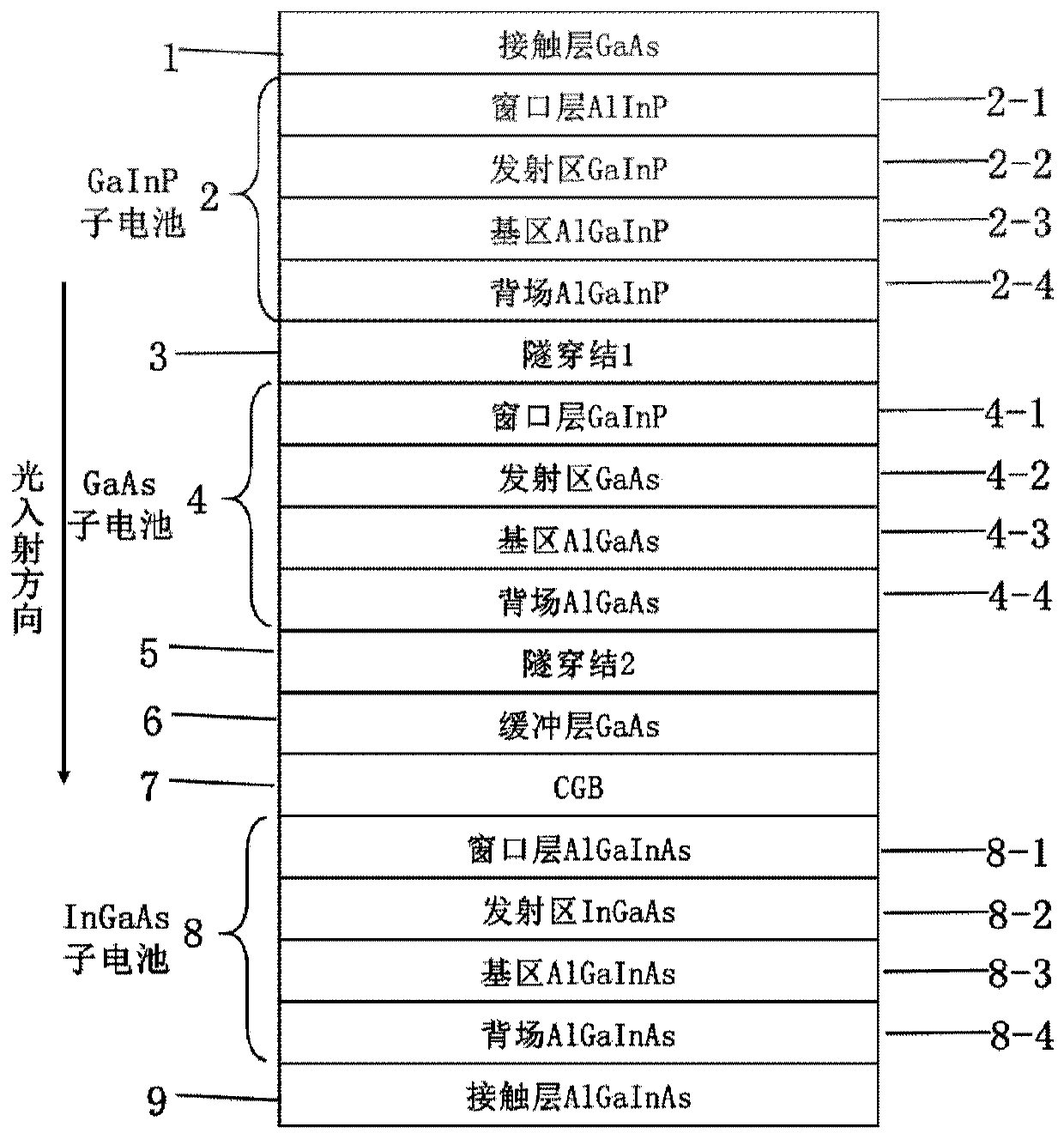

GaInP/GaAs/InGaAs three-junction film solar cell

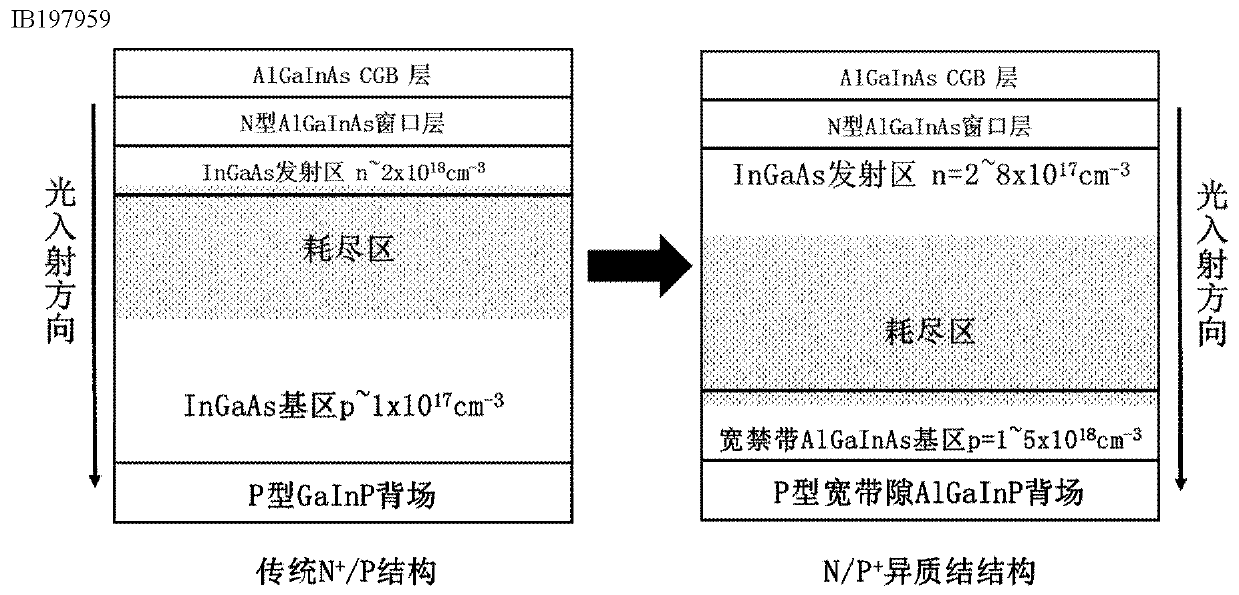

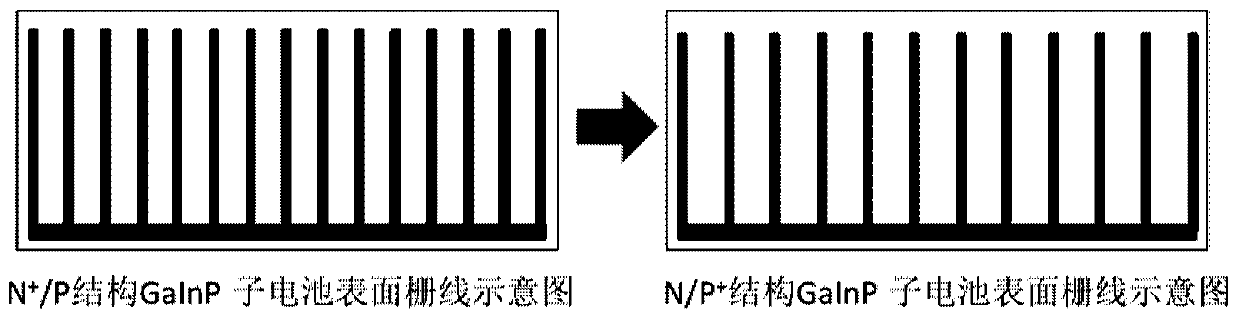

A thin-film solar cell and battery technology, applied in the field of solar cells, can solve problems such as cell gaps, and achieve the effects of reducing defect density, reducing compound current, and increasing short-circuit current.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] An N-type GaAs substrate is used as a substrate, on which an AlAs lift-off sacrificial layer is epitaxially grown, and then layers 1 to 9 are epitaxially grown in sequence. in:

[0054] The GaInP top cell window layer is made of Si-doped AlInP with a doping concentration of 1x10 18 cm -3 , with a thickness of 30nm; the emission region is made of Si-doped GaInP with a doping concentration of 5x10 17 cm -3 , with a thickness of 500nm; the base region is made of Zn-doped Al 0.15 GaInP with a doping concentration of 2x10 18 cm -3 , the thickness is 50nm; the back field uses Zn-doped AlGaInP, the thickness is 50nm, the Al composition in the material increases linearly from 0.15 to 0.25 from the interface of the base region, and the doping concentration increases from 1x10 18 cm -3 Exponent increased to 5x10 18 cm -3 .

[0055] The cell window layer in GaAs is made of Si-doped GaInP with a doping concentration of 2x10 18 cm -3 , with a thickness of 30nm; the emiss...

Embodiment 2

[0060] An N-type GaAs substrate is used as a substrate, on which an AlAs lift-off sacrificial layer is epitaxially grown, and then layers 1 to 9 are epitaxially grown in sequence. in:

[0061] The GaInP top cell window layer is made of Si-doped AlInP with a doping concentration of 1x10 18 cm -3 , with a thickness of 30nm; the emission region is made of Si-doped GaInP with a doping concentration of 2x10 17 cm -3 , with a thickness of 700nm; the base region is made of Zn-doped Al 0.25 GaInP with a doping concentration of 2x10 18 cm -3 , the thickness is 50nm; the back field adopts Zn-doped AlGaInP, the thickness is 50nm, the Al composition in the material increases linearly from 0.25 to 0.5 from the interface of the base region, and the doping concentration increases from 1x10 18 cm -3 Exponent increased to 3x10 18 cm -3 .

[0062] The cell window layer in GaAs is made of Si-doped GaInP with a doping concentration of 2x10 18 cm -3 , with a thickness of 30nm; the emis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com