Steel pipe connector of ladder-type sleeper for railway track

A technology for connecting parts and steel pipes, which is used in the direction of roads, tracks, buildings, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

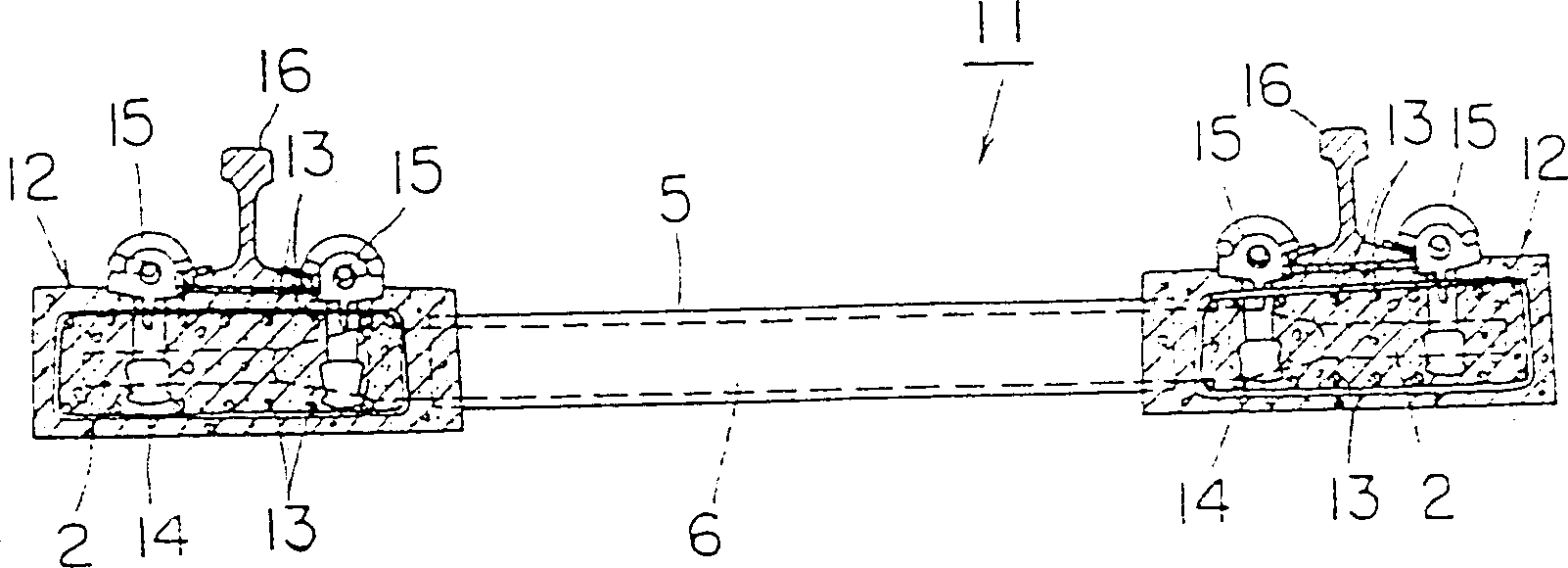

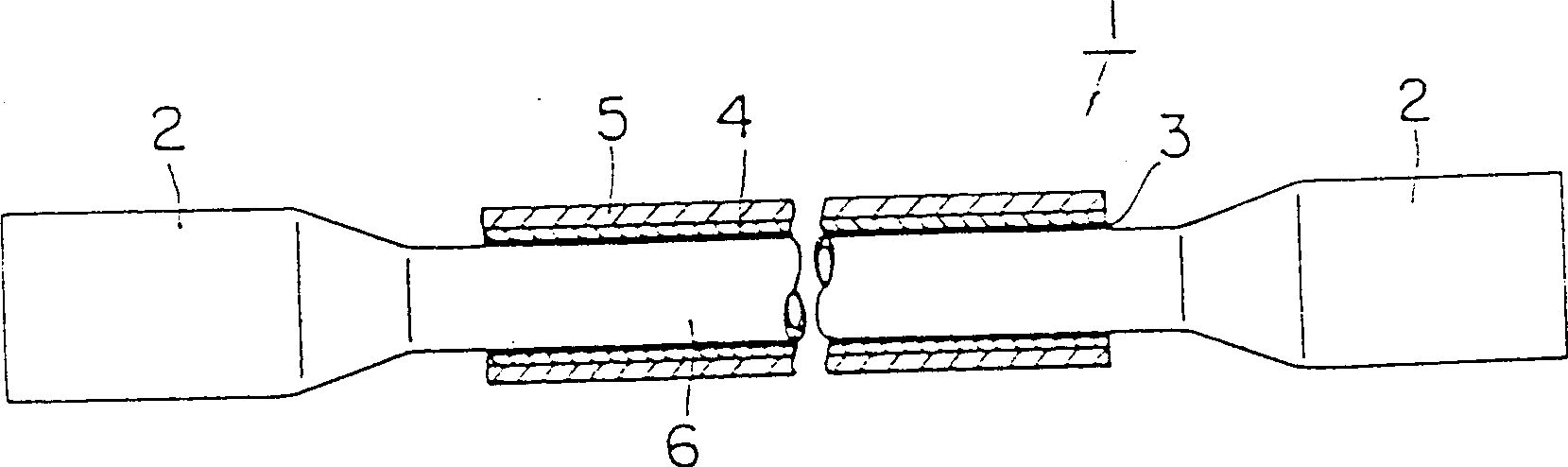

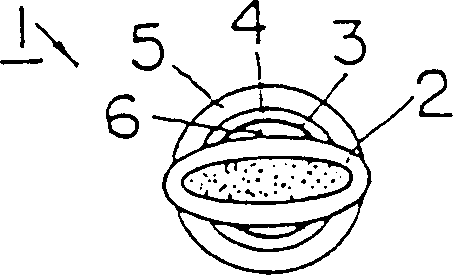

[0025] The following combination figure 1 And Fig. 2 specifically introduces the steel pipe connector of the railway rail ladder frame sleeper as described in the present invention. figure 1 It is a structural cross-sectional view of a railway rail ladder frame sleeper, which adopts the steel pipe connector according to the present invention, Figure 2(a) and 2(b) Represent the steel pipe connector according to the present invention, wherein, Fig. 2 (a) is a plan view omitting a certain section of its middle part, and Fig. 2 (b) is a front view of the steel pipe connector according to the present invention.

[0026] see Figure 2(a) and 2(b) , the identifier 1 indicates a steel pipe connector made of small-diameter thick-walled steel pipe 6, the two ends of the steel pipe 6 are flattened to form a flattened part 2, and the thickness of the straightened part 2 is 1 / 2 of the height of the outer diameter in the horizontal direction , the outer surface of the middle part of ...

Embodiment 2

[0031] Steel pipe connectors play the role of connecting concrete longitudinal beams and structural constraints in railway rail ladder sleepers. This specification proposes two examples of steel pipe connectors, one adopts a conventional structure and the other is as described in the present invention. Among them, the structural features of conventional steel pipe connectors are as follows: the rib is H-shaped, its thickness is 6 mm, and its width is 30 mm. The material used is ordinary rolled structural steel SS 400 in JIS G3101. The rib is 50 mm The length up to 300 mm is welded to the sides of the two ends of the small-diameter thick-walled steel pipe 6. The outer diameter of the small-diameter thick-walled steel pipe is 76.3 mm, the wall thickness is 9 mm, and the length is 1476 mm. The material used is ordinary carbon in JIS G3444. The pipe material of structural steel STK540; the middle part of the steel pipe connector is coated with a cured rubber coating on the length o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com