Gelatin polymer derived from natural sources of cold-adapted marine species and uses thereof

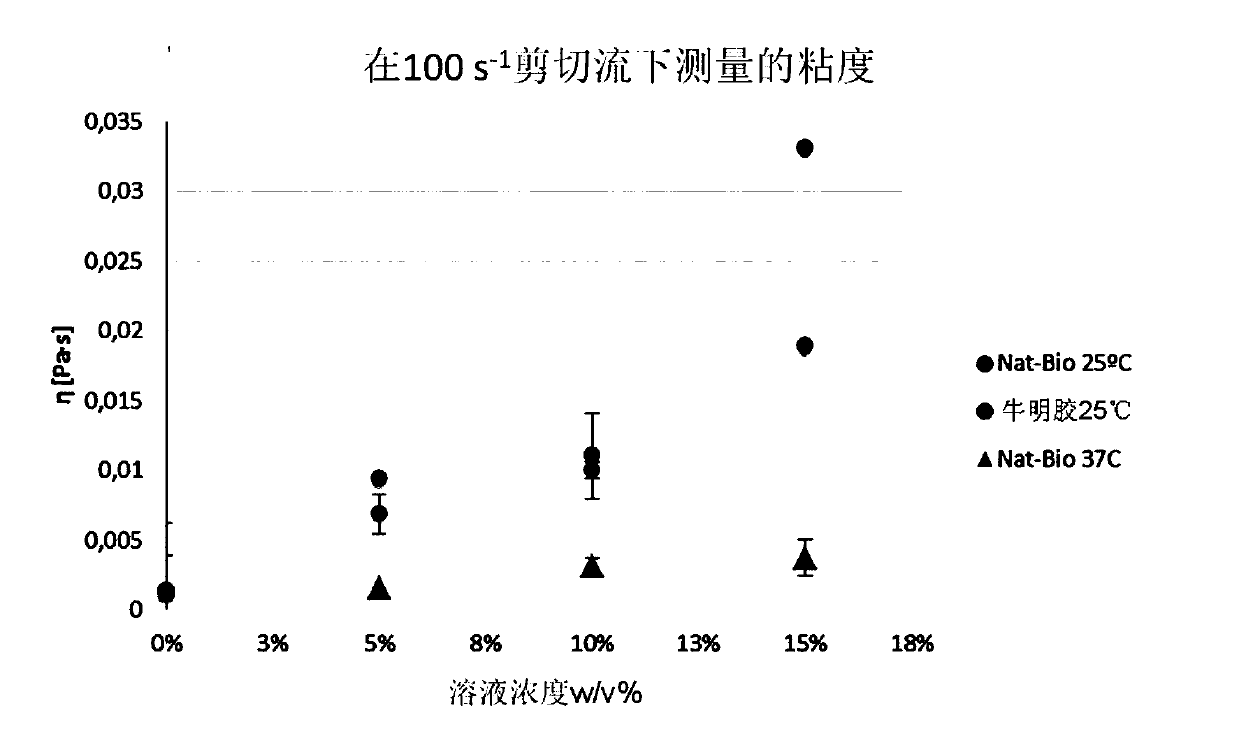

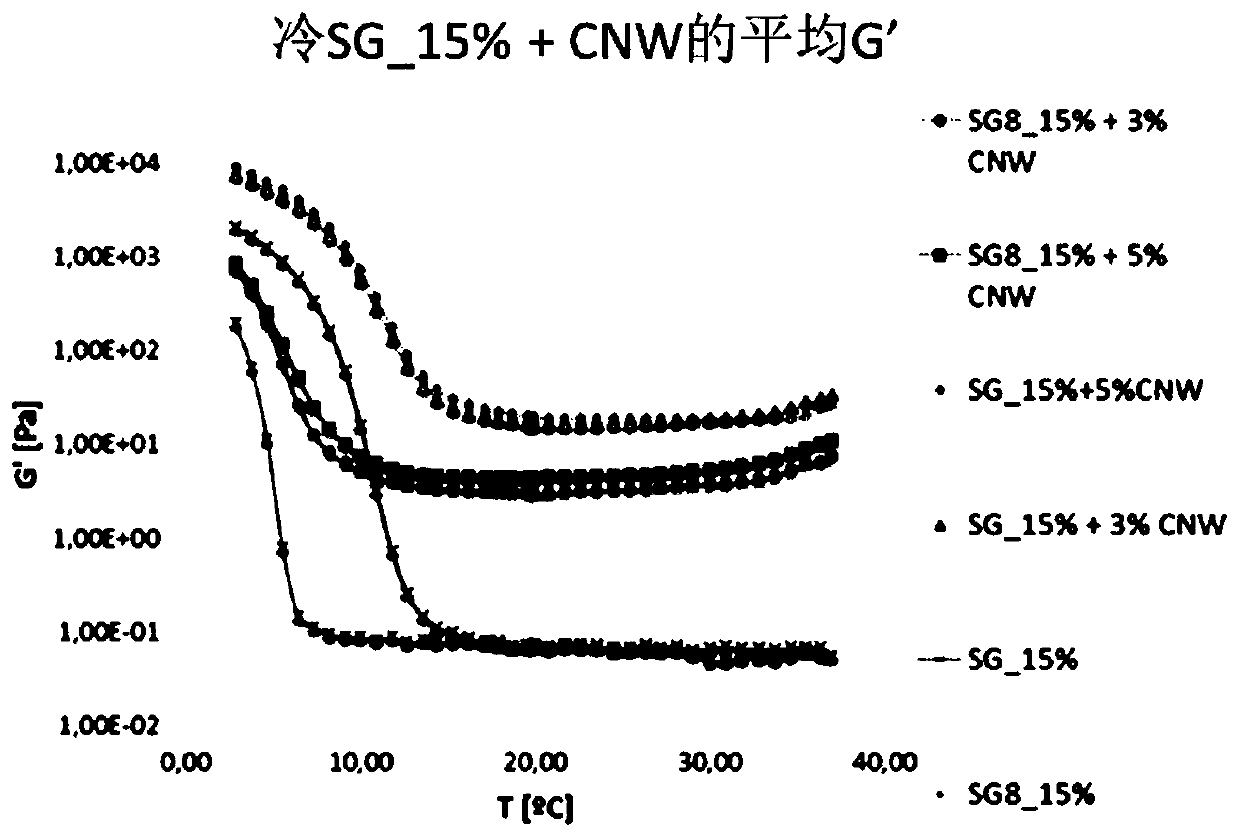

A natural source, polymer technology, applied in the preparation, application, and peptide source of animal glue or gelatin, which can solve problems such as poor rheological properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0197] Example 1. Preparation of methacryloyl salmon gelatin solution.

[0198] - Extraction of salmon gelatin:

[0199] 1. Remove any remaining flesh and scales from the salmon skin.

[0200] 2. Cut the skin into small squares (3-5cm / side)

[0201] 3. Add 6 mL of 0.1 M NaOH per gram of skin and maintain constant stirring (9000 rpm) for 1 hour at 10°C. →6mL / g*500g=3L (measured pH=13)

[0202] 4. Remove the solution and wash with dH 2 O Wash the skin by filtering and soaking.

[0203] 5. Add 6 mL of 0.1M NaOH per gram of skin and keep stirring at 10°C for 1 hour. → 3L (measured pH = 13)

[0204] 6. Remove the solution and filter through dHO 2 O washes the skin with dH 2 O Rinse and soak the filtered skin.

[0205] NOTE: Too much washing at this step may affect the pH of the acidic solution in step 7, which may lead to higher acidity and thus induce partial extraction of gelatin which needs to be avoided at this stage.

[0206] 7. Then, add 6 mL of 0.05M CH per gram ...

Embodiment 2

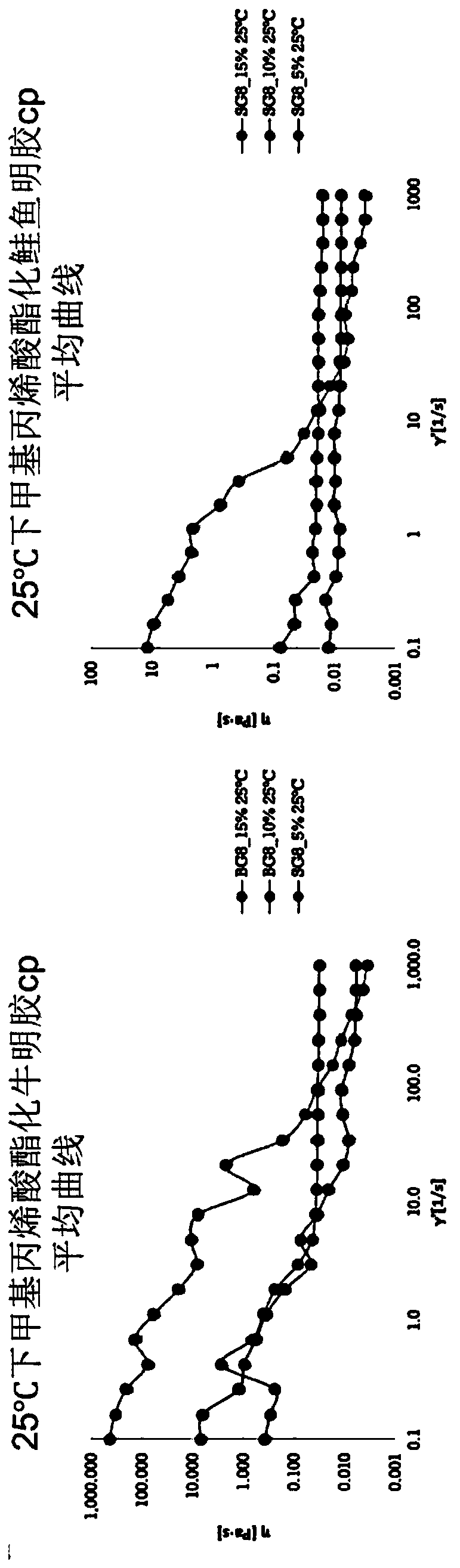

[0217] Example 2. Preparation of methacryloyl bovine gelatin solution.

[0218] Similar to Example 1, after mixing with methacrylic anhydride and reacting with amino groups (mainly lysine) in gelatin solution, as previously described (Nichol et al. 2010; Van Den Bulcke et al. 2000). , Synthesis of methacryloyl bovine gelatin. Briefly, bovine gelatin (Bloom 220, Rousselot, The Netherlands) was dissolved in PBS 1X (pH 7.4) at 60°C to a final concentration of 10% (w / v). After complete dissolution, while still stirring, methacrylic anhydride (276685, Sigma, USA) was slowly added to a final concentration of 8% (v / v). Different levels of methacryloyl functionalization require different concentrations of methacrylic anhydride. After 3 hours of reaction, a 5X dilution was made in PBS 1X, and the reacted gelatin was dialyzed against deionized water at 40°C for 1 week. Fresh deionized water was changed daily to remove all unreacted methacrylic anhydride during dialysis. Finally, the...

Embodiment 3

[0219] Example 3. Preparation of non-methacryloyl salmon gelatin solution.

[0220] Salmon gelatin was extracted according to the instructions in Example 1, and non-methacryl salmon was usually prepared by dissolving the obtained gelatin in PBS 1X (pH 7.4) at 60°C to a final concentration of 10% (w / v) gelatin. Solutions of different concentrations of gelatin required dissolving different amounts of ground gelatin in PBS 1X.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

| compressive modulus | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com