Integrated control system of electrolytic water hydrogen production and alloy hydrogen storage

An integrated control system and water electrolysis technology, applied in electrolysis components, electrolysis process, piping system, etc., can solve the problems of difficult heat dissipation, high energy consumption, reduced hydrogen storage capacity and hydrogen absorption speed, etc., to improve the heating and cooling efficiency, The effect of high operating efficiency and fast heating and cooling speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

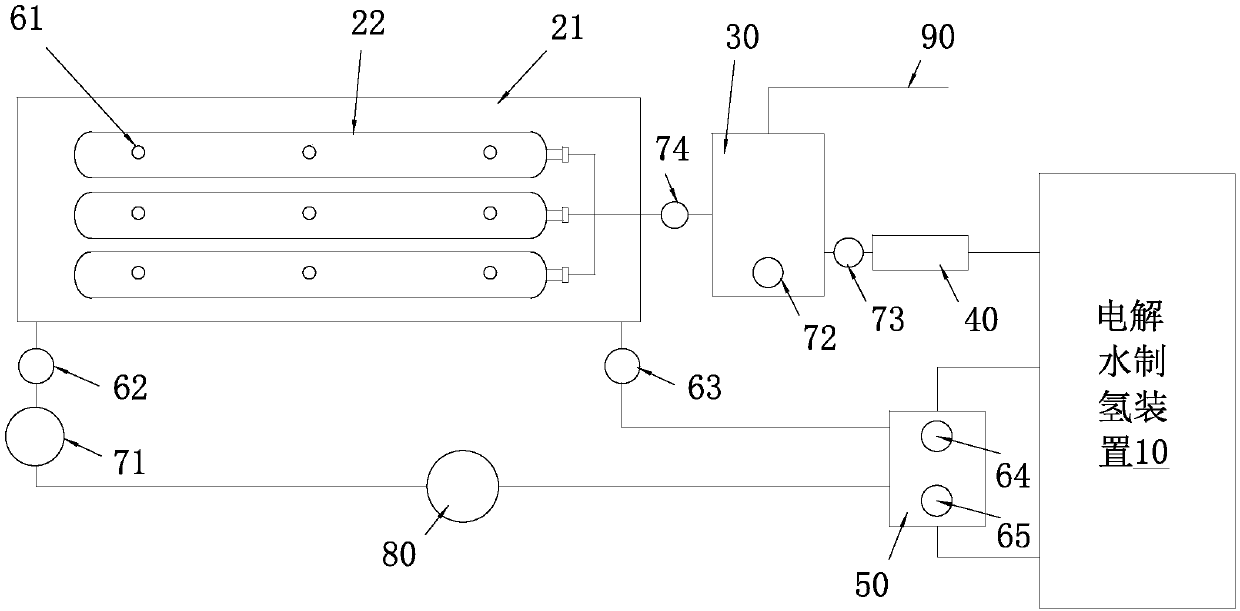

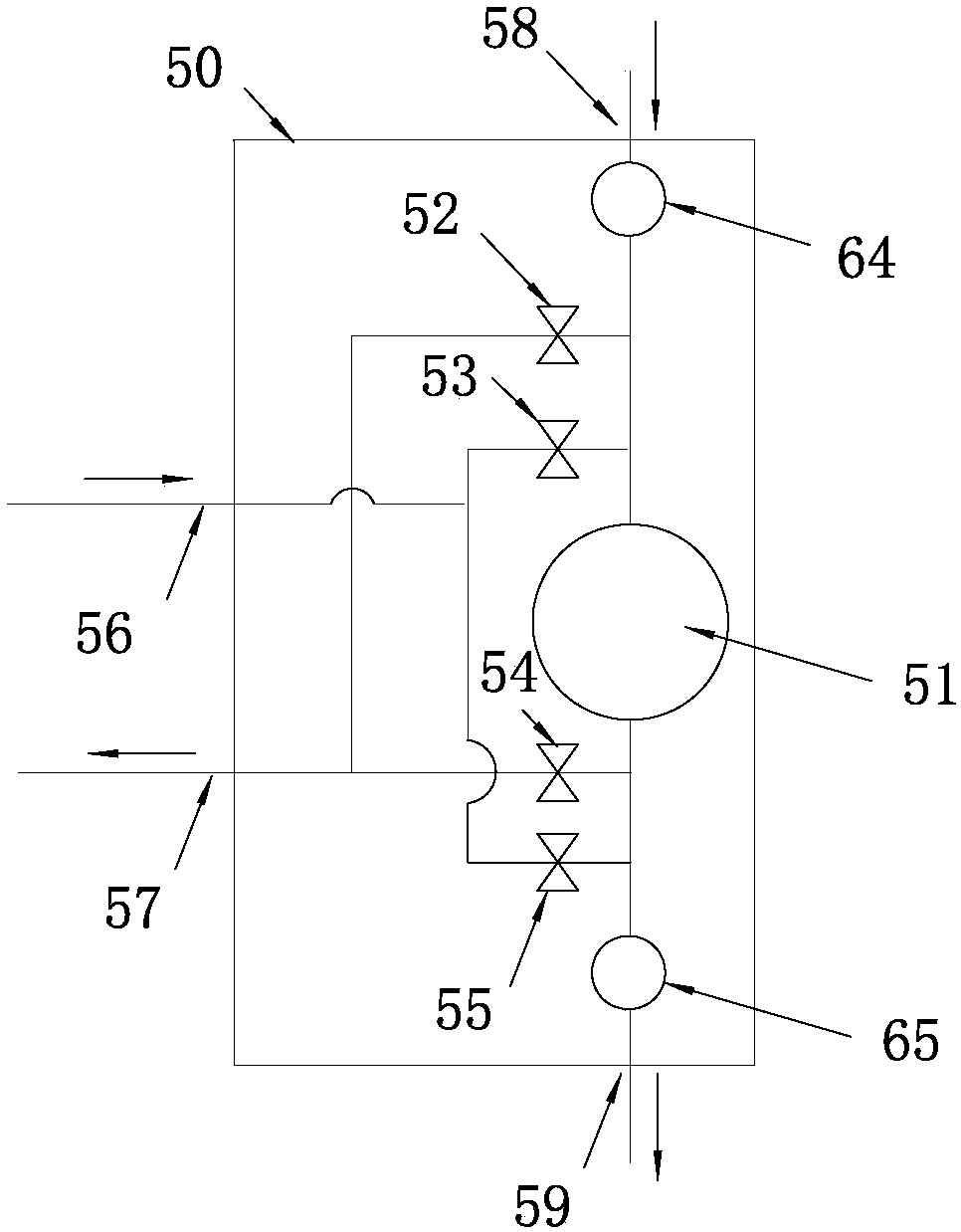

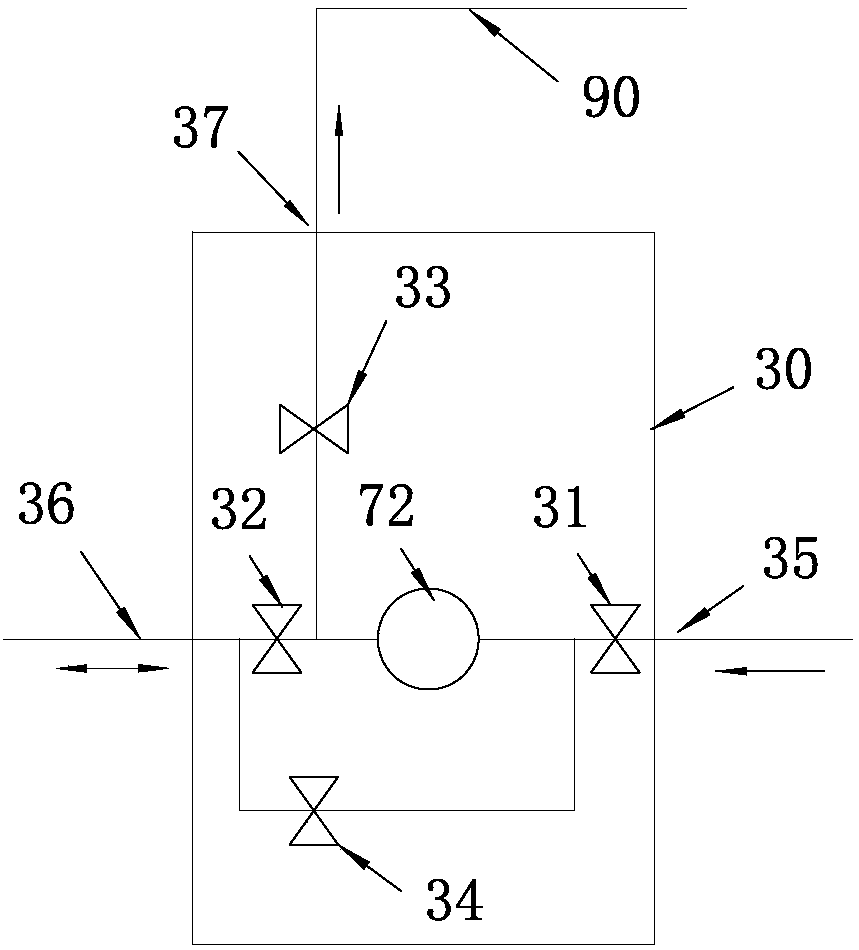

[0014] Such as Figure 1 to Figure 3 As shown, the integrated control system for electrolytic water hydrogen production and alloy hydrogen storage of the present invention includes an electrolytic water hydrogen production device 10, and the hydrogen production outlet of the electrolytic water hydrogen production device 10 passes through the hydrogen production tank 40 and the explosion-proof hydrogen suction and discharge control cabinet 30. The inlet is connected, and the storage tank interface of the explosion-proof hydrogen absorption and discharge control cabinet 30 is connected with the tank ports of several hydrogen storage tanks 22 placed in the antifreeze liquid in the hydrogen storage water bath 21. The hydrogen storage tanks 22 are filled with hydrogen storage alloys, and the explosion-proof suction The hydrogen output port of the hydrogen discharge control cabinet 30 is connected with a hydrogen output pipeline 90, the antifreeze outlet of the hydrogen storage water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com