Thermal conductivity test platform based on visual planar heat pipe and test method thereof

A test platform and test method technology, applied in the direction of measuring device, material thermal development, material excitation analysis, etc., can solve the problem of inaccurate thermal conductivity test, achieve the effect of reducing design test cost, high flow speed, and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] For a better understanding, the embodiments of the present invention are explained in detail with reference to the accompanying drawings.

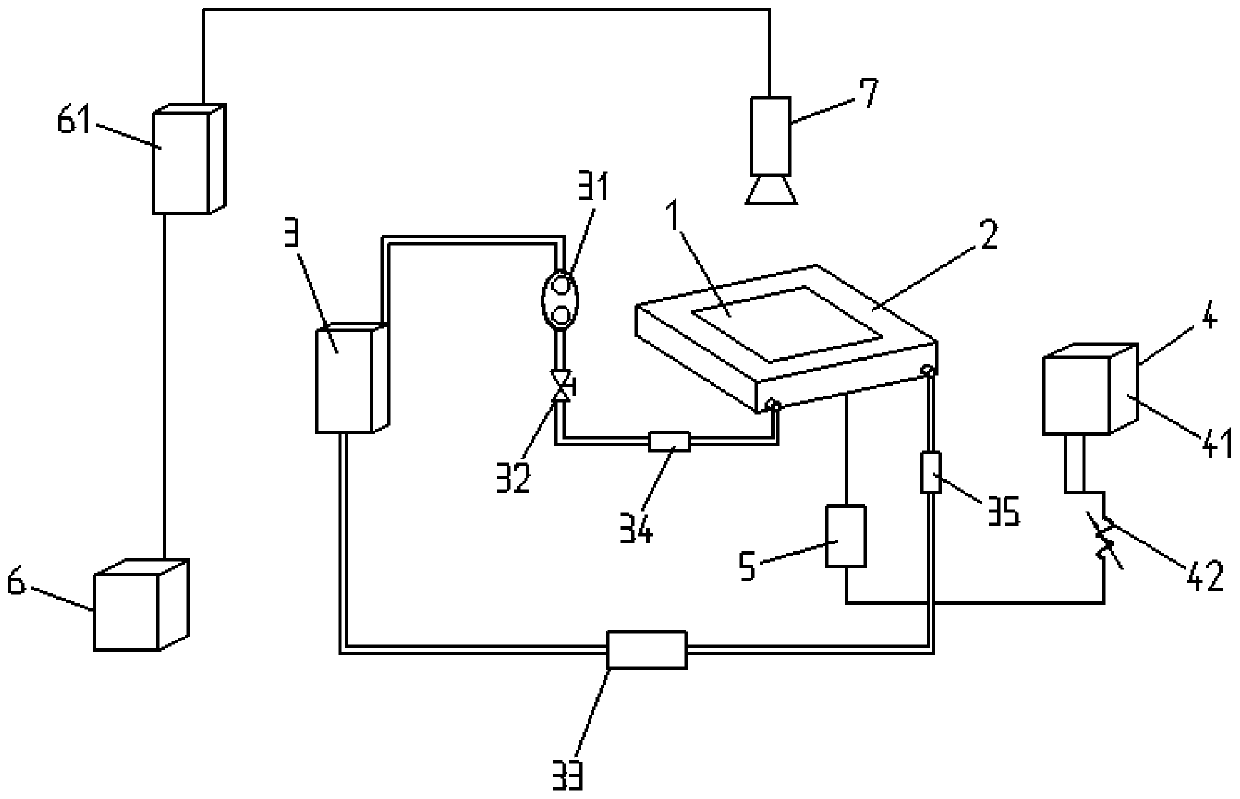

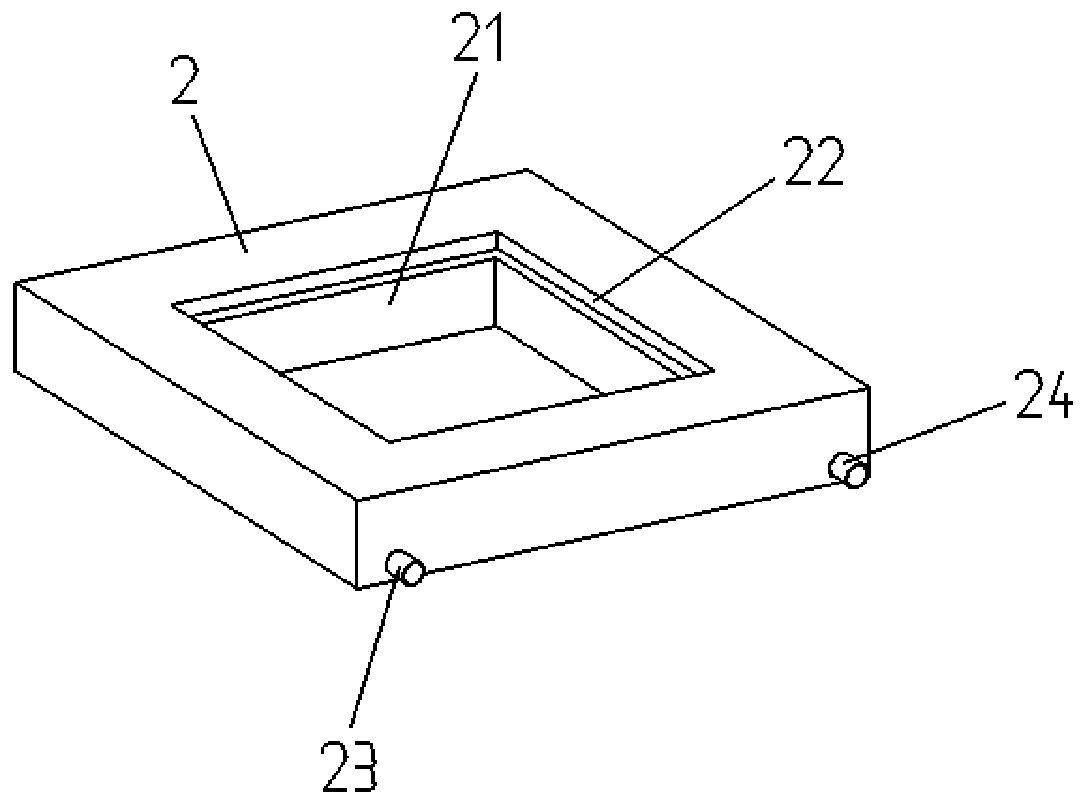

[0050] Such as Figures 1 to 4 As shown, a thermal conductivity test platform based on a visual planar heat pipe includes a working module and a measurement module. The working module and the measurement module are arranged separately. Base diode 8, constant current voltage source 4, programmable relay 5 and cooling water tower 3;

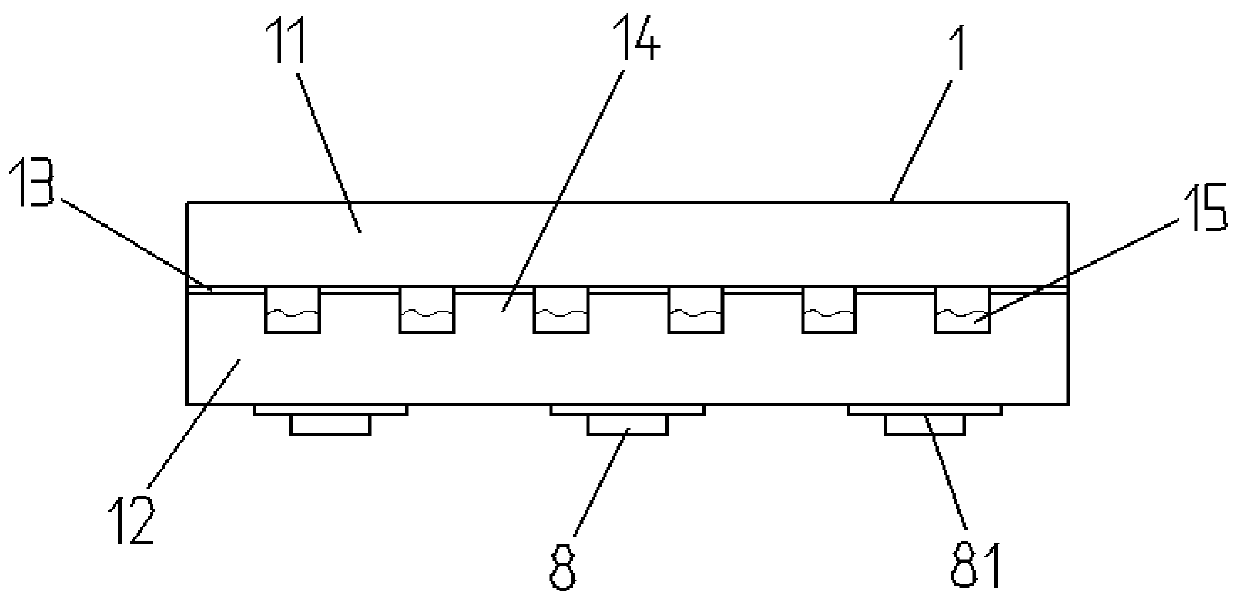

[0051] The planar heat pipe 1 includes a 0.35 mm thick SiC wafer 12 arranged at the bottom, a plurality of hexagonal micropillars 14 uniformly etched on the SiC wafer 12, and a heat exchange working fluid 15 located outside the hexagonal micropillars 14 And the 0.5mm thick glass wafer 11 on the top, the glass wafer 11 is combined with the SiC wafer 12 using a gold-gold bonding process with a gold coating 13 of 2 μm, and the hexagonal micropillars 14 are evenly arranged in a honeycomb shape;

[0052] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com