Method for manufacturing packing material of optical member

A technology of optical components and manufacturing methods, which is applied to optical elements, optics, nonlinear optics, etc., can solve the problems of poor handling of optical components, biting air bubbles, etc., and achieve good handling effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

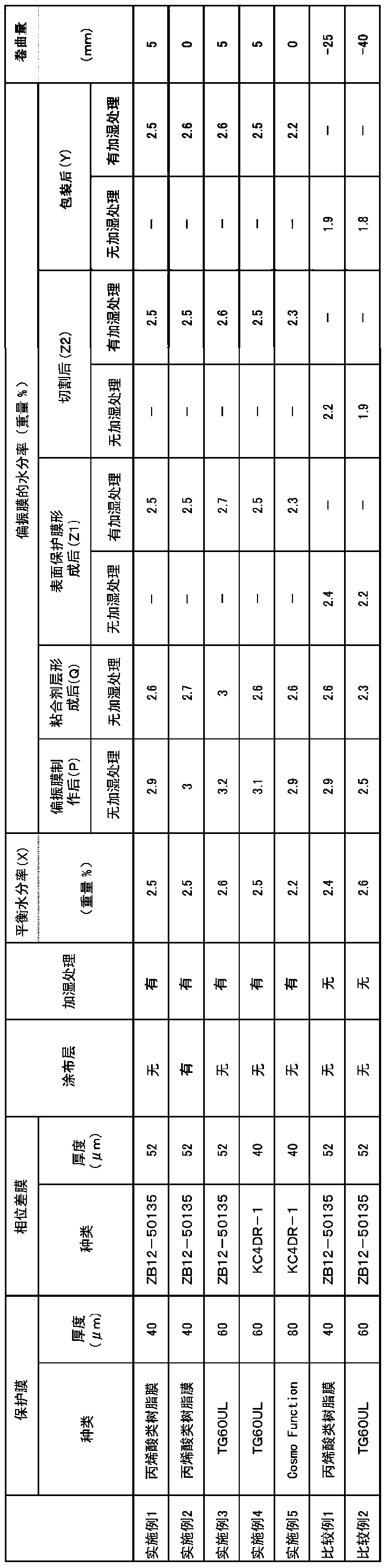

Embodiment 1

[0094]

[0095] A corona-treated protective film and a phase difference film (manufactured by ZEON Corporation, trade name: ZB12-50135, thickness: 52 μm) were used on the easily-adhesive surface of an acrylic resin film having a lactone ring structure with a thickness of 40 μm. On the bonding surface, the above-mentioned ultraviolet curable adhesive was applied so that the cured thickness became 0.7 μm, and they were combined with a polarizing plate (manufactured by Kuraray Co., Ltd., trade name: PS4500, thickness: 45 μm) with a roll mill. face fit. Thereafter, ultraviolet rays are irradiated to cure the adhesive to produce a polarizing film. Then, when the equilibrium moisture content of the produced polarizing film was measured by the following method, the equilibrium moisture content X in the atmosphere of temperature 20 degreeC and relative humidity 55 %Rh was 2.5 weight%.

[0096] (Measurement of Equilibrium Moisture Content X of Polarizing Film)

[0097] Three sample...

Embodiment 2~5、 comparative example 1~2

[0136] In Example 1, as shown in Table 1, the type and thickness of the protective film, the type and thickness of the retardation film, and the presence or absence of humidification treatment were changed, and an optical member was produced in the same manner as in Example 1, And pack it. Moreover, the moisture content of each polarizing film was measured similarly to Example 1.

[0137] In addition, the coating layer of Example 2 was formed by the following method.

[0138] Prepare 50 parts by weight of ultraviolet curable urethane acrylate resin (manufactured by Nippon Synthetic Chemical Industry Co., Ltd., trade name "UV1700B", solid content 100%), and a multifunctional acrylate mainly composed of pentaerythritol triacrylate (Osaka Organic Chemical Industry Co., Ltd. product, brand name "VISCOAT #300", solid content 100%) 50 parts by weight. With respect to 100 parts by weight of the resin solid content of the above resin, copolymerized particles of acrylic acid (Japanes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com