Acrylamide copolymer, and preparation method and application thereof

A technology of acrylamide copolymer and acrylamide copolymerization, which is applied in the application field of acrylamide copolymer to achieve the effects of good temperature and salt resistance, high molecular weight and low residual monomer content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

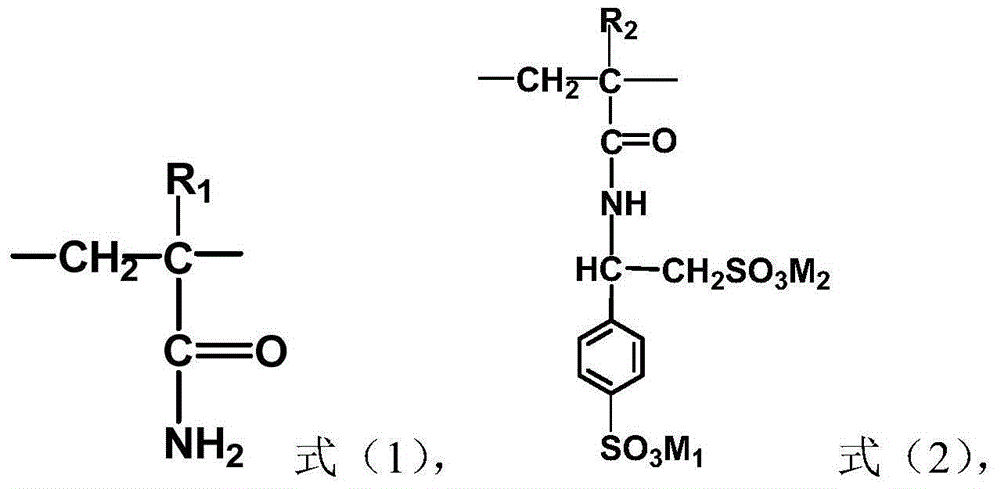

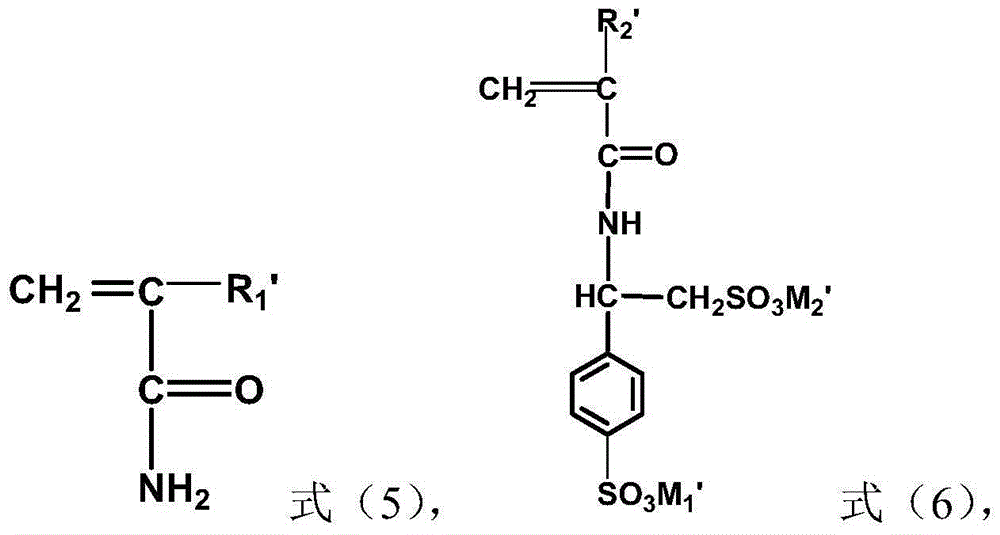

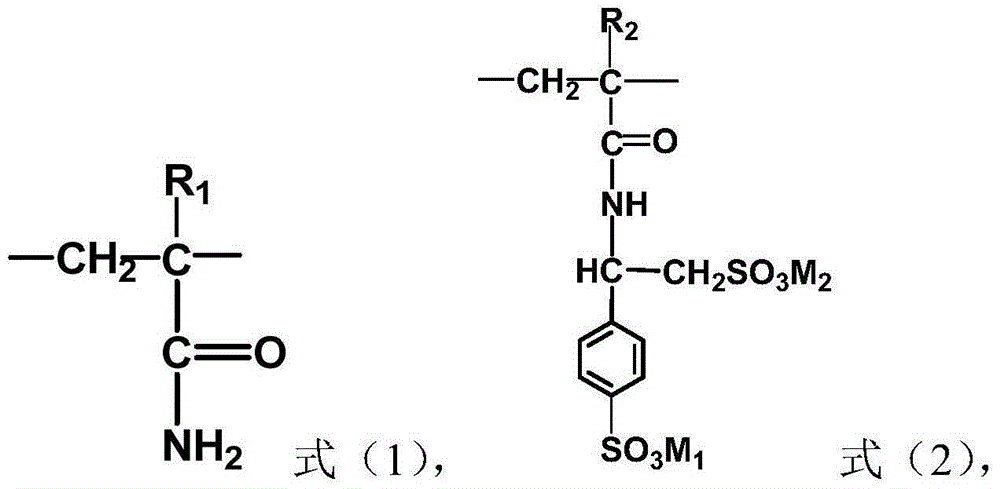

[0033] The present invention also provides a method for preparing an acrylamide copolymer, the method comprising: polymerizing a monomer mixture in water under solution polymerization conditions and in the presence of an initiator; wherein the monomer The mixture contains monomers of structure shown in formula (5) and monomers of structure shown in formula (6); based on the total moles of monomers in the monomer mixture, the monomers of structure shown in formula (5) The content of the monomer is 1-99 mole %, the content of the monomer of the structure shown in formula (6) is 1-99 mole %; preferably, the content of the monomer of the structure shown in formula (5) is 80-97.5 mole %, The monomer content of the structure shown in formula (6) is 2.5-20 mol %; The condition of described solution polymerization reaction makes the viscosity average molecular weight of the polymer obtained after the polymerization reaction be 30 million-35.5 million, preferably 31 million-3500 Ten th...

Embodiment 1

[0105] Add 530 kg of acrylonitrile into a temperature-controlled glass reactor, and slowly add 100 kg of concentrated sulfuric acid with a concentration of 98% by weight to the acrylonitrile under stirring, and cool the mixed solution to -5°C. After stirring evenly, slowly Add 118.2 kg of styrenesulfonic acid to keep the temperature of the reaction system below 5°C. After reacting for 2 hours, an appropriate amount of water was added, and the reaction was continued for 2 hours at room temperature, and the pH value of the system was adjusted to 7 with sodium hydroxide, and then stood still, and crystals were precipitated. After filtering, washing and drying, the pure monomer P1 was obtained.

Embodiment 2

[0107]Add 1060 kg of acrylonitrile into the temperature-controlled glass reactor, and slowly add 117.6 kg of concentrated sulfuric acid with a concentration of 98% by weight to the acrylonitrile under stirring, cool the mixture to 5°C, stir well, and slowly add 118.2 kilograms of styrenesulfonic acid, keeping the temperature of the reaction system below 10°C. After reacting for 4 hours, an appropriate amount of water was added, and the reaction was continued for 4 hours at room temperature, and the pH value of the system was adjusted to 7 with potassium hydroxide, and then stood still, and crystals were precipitated. After filtering, washing and drying, the pure monomer P2 was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear viscosity | aaaaa | aaaaa |

| shear viscosity | aaaaa | aaaaa |

| shear viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com