Method for constructing water-circulation plant salinity gradient field testing ground

A technology for constructing methods and degree gradients, which is applied in botany equipment and methods, soil preparation methods, plant cultivation, etc., and can solve problems affecting test development, large fluctuations in test conditions, large changes in groundwater level and salinity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to achieve the above-mentioned purpose and effect, and to further understand the technical solution of the present invention, the preferred embodiments are enumerated below, and in conjunction with the accompanying drawings, the detailed description is as follows:

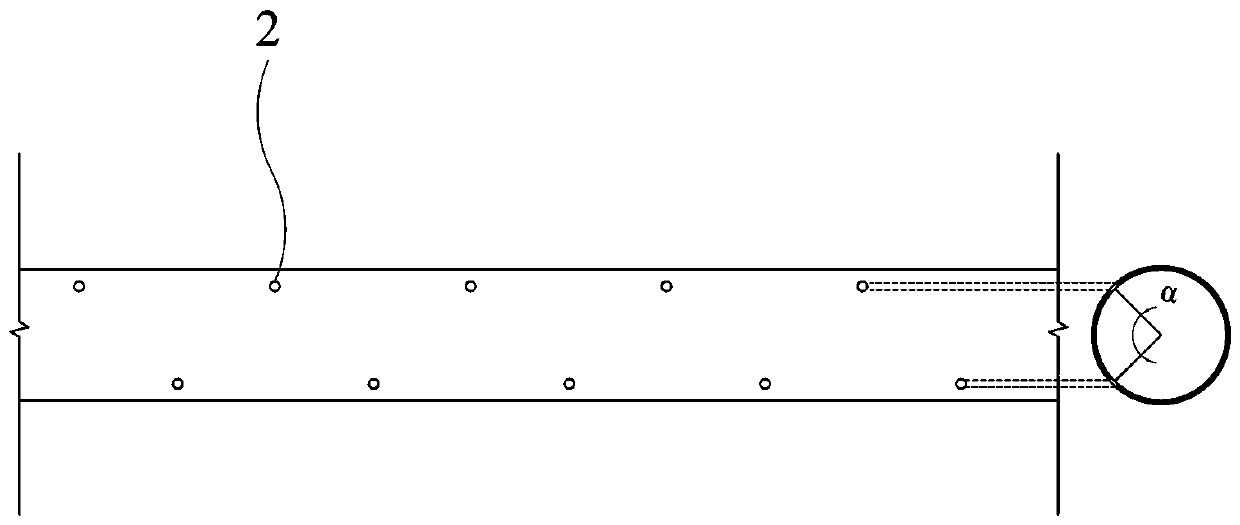

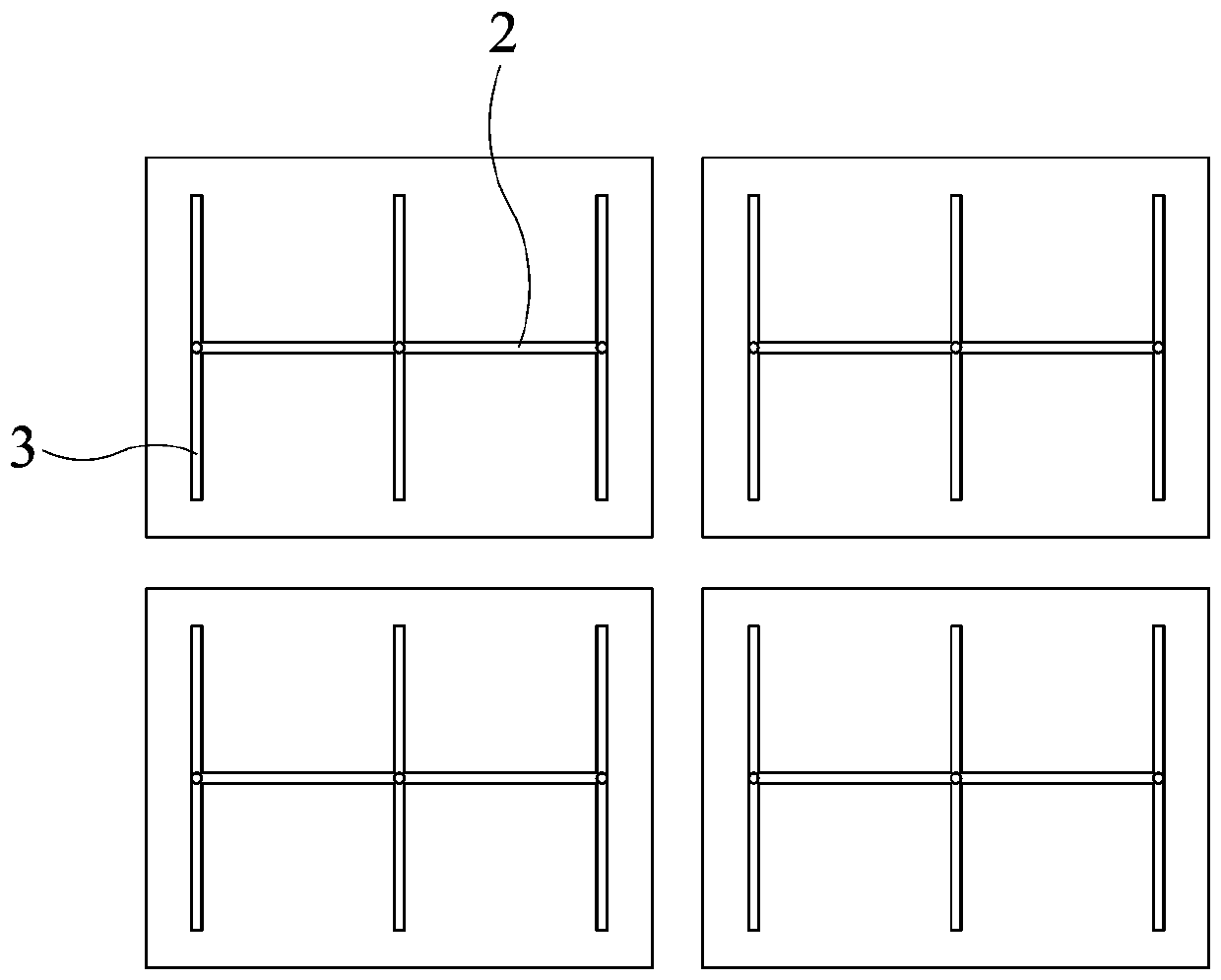

[0025] In the best embodiment of the present invention, the main construction process includes: mechanically digging the pond - laying the anti-seepage membrane - installing the seepage pipe - backfilling the planting soil - installing the water circulation system.

[0026] The specific implementation steps are as follows:

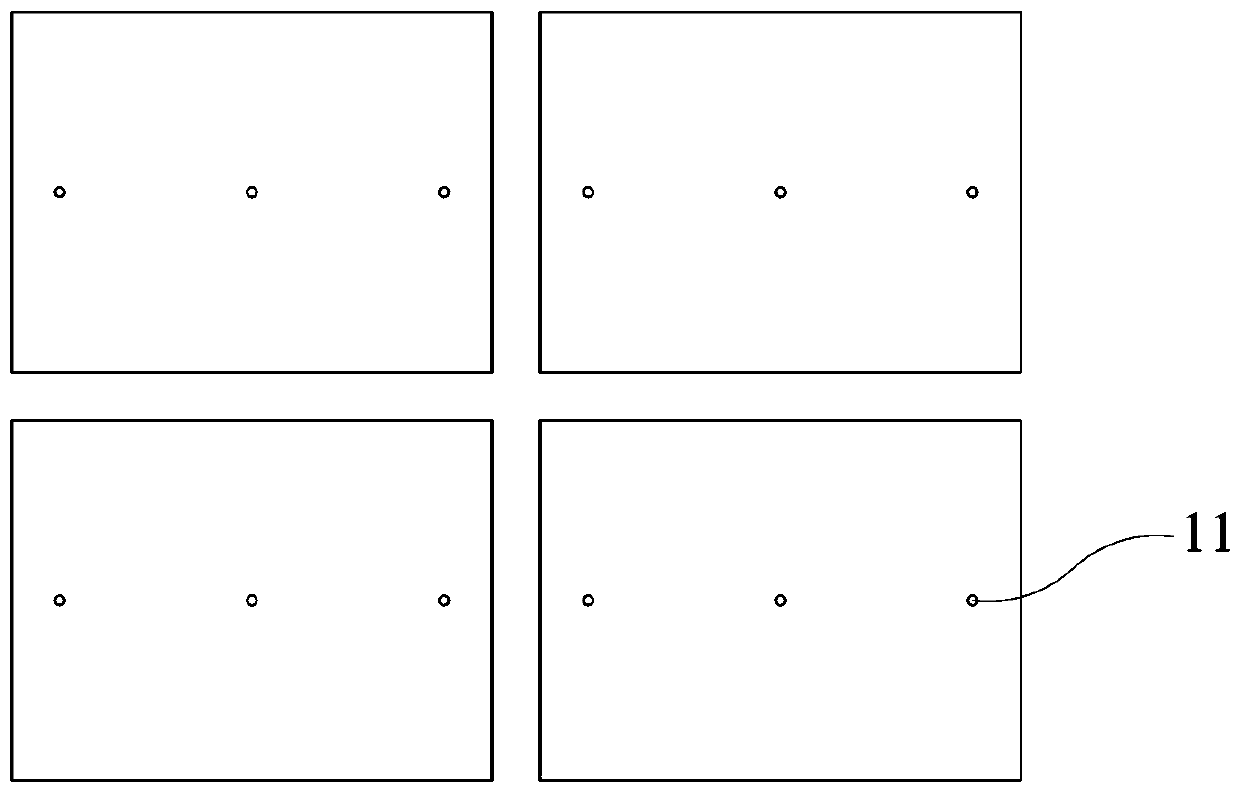

[0027] 1. Mechanical pond digging: Four rectangular ponds with a length of 10 m, a width of 7.5 m, and a depth of 1.5 m were dug in the selected experimental area with a wheeled excavator, and the excavated soil was piled up next to it for subsequent backfilling. The four pools are arranged in the shape of a "field", the width of the partition walls of the pools is about 50 cm, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com