Recycling method of fine cleaned coal

A technology for recovery of fine coal and slime, which is applied in chemical instruments and methods, wet separation, solid separation, etc., can solve problems such as increased cost, large loss rate of magnetic ore powder, and reduced yield of clean coal, achieving high precision Improvement, stable product quality, and increased productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

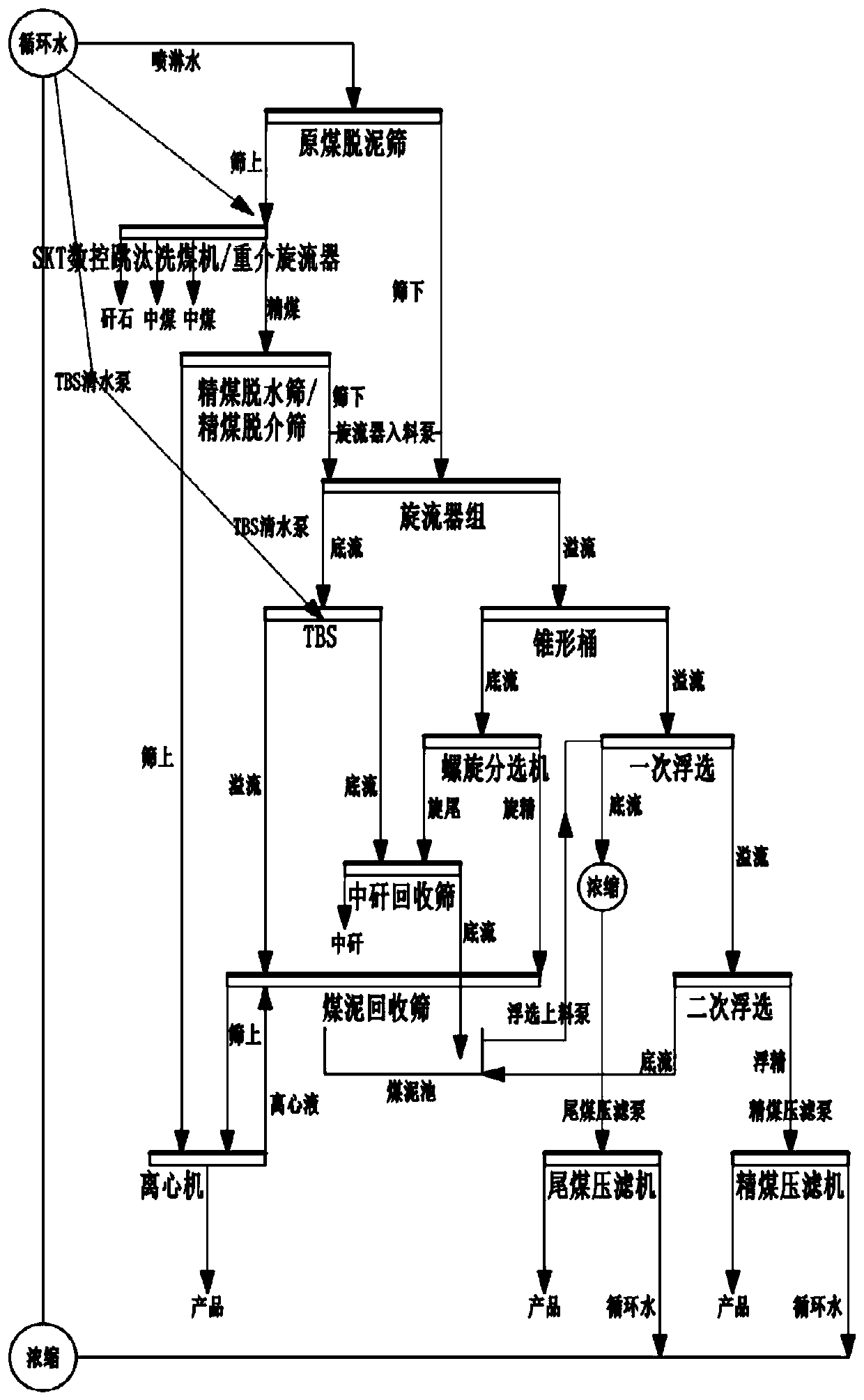

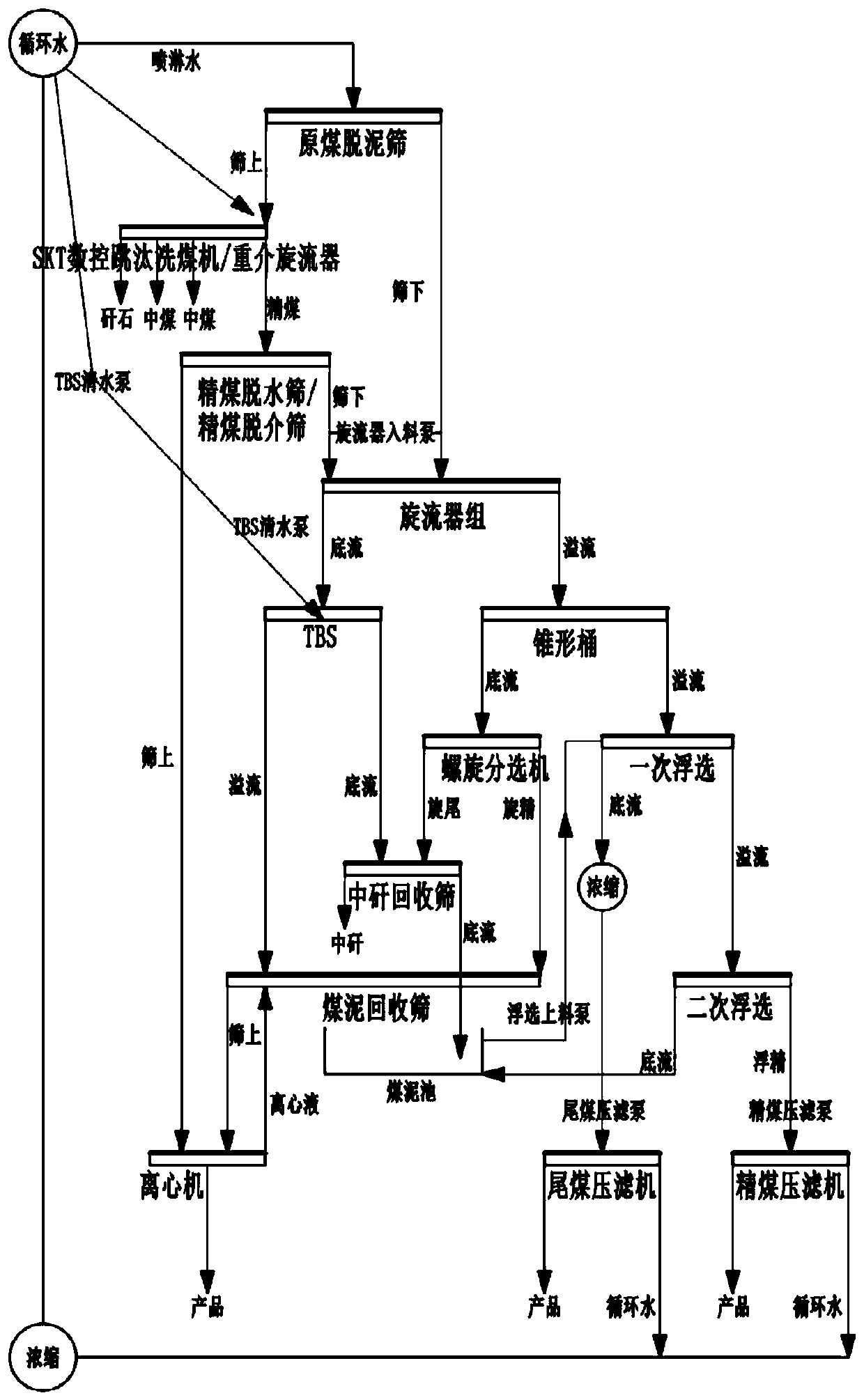

Method used

Image

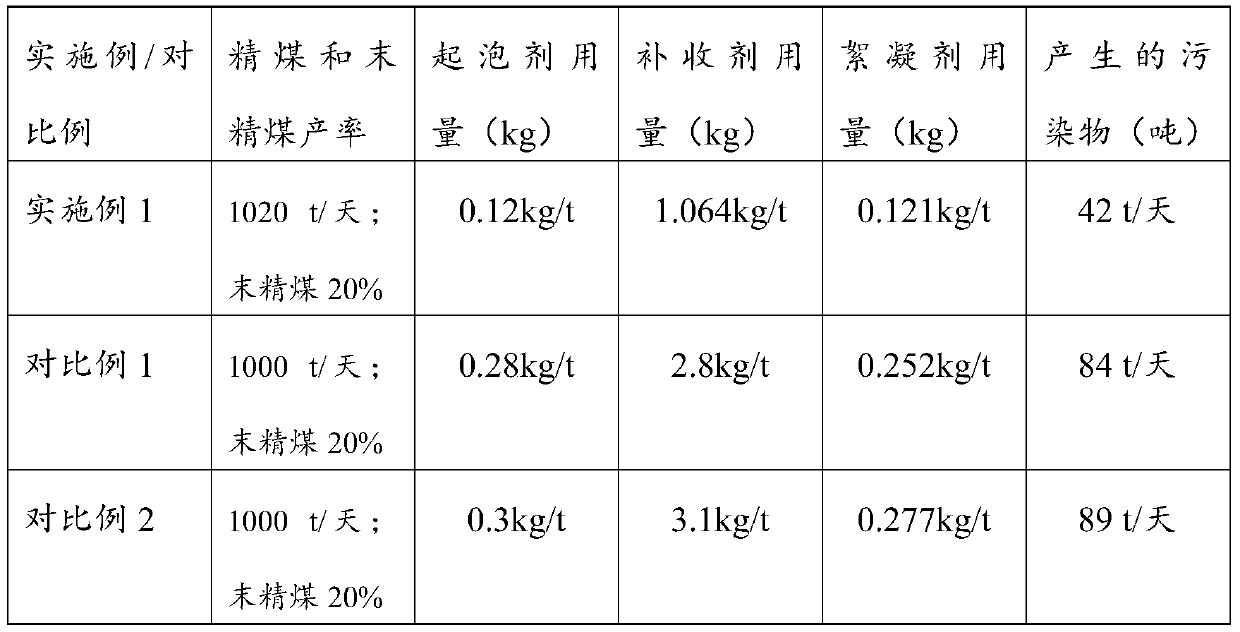

Examples

Embodiment 1

[0062] (1) Raw coal enters the buffer bin through the grading and crushing workshop, and a desliming screen with a sieve gap of 1.5mm is installed under the buffer bin to obtain the above-sieve material and the under-sieve material.

[0063] (2) Through the high-pressure spraying device (the pressure is 0.3MPa), the material on the screen of the desliming screen is washed into the jigging coal washing machine or the dense medium cyclone for coal preparation to obtain gangue, medium coal and clean coal;

[0064] (3) Wherein, the clean coal enters the clean coal dewatering screen or the clean coal de-intermediation screen to obtain the material on the screen and the material under the screen;

[0065] (4) The undersize material of the desliming screen, and the undersize material of the clean coal dehydration screen or the clean coal dewatering screen enter the cyclone group through the slurry pump for classification, and the particles with a particle size of 0.25-1.5 mm enter the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com