A leather automatic cutting system

A cutting system and fully automatic technology, applied in welding/cutting auxiliary equipment, auxiliary welding equipment, welding equipment, etc., can solve problems such as time-consuming and labor-intensive reduction of cutting quality, leather tilting, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

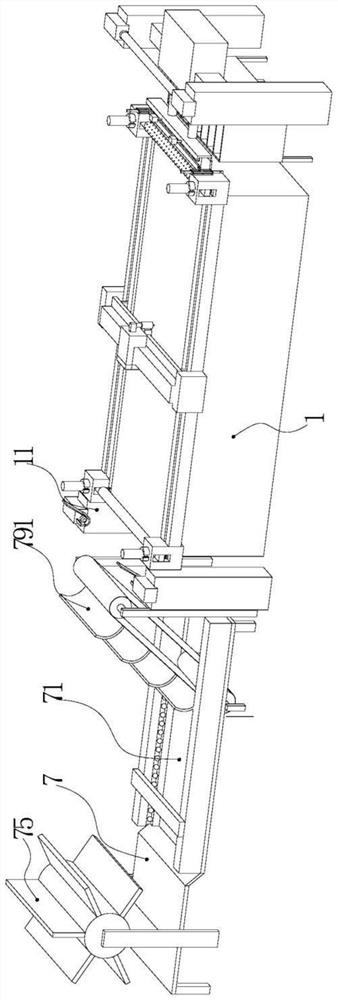

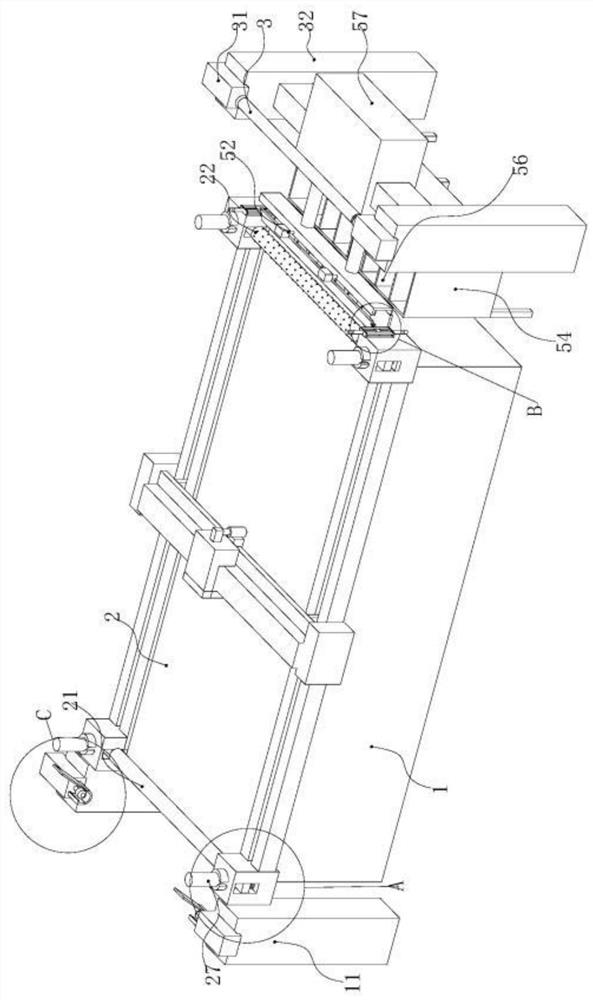

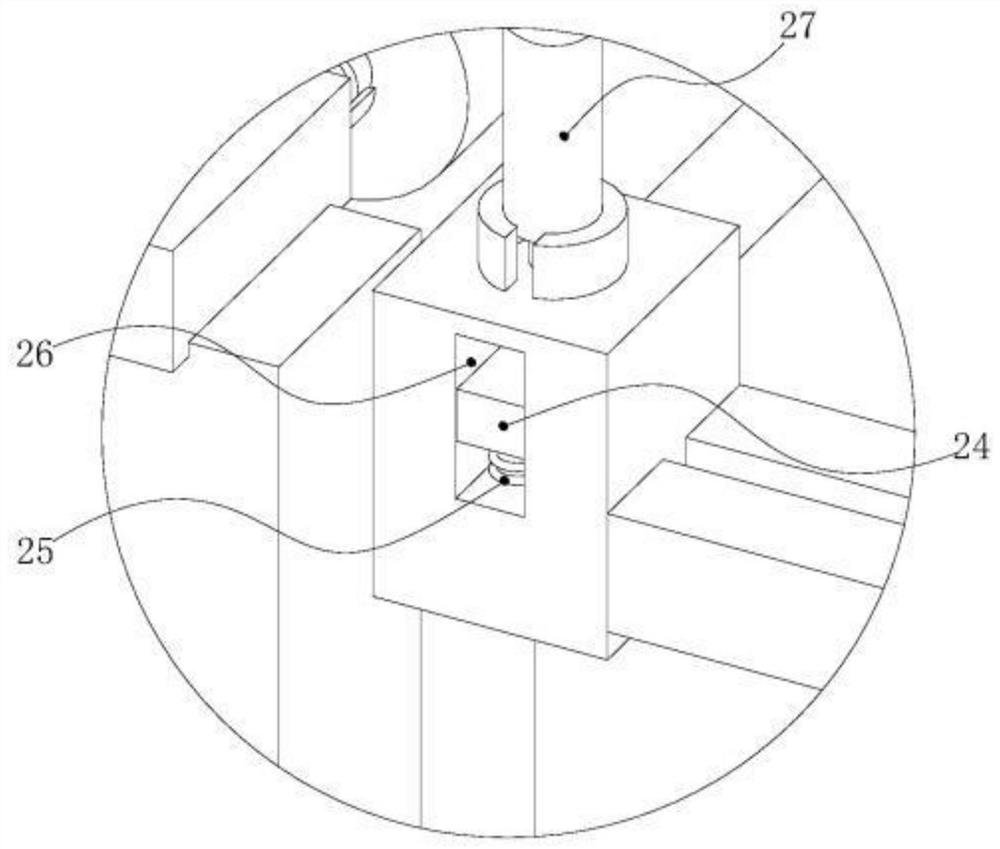

[0023] Such as Figure 1-10 As shown, a leather automatic cutting system includes a cutting table 1, a feeding device, a leather fixing device, a cutting device and a storage device, and the feeding device includes a first conveying mechanism, a feeding mechanism, a guiding mechanism and a fixing mechanism , the first conveying mechanism includes a material storage plate 7, a conveying plate 71, a first partition plate 72, a limit plate 73, a rotating roller 74, a paddle 75, a rotating roller driving member, a first installation groove 77 and a ball 78, The material storage plate 7 is used to place the raw material roll, and the conveying plate 71 is fixed on one side of the material storing plate 7 for rolling the raw material roll, and the first separator 72 is symmetrically fixed on both sides of the conveying plate 71 to prevent the raw material from The rollers fall during the rolling process; the limiting plate 73 is fixed on the first partition 72 to ensure that the raw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com