Preparation method for arc thread anchor bolt assembly for wind turbine

A wind turbine and arc technology, which is applied in the field of wind turbine tower bolt connection and anchor bolt connection, can solve the problems of affecting the installation and use of normal threaded connection pairs, difficult to find in time for manual maintenance and maintenance, and high surface hardness of anchor bolts. Achieve the effect of reducing the difficulty of rolling processing, saving raw materials, and high material utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

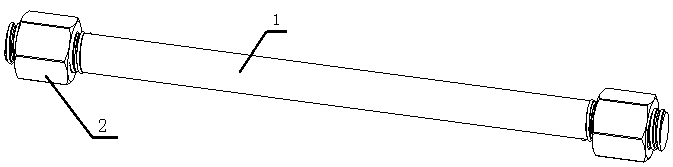

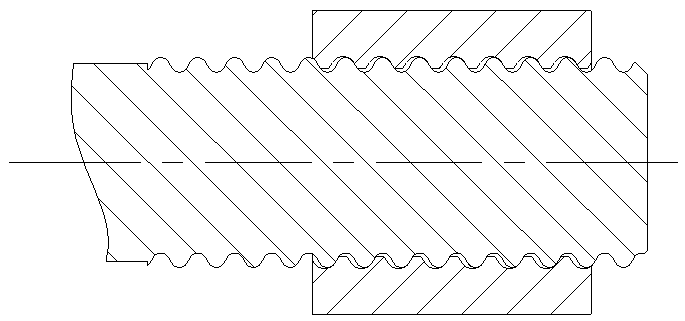

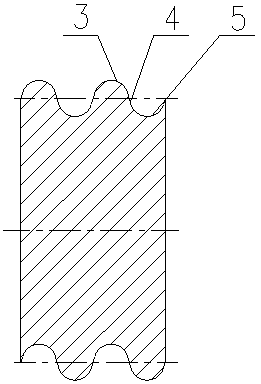

[0048] A method for preparing a circular-arc threaded anchor bolt assembly for a wind power generating set. The circular-arc threaded anchor bolt assembly includes an anchor bolt 1 and a nut 2, and the anchor bolt 1 and the nut 2 are provided with internal and external circular-arc threads that cooperate with each other.

[0049] The preparation method of anchor bolt 1 comprises the following steps:

[0050] 11) Select the round steel bar and roll the corresponding length according to the required length or double length as the billet;

[0051] 12) Use the straightening machine to straighten the blank, and chamfer both ends;

[0052] 13) Use a flaw detector to conduct ultrasonic + magnetic flux leakage combined flaw detection on the blank;

[0053] 14) Heat treatment of the blank;

[0054] 15) Straighten the blank and remove the surface scale;

[0055] 16) Use a flaw detector to conduct eddy current or magnetic particle flaw detection on the billet;

[0056] 17) Roll arc t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Distance | aaaaa | aaaaa |

| Distance | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com