Purification technology with membrane separation strengthening function for hydrogen in high-hydrogen-content refinery gas through pressure swing adsorption

A technology of pressure swing adsorption and hydrogen refinery, which is applied in hydrogen separation, hydrogen/synthesis gas production, hydrogen separation using solid contact, etc. It can solve problems such as increased operation and maintenance costs of adsorption devices, difficulties in regeneration and desorption, and failure of adsorbents , to achieve the effect of reducing the cost of hydrogen separation and purification, improving regeneration and desorption conditions, and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

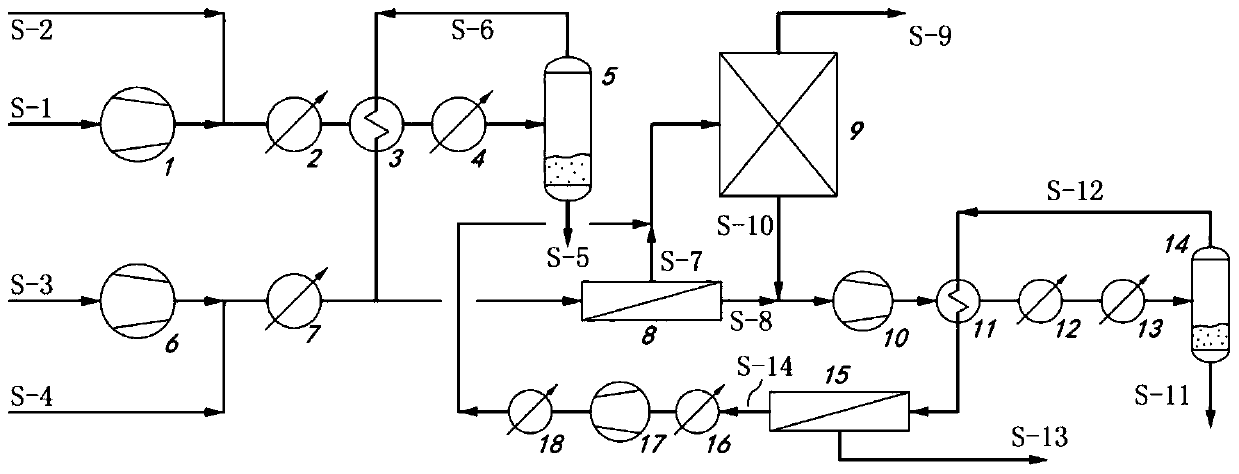

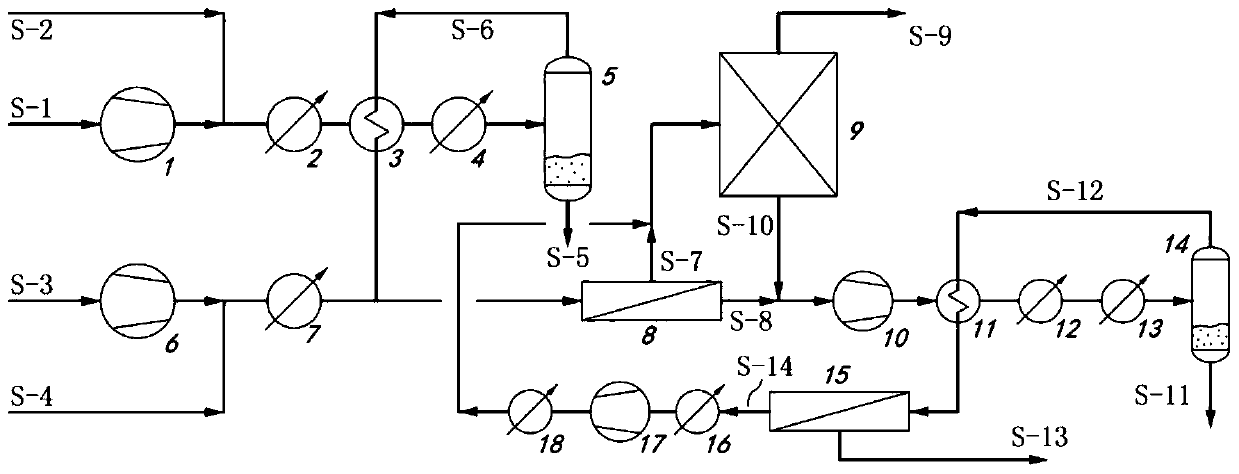

[0026] Example 1 For the high-hydrogen-containing tail gas by-product of a 2.2 million-ton continuous catalytic reforming unit in a refining and chemical enterprise, the membrane separation-enhanced pressure swing adsorption process of the present invention is used to purify hydrogen. According to the composition and pressure, catalytic reforming high hydrogen content tail gas belongs to the second high hydrogen content refinery gas S-2.

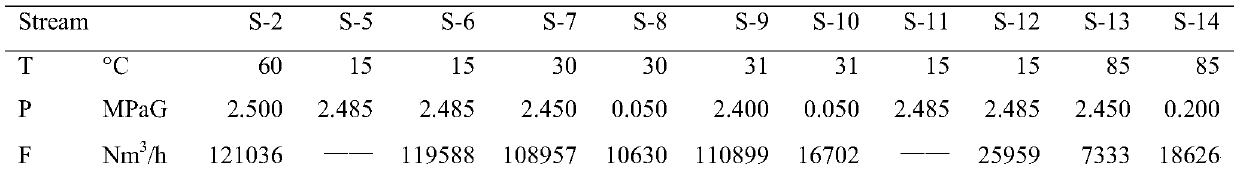

[0027] Table 1 is a list of the composition and operating parameters of key materials in Example 1.

[0028]

[0029]

[0030] Such as figure 1As shown, the high-hydrogen-containing tail gas produced by the catalytic reforming unit passes through the first cooler 2, the first heat exchanger 3, and the second cooler 4 in sequence, and then enters the first liquid separation tank 5, and the second liquid is extracted at the bottom of the tank. A condensate S-5, the first non-condensable gas S-6 is produced at the top of the tank, and en...

Embodiment 2

[0033] Example 2 Aiming at the high-hydrogen-containing tail gas by-product of 600,000 tons of continuous catalytic reforming unit of a refining and chemical enterprise, and the low fraction gas and dry gas of 1.2 million tons of hydrocracking unit, the membrane separation intensified variant of the present invention is adopted. Hydrogen purification by pressure adsorption process. According to the composition and pressure, catalytic reforming high-hydrogen-containing tail gas belongs to the second high-hydrogen-containing refinery gas S-2, and the low fraction gas and dry gas of the hydrocracking unit belong to the first high-hydrogen-containing refinery gas S-1.

[0034] The composition of key material and operating parameter list in the embodiment 2 of table 2.

[0035]

[0036] Such as figure 1 As shown, the low fraction gas and dry gas of the hydrocracking unit are pressurized to 2.5MPaG by the first compressor 1, and then combined with the high hydrogen-containing ta...

Embodiment 3

[0039] Example 3 For the high-fraction gas, low-fraction gas and dry gas of a 2 million-ton diesel hydrocracking unit in a refining and chemical enterprise, the membrane separation-enhanced pressure swing adsorption process of the present invention is used to purify hydrogen. According to the composition and pressure, the diesel hydrocracking high-fraction gas belongs to the fourth highest hydrogen-containing refinery gas S-4, and the diesel hydrocracking low-fraction gas and dry gas belongs to the first high hydrogen-containing refinery gas S-1.

[0040] Table 3 is a list of composition and operating parameters of key materials in Example 3.

[0041]

[0042] Such as figure 1 As shown, the low fraction gas and dry gas of the hydrocracking unit are pressurized to 2.5MPaG by the first compressor 1, then pass through the first cooler 2, the first heat exchanger 3, and the second cooler 4, and then enter The first liquid separation tank 5 produces the first condensate S-5 at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com