Modular sludge thermal hydrolysis treatment method and device

A treatment device and treatment method technology, which is applied in the direction of pyrolysis treatment of sludge, etc., can solve the problems of non-standardized treatment of sludge, threats to the ecological environment, insufficient disposal capacity, etc., and achieve the reduction of odor concentration, energy consumption and cost Effects of reduction, processing efficiency improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

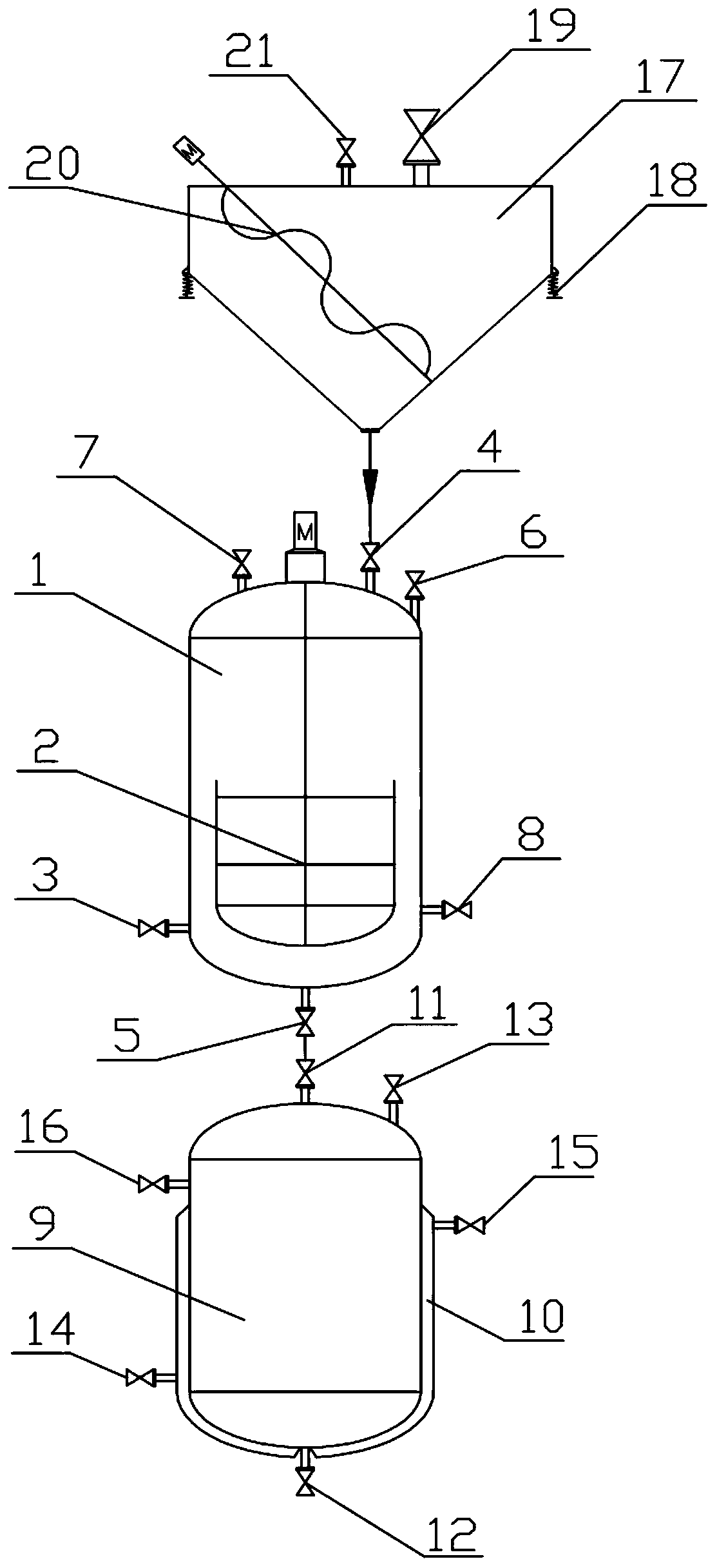

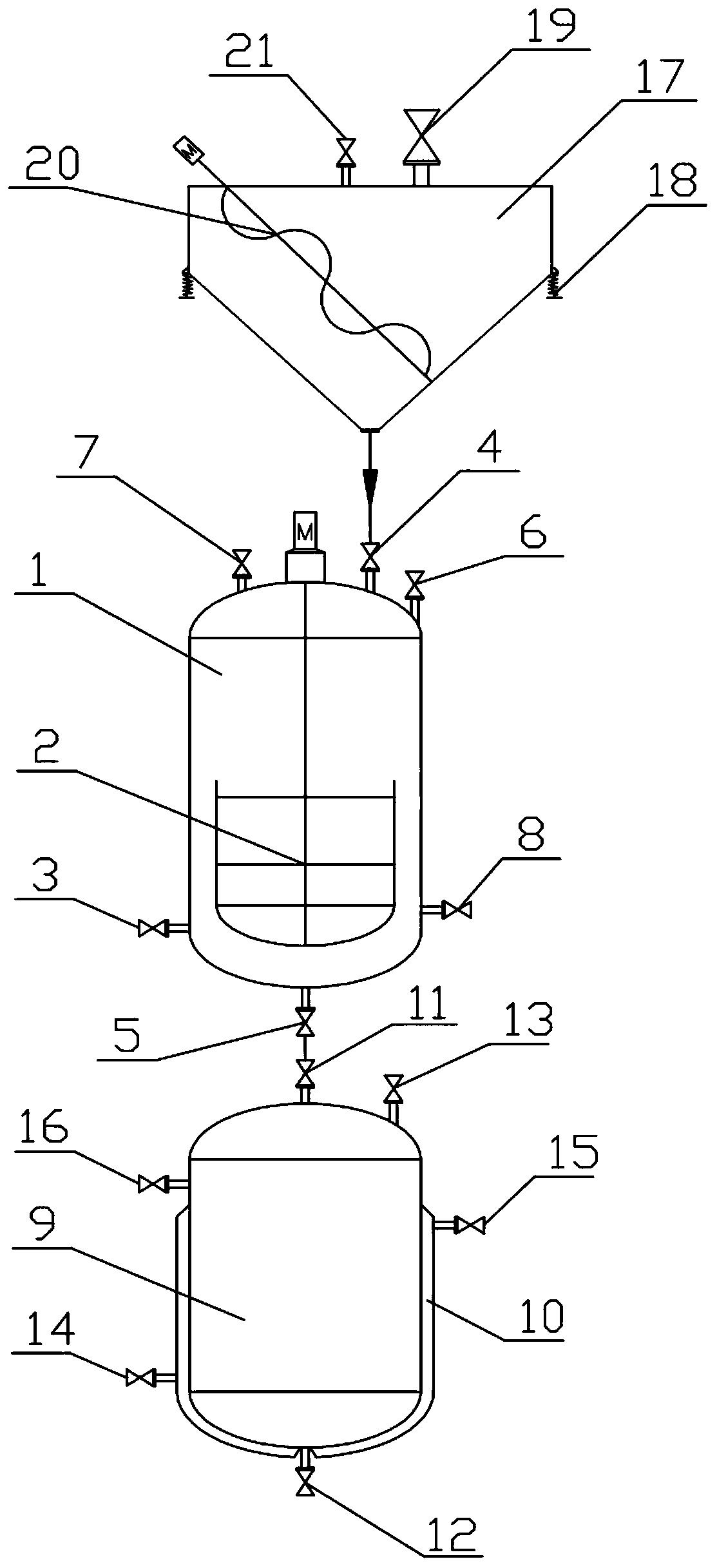

[0022] like figure 1 As shown, the present invention discloses a sludge thermal hydrolysis treatment device, comprising a thermal hydrolysis reactor 1, a cooling jacket tank, a metering bin 17, the metering bin 17, the thermal hydrolysis reactor 1, the The above-mentioned cooling jacket tanks are connected in sequence.

[0023] The thermal hydrolysis reactor 1 is provided with a stirring device 2, and the thermal hydrolysis reactor 1 is provided with a steam inlet valve 3, a sludge feed valve 4, a mud discharge valve 5, and a pressure relief exhaust valve. 6. Pressure transmission valve 7, temperature control transmission valve 8, the sludge feed valve 4 is connected to the metering bin 17, and the mud discharge valve 5 is connected to the cooling jacket tank.

[0024] The cooling jacket tank includes a buffer tank 9 and a cooling jacket 10, the cooling jacket 10 is installed outside the buffer tank 9, and the buffer tank 9 is provided with a pyrolysis mud feed valve 11, a co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com