Concrete for maritime works and application thereof

A technology of marine concrete and cementitious materials, applied in the field of building materials, can solve problems such as chemical corrosion and erosion, and achieve the effects of good crack resistance, good carbonation resistance, and excellent chemical corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

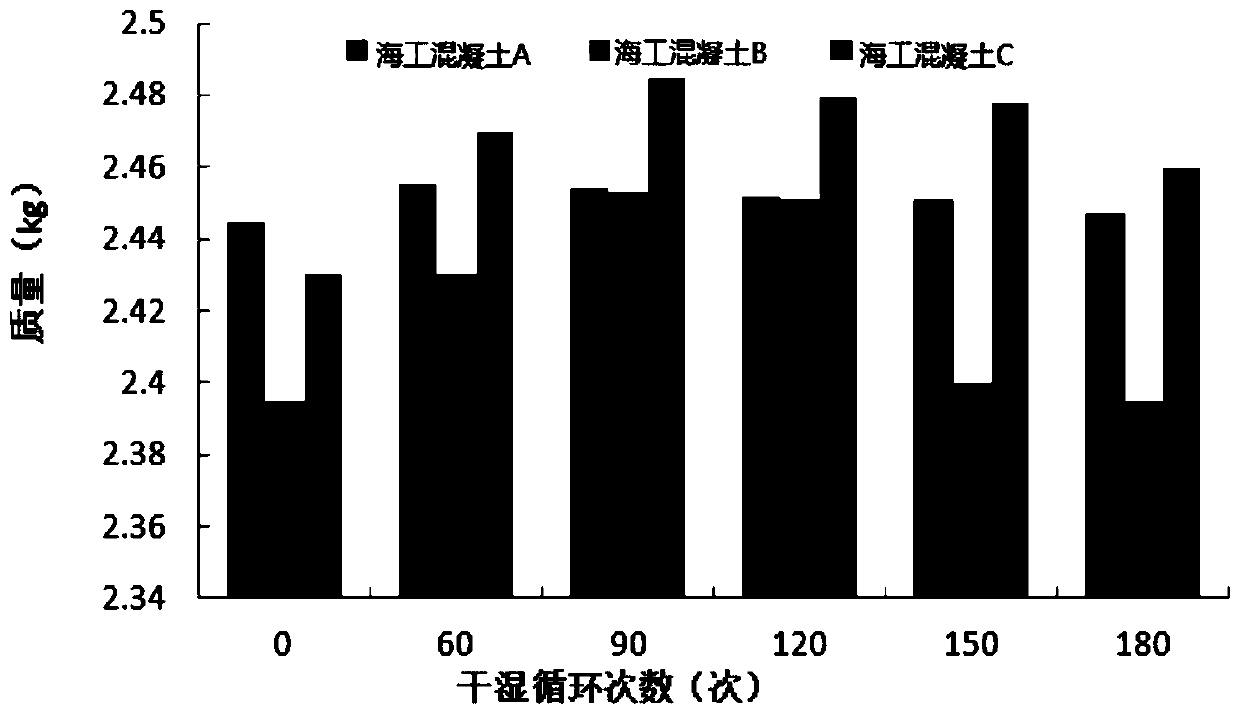

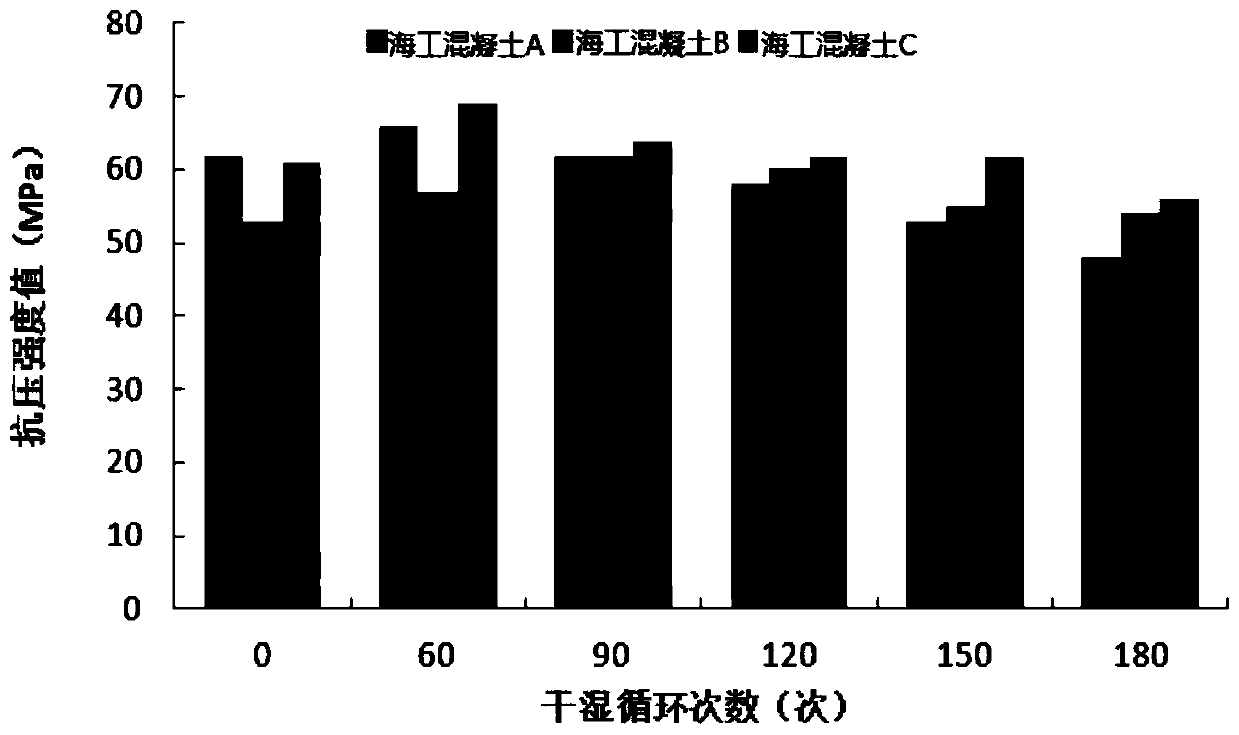

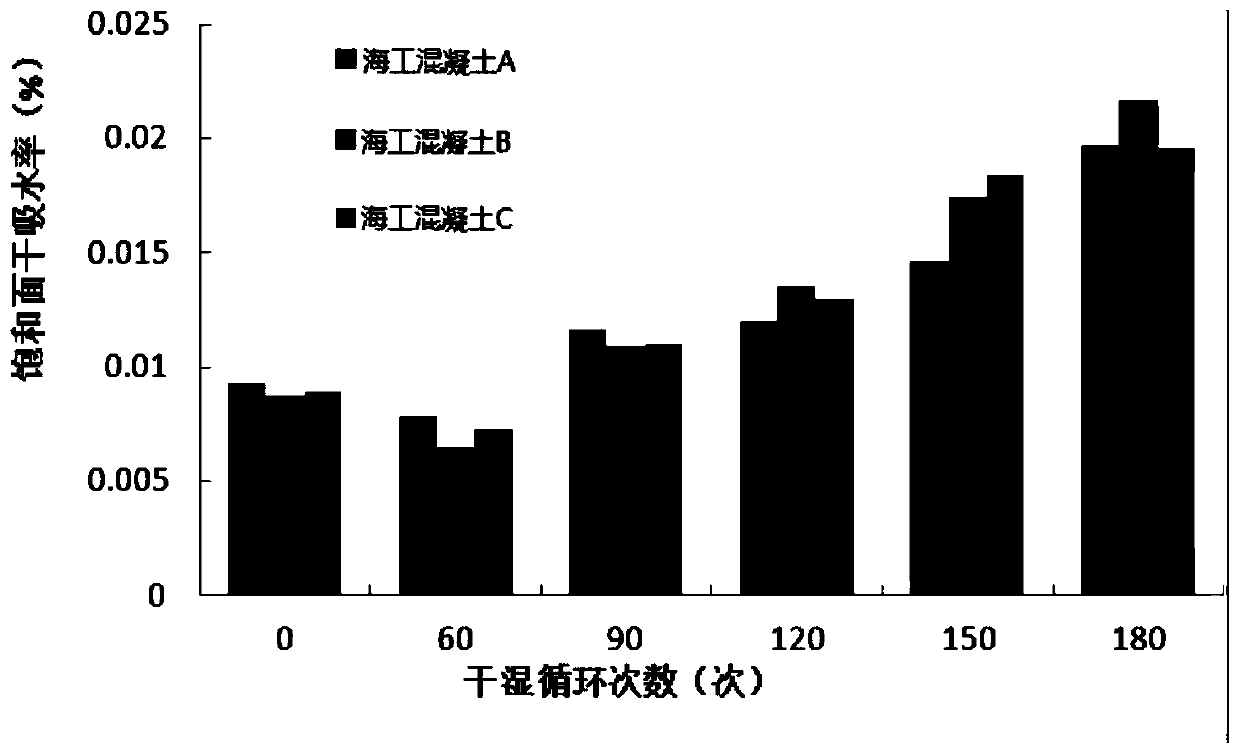

Embodiment 1

[0043] The application provides a marine concrete, which includes: machine-made sand, gravel, cementitious material, admixture and water. Wherein, the sand rate of marine concrete is 41%-45%, and the cementitious material includes cement and mineral admixture, and the mineral admixture accounts for 60-80% of the total cementitious material, and the admixture The dosage is 1.0-1.5%, and the water-binder ratio of the marine concrete is less than 0.4.

[0044] In the marine concrete of Example 1, the amount of cementitious material is 411kg / m 3 . The use of machine-made sand accounts for 43% of marine concrete, that is, the sand rate is 43%. The maximum particle size of the crushed stones used is 25 mm, and in some implementation manners, crushed stones continuously graded from 5 mm to 25 mm may also be used. The dosage of the admixture is 1.0%. The admixture can be selected from polycarboxylate high-performance water reducing agent, and the water reducing rate of the admixtur...

Embodiment 2

[0052] The application provides a marine concrete, which includes: machine-made sand, gravel, cementitious material, admixture and water. Wherein, the sand rate of marine concrete is 41%-45%, and the cementitious material includes cement and mineral admixture, and the mineral admixture accounts for 60-80% of the total cementitious material, and the admixture The dosage is 1.0-1.5%, and the water-binder ratio of the marine concrete is less than 0.4.

[0053] In Example 2, the marine concrete includes machine-made sand 136kg / m 3 , gravel 1022kg / m 3 , cementitious material 390kg / m 3 , admixture 3.9kg / m 3 and water 152kg / m 3 . Cementitious materials include: cement 118kg / m 3 , fly ash 136kg / m 3 , mineral powder 136kg / m 3 . The water-binder ratio of the above-mentioned marine concrete is 0.39.

[0054] The maximum particle size of the gravel is 25mm, and the sand rate is about 45%. The sand rate refers to the percentage of the mass of the machine-made sand to the total ma...

Embodiment 3

[0058] The application provides a marine concrete, which includes: machine-made sand, gravel, cementitious material, admixture and water. Wherein, the sand rate of marine concrete is 41%-45%, and the cementitious material includes cement and mineral admixture, and the mineral admixture accounts for 60-80% of the total cementitious material, and the admixture The dosage is 1.0-1.5%, and the water-binder ratio of the marine concrete is less than 0.4.

[0059] In Example 3, the marine concrete includes machine-made sand 790kg / m 3 , gravel 1047kg / m 3 , cementitious material 411kg / m 3 , admixture 4.11kg / m 3 and water 152kg / m 3 . Cementitious materials include: cement 123kg / m 3 , fly ash 144kg / m 3 , mineral powder 144kg / m 3 . The water-binder ratio of the above-mentioned marine concrete is 0.37.

[0060] The gravel adopts 5mm-25mm continuous graded gravel, and the sand rate is about 43%. The sand rate refers to the percentage of the mass of machine-made sand in the total m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Apparent density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com