Standard ultrasonic power source

An ultrasonic power, standard technology, applied in the measurement of ultrasonic/sonic/infrasonic waves, measuring devices, instruments, etc., can solve the problems of low output frequency, poor anti-oxidation and anti-corrosion performance, and easy detachment of piezoelectric chips

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

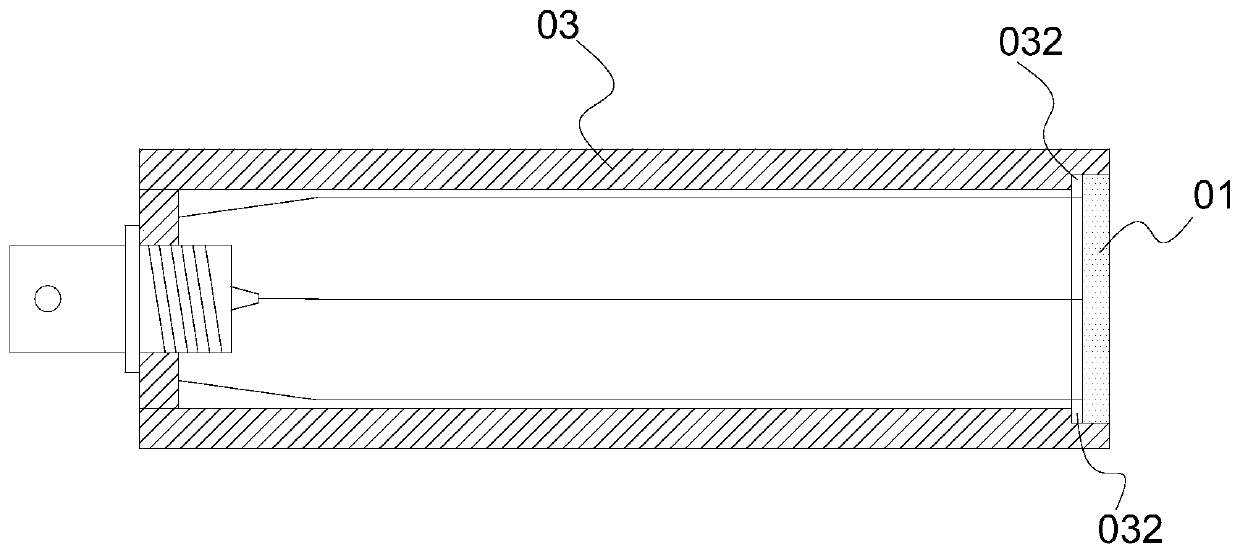

[0062] The present invention will be described in further detail below in conjunction with the accompanying drawings.

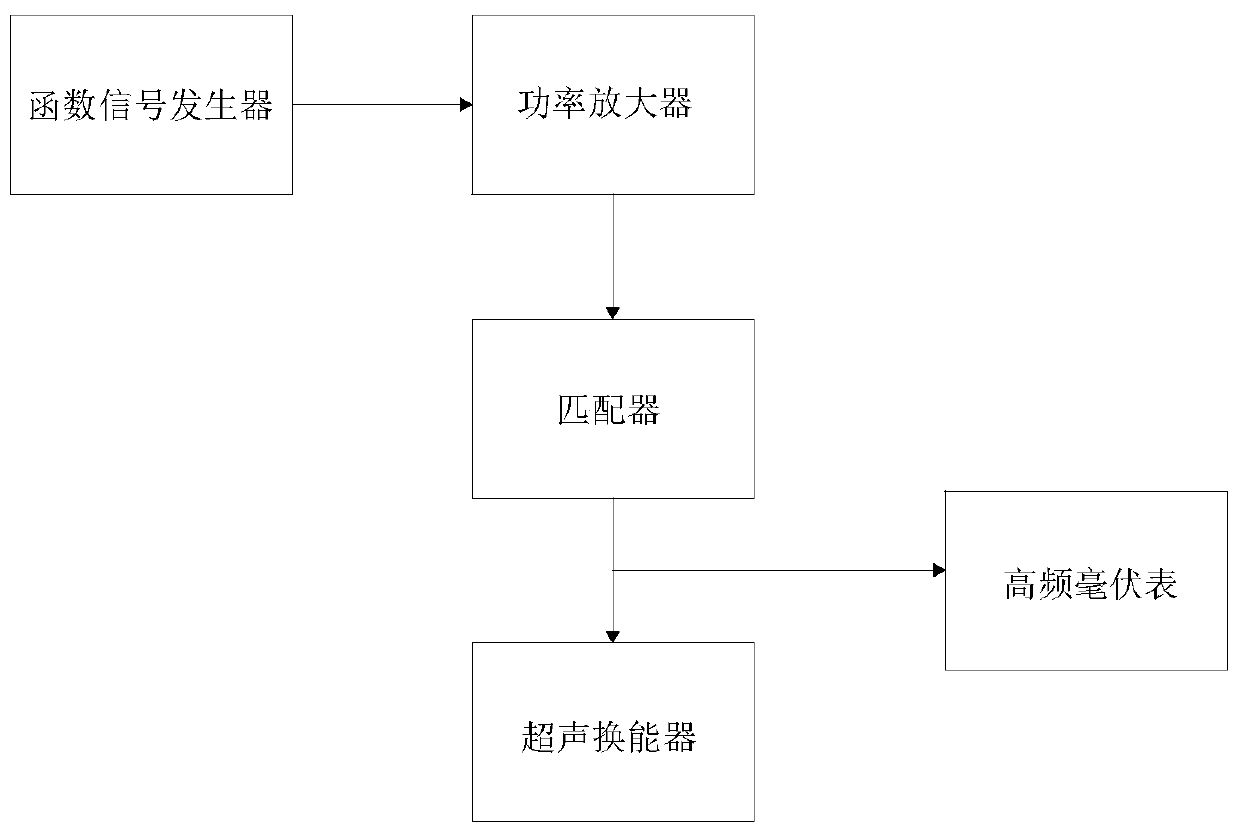

[0063] Figure 4A standard ultrasound power source according to one embodiment of the invention is schematically shown. As shown in the figure, the standard ultrasonic power source includes a housing, an input device and a display device fixed on the housing, and a DDS signal generation module, a control module, a power amplification module and an ultrasonic transducer fixed in the housing. Compared with the standard ultrasonic power source system using independent instruments in the prior art, the various components of the present invention are integrated into a housing to form a complete machine, which can be carried to the site for calibration.

[0064] The input device is used to input frequency and power parameters, specifically, a keypad or a touch screen can be used.

[0065] The display device is used to display information such as input frequency a...

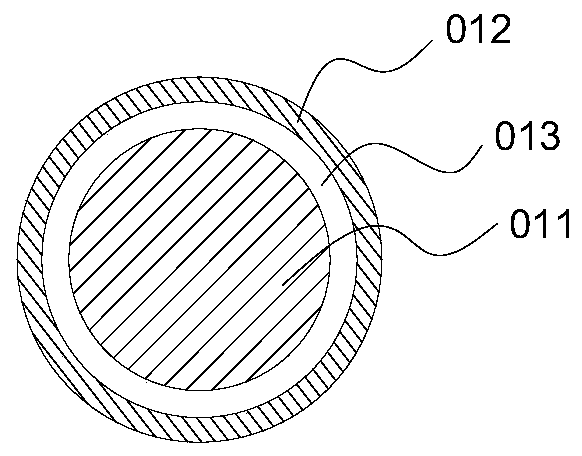

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| Inner diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com