Method for measuring modified acrylic and acrylic blended fabric fiber contents

A blended fabric and modified acrylic fiber technology, which is applied in the direction of weighing by removing certain components, can solve the problem of chemically dissolving quantitatively modified acrylic and acrylic blends, modified acrylic cannot be completely dissolved, and the distillation rate is not good Control and other problems, to achieve the effect of fast and convenient determination method, accelerated dissolution speed and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

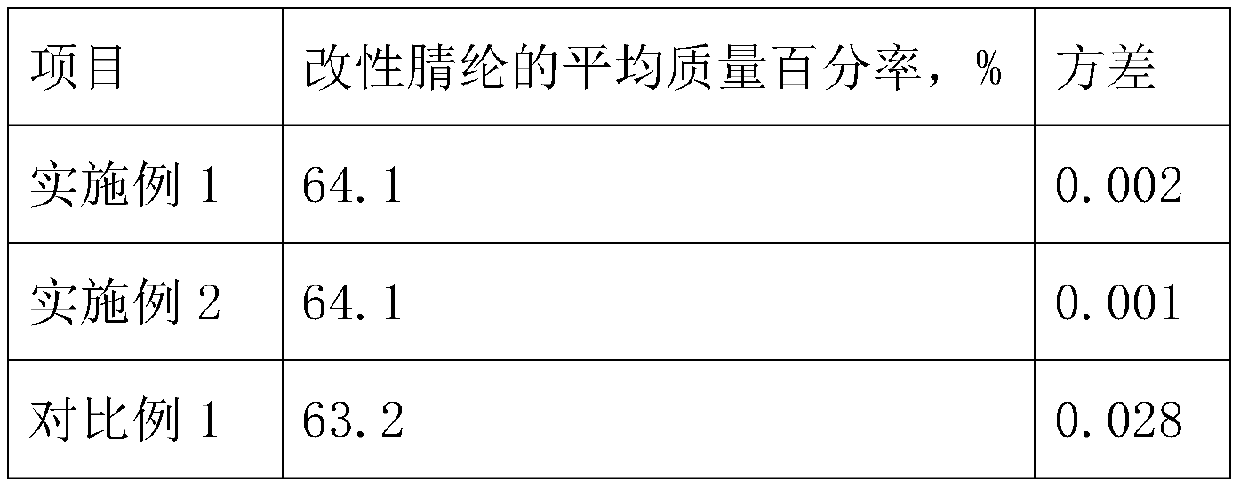

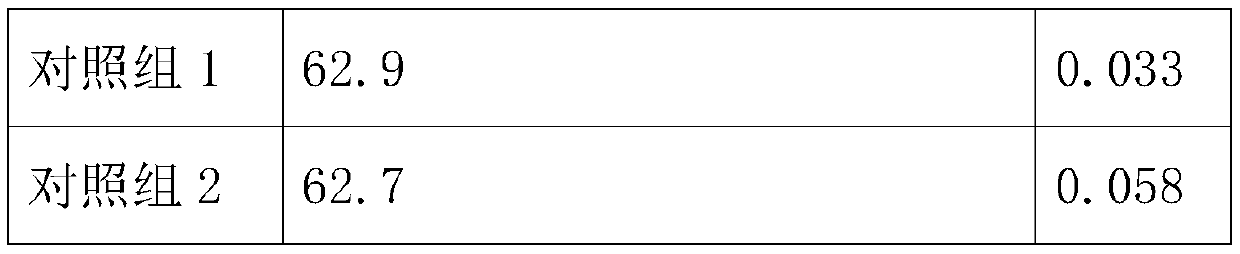

Examples

Embodiment 1

[0021] A method for measuring the fiber content of a modified acrylic fiber and acrylic fiber blended fabric, including the following steps:

[0022] (1) Take all the samples and disassemble them into yarn shapes, put them in a weighing bottle, dry, cool and weigh to obtain the dry mass of the sample m 0 ;

[0023] (2) Put the weighed sample into a Erlenmeyer flask, add 100mL solution for each gram of sample, put a glass stopper, shake the flask to fully wet the sample, then put the flask into a constant temperature shaking water bath at 85℃ In the pot, continue to vigorously shake for 1 hour, in which the dissolving liquid is made of the following components by weight: 85 parts by weight of cyclohexanone, 1 part of 3-cyclohexylaminopropanesulfonic acid, and 0.8 parts of cyclohexanone oxime;

[0024] (3) Pour the dissolved sample into a glass sand core crucible, drain the liquid by vacuum suction, clean the residue in the crucible with absolute ethanol 2 times, and then clean it with...

Embodiment 2

[0030] A method for measuring the fiber content of a modified acrylic fiber and acrylic fiber blended fabric, including the following steps:

[0031] (1) Take all the samples and disassemble them into yarn shapes, put them in a weighing bottle, dry, cool and weigh to obtain the dry mass of the sample m 0 ;

[0032] (2) Put the weighed sample into an Erlenmeyer flask, add 120mL of dissolving solution per gram of sample, plug the glass stopper, shake the flask to fully wet the sample, then place the flask in a 95℃ constant temperature shaking water bath In the pot, continue to vigorously shake for 1 hour, in which the dissolving liquid is made of the following components by weight: 90 parts of cyclohexanone, 3 parts of 3-cyclohexylaminopropanesulfonic acid, and 1.2 parts of cyclohexanone oxime;

[0033] (3) Pour the dissolved sample into a glass sand core crucible, vacuum and drain the liquid, clean the residue in the crucible with absolute ethanol 3 times, and then clean it with tap w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com