Treatment method for printed circuit board sewage

A printed circuit board and treatment method technology, applied in water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. problems, to achieve the effect of reducing solid particle content, reducing chemical oxygen demand, and reducing sludge compaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

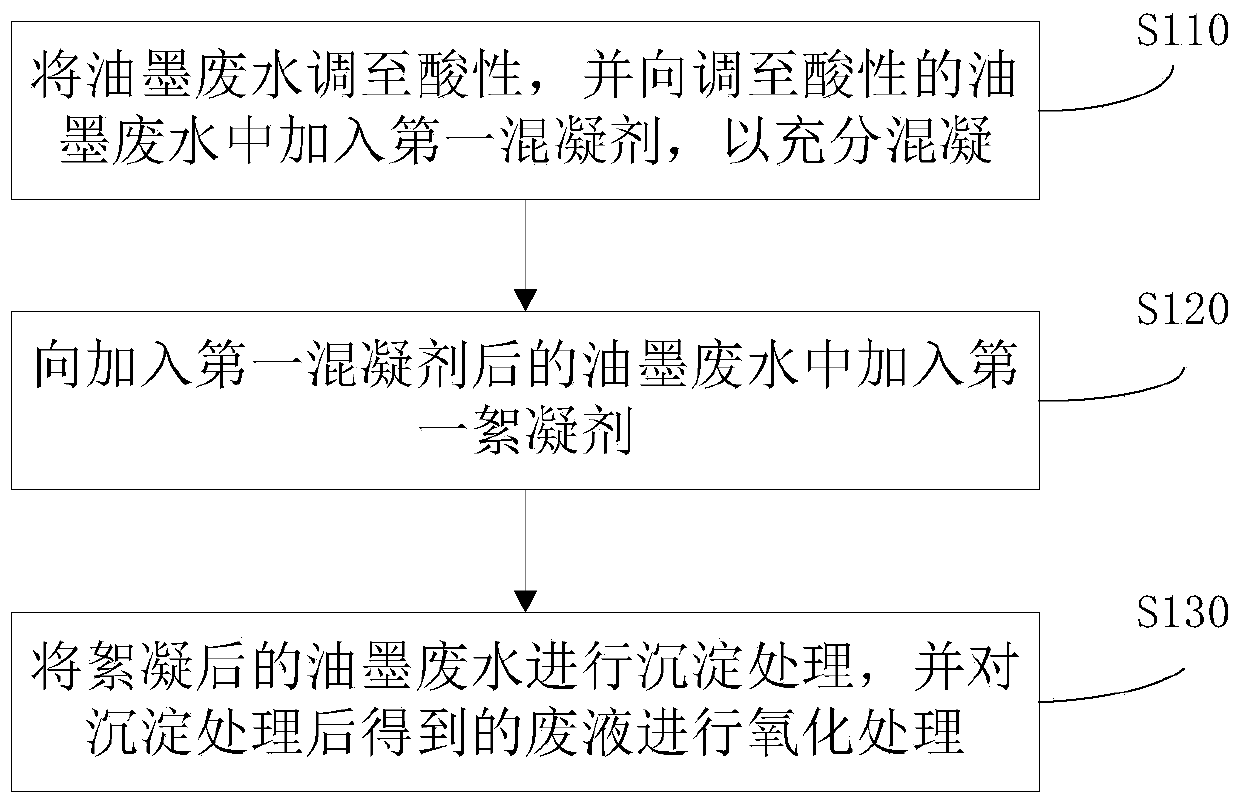

Method used

Image

Examples

Embodiment 1

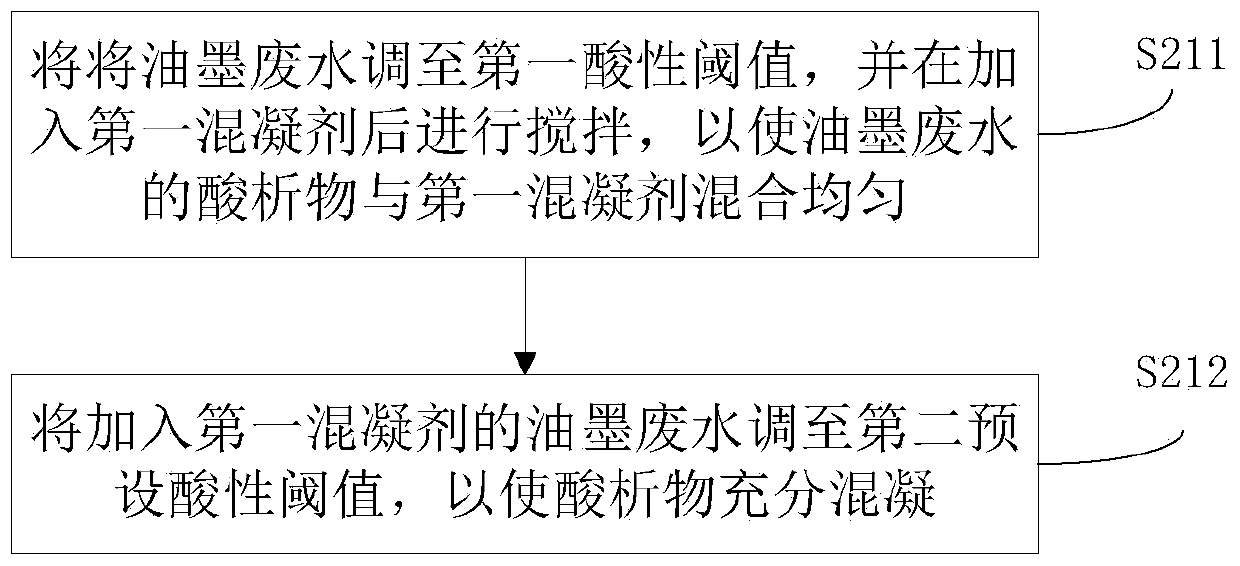

[0067] Adjust the pH of the ink wastewater to 2.5, and put the coagulant polyferric sulfate into the concentration of 0.16mg / L, and the stirring speed is 150 rpm; after 20 minutes of reaction, adjust the pH of the ink wastewater to 4, and after 20 minutes of reaction, follow Add flocculant polyacrylamide at a concentration of 5mg / L, and transfer the ink wastewater to a treatment load of 1m 3 / (m 2 h) Sedimentation tank.

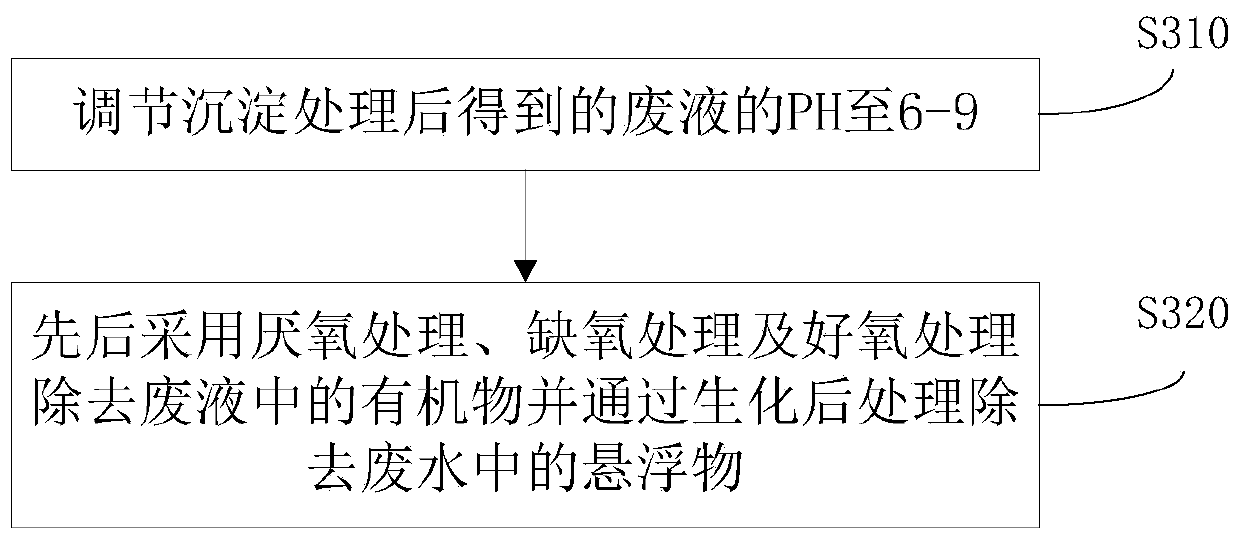

[0068]Put 6g / L ferrous sulfate and 2.5g / L hydrogen peroxide into the effluent of the sedimentation tank for oxidation treatment, and transfer the effluent of the oxidation treatment and the liquid obtained after press filtration of the sludge in the sedimentation tank to the organic wastewater regulating tank for treatment. The effluent of the organic wastewater adjustment tank is adjusted to a pH of 7, and then anaerobic treatment, anoxic treatment, and good-care treatment are performed, and the waste water after the good-care treatment is subjected to the ...

Embodiment 2

[0070] Adjust the pH of the ink wastewater to 2.8, and put in the coagulant polymerized ferric sulfate at a concentration of 0.15 mg / L, and the stirring speed is 150 rpm; after 15 minutes of reaction, adjust the pH of the ink wastewater to 4.5, and after 20 minutes of reaction according to Add flocculant polyacrylamide at a concentration of 5mg / L, and transfer the ink wastewater to a treatment load of 1m 3 / (m 2 h) Sedimentation tank.

[0071] Put 4g / L ferrous sulfate and 2g / L hydrogen peroxide into the effluent of the sedimentation tank for oxidation treatment, and transfer the effluent of the oxidation treatment and the liquid obtained after press filtration of the sludge in the sedimentation tank to the organic wastewater regulating tank for treatment. The effluent of the organic wastewater regulating tank is adjusted to a pH of 6, and then anaerobic treatment, anoxic treatment and good-care treatment are performed, and the waste water after the good-care treatment is subj...

Embodiment 3

[0073] Adjust the pH of the ink wastewater to 2.6, and put in the coagulant polymerized ferric sulfate at a concentration of 0.17 mg / L, and the stirring speed is 150 rpm; after 30 minutes of reaction, adjust the pH of the ink wastewater to 4.1, and react for 25 minutes. Add flocculant polyacrylamide at a concentration of 5mg / L, and transfer the ink wastewater to a treatment load of 1m 3 / (m 2 h) Sedimentation tank.

[0074] Put 8g / L ferrous sulfate and 3g / L hydrogen peroxide into the effluent of the sedimentation tank for oxidation treatment, and transfer the effluent of the oxidation treatment and the liquid obtained after press filtration of the sludge in the sedimentation tank to the organic wastewater regulating tank for treatment. The effluent of the organic wastewater adjustment tank is adjusted to a pH of 8, and then anaerobic treatment, anoxic treatment, and good-care treatment are performed, and the waste water after the good-care treatment is subjected to the first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com