A kind of preparation method of degradable aliphatic copolyester

A technology for degrading fat and copolyester, which is applied in the field of preparation of degradable aliphatic copolyester, can solve the problem that the synthesis and performance research of aliphatic copolyester is very small, it is difficult to form multi-block copolymers, and it is difficult to form high molecular weight polymer. Ester and other problems, to achieve the effect of large application value, low cost, and no need for post-treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

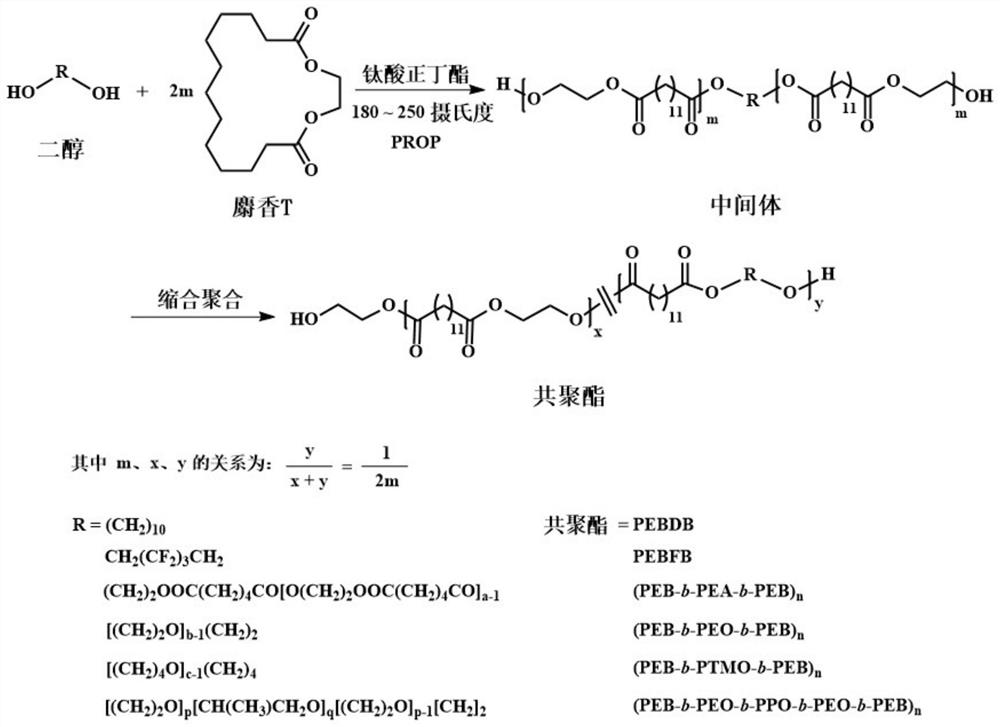

[0040] Example 1 Degradable aliphatic copolyester (PEBDB) produced by in-situ ring-opening-condensation cascade polymerization by mixing decanediol and musk T

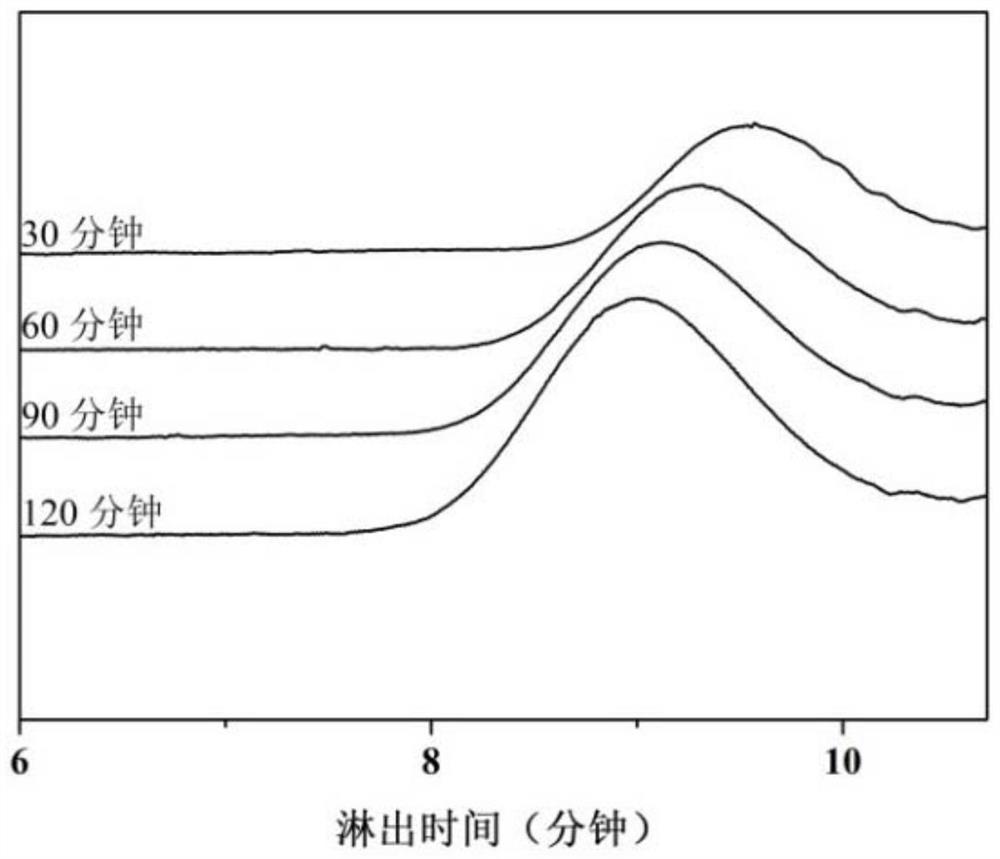

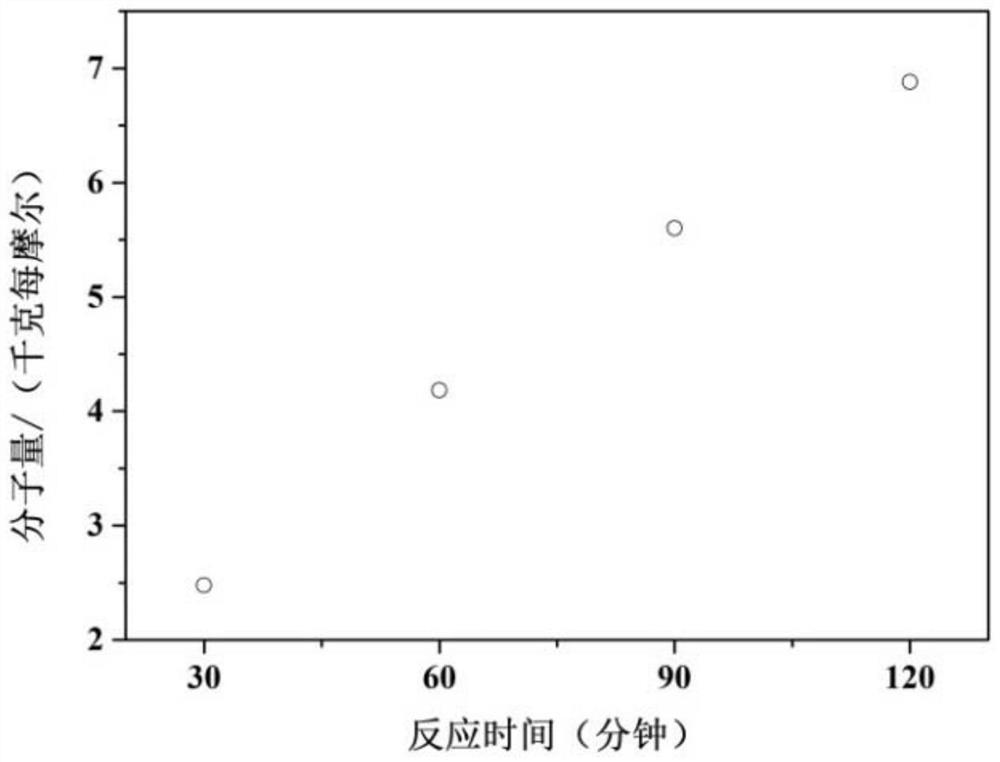

[0041] Add decanediol (0.05 g) and musk T (5.00 g) into a 100 ml three-necked flask, pass nitrogen gas to remove oxygen, place the three-necked flask in a salt bath and heat to 200 degrees Celsius, and mechanically stir, then add Slowly add 10.1 microliters of n-butyl titanate to the sample vessel, and perform in-situ ring-opening-condensation cascade polymerization reaction under nitrogen atmosphere to generate corresponding polymers. Samples were taken every 30 minutes during the reaction, and the reaction was stopped after 120 minutes.

[0042] The size exclusion chromatogram and the molecular weight of the copolyester change with time are shown in figure 2 , image 3 , demonstrating the successful synthesis of the target product, whose molecular weight can be controlled by controlling the polymerization time. I...

Embodiment 2

[0043] Example 2 Degradable aliphatic copolyester (PEBDB) produced by in-situ ring-opening-condensation cascade polymerization by mixing decanediol and musk T

[0044] Add decanediol (0.50 g) and musk T (5.00 g) into a 100 ml three-necked flask, pass nitrogen gas to remove oxygen, place the three-necked flask in a salt bath and heat to 240 degrees Celsius, and mechanically stir, followed by micro-injection 11.0 microliters of n-butyl titanate was slowly added to the sample vessel, and in-situ ring-opening-condensation cascade polymerization was carried out under a nitrogen atmosphere to generate corresponding polymers. Samples were taken every 30 minutes during the reaction, and the reaction was stopped after 120 minutes.

[0045] Molecular weight of copolyester with time Figure 4 , demonstrating the successful synthesis of the target product, whose molecular weight can be controlled by controlling the polymerization time. It can be calculated that the mass content of funct...

Embodiment 3

[0046] Example 3 In situ ring-opening-condensation cascade polymerization by mixing decanediol and musk T to generate degradable aliphatic copolyester (PEBDB)

[0047] Add decanediol (3.00 g) and musk T (10.0 g) into a 100 ml one-necked flask, and slowly add 26.0 μl of n-butyl titanate through a microsampler. The single-necked flask was placed in a salt bath and heated to 200 degrees Celsius, and mechanically stirred, reacted for 10 minutes under nitrogen atmosphere, and then vacuumed and polymerized for 30 minutes to finally generate the corresponding polymer.

[0048] For size exclusion chromatograms see Figure 5 , the measured molecular weight was 20.3 kg per mole, proving the successful synthesis of the target product. It can be calculated that the mass content of functional groups in the copolyester is about 23%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com