Method for allowing shield to pass through river-near air shaft

A wind shaft and shield technology, which is applied in shaft lining, shaft equipment, earthwork drilling and mining, etc., can solve the problems that the bracket cannot meet the construction requirements, the construction period is long, and the safety risk is high, and it is not easy to deform, improve the support strength, Ease of installation and positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

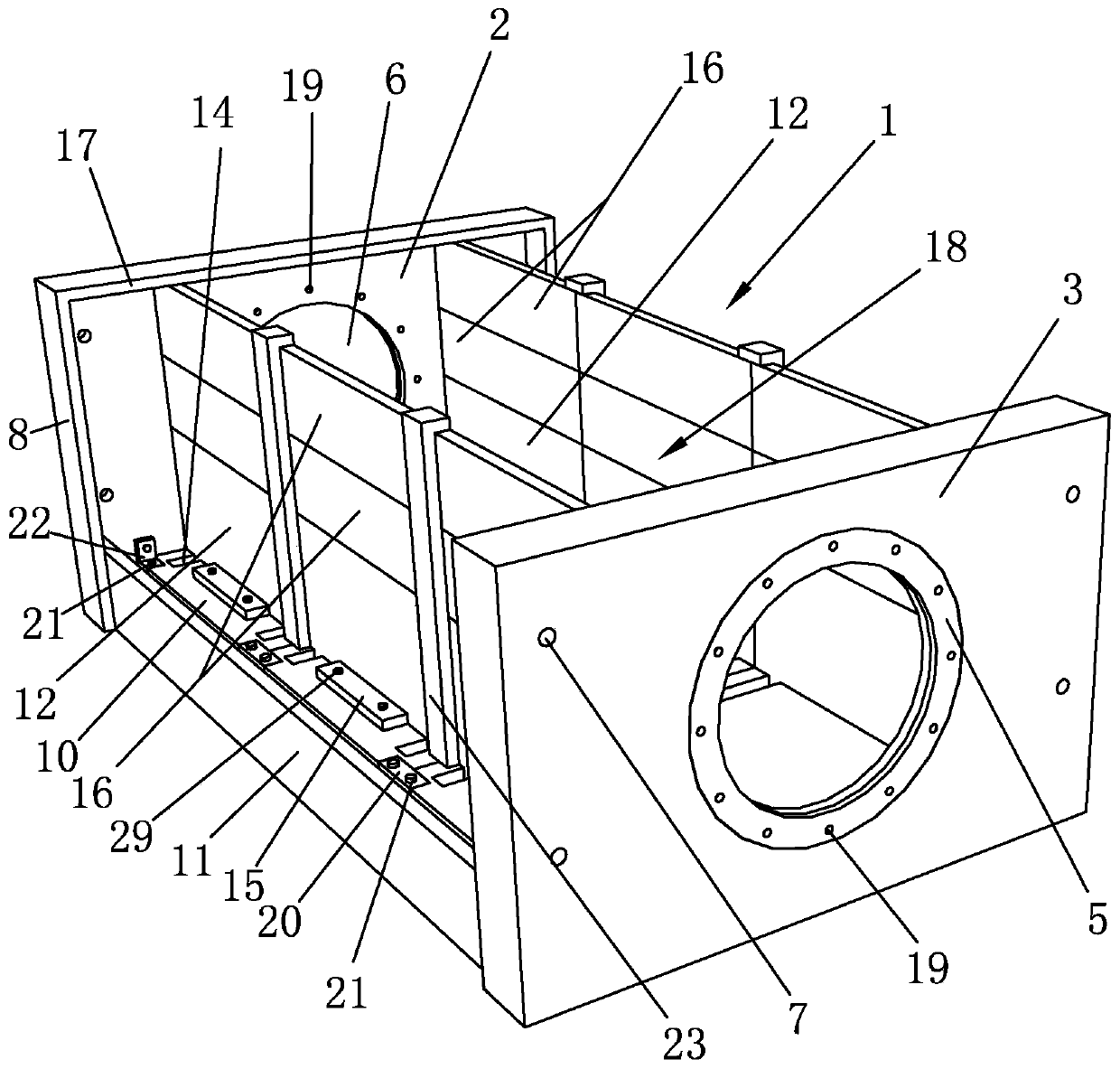

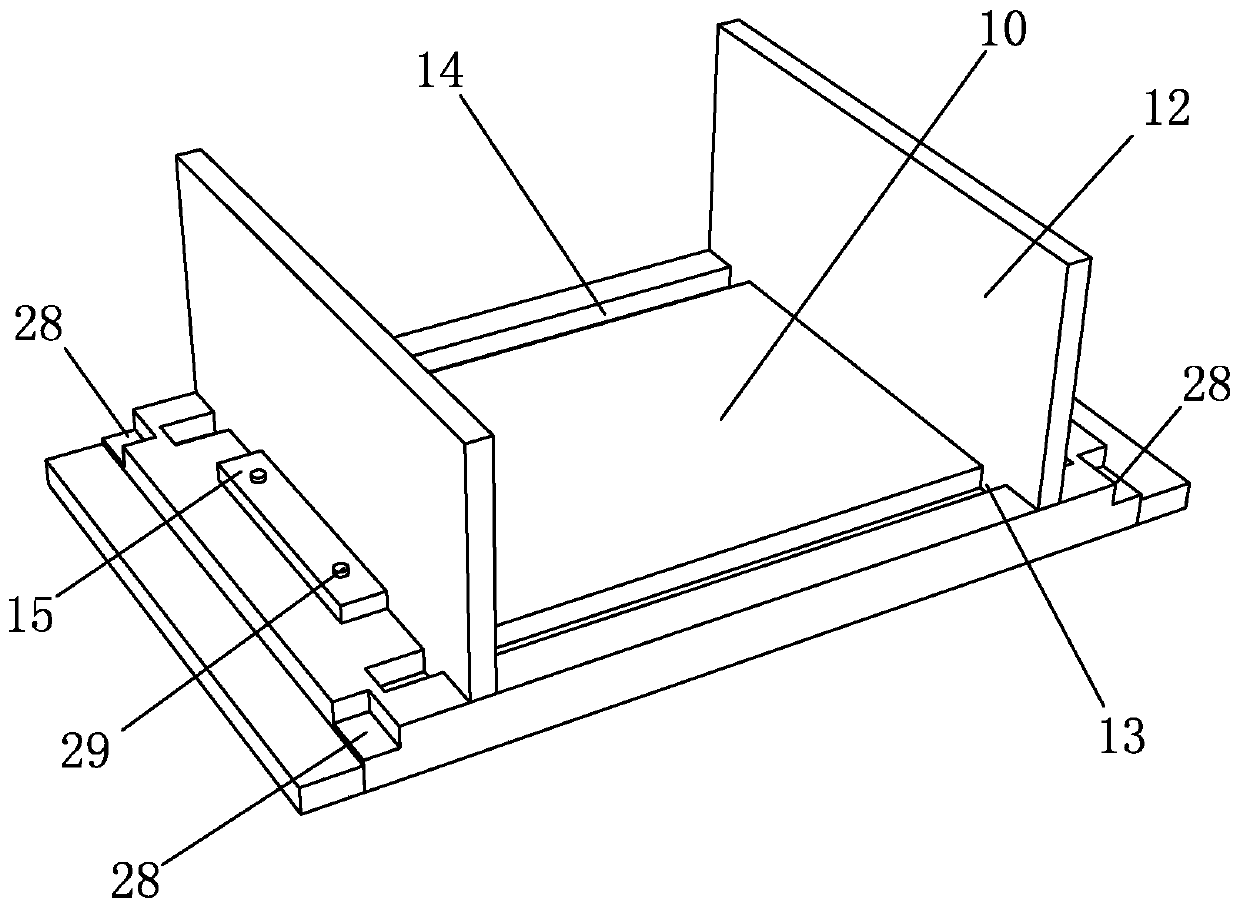

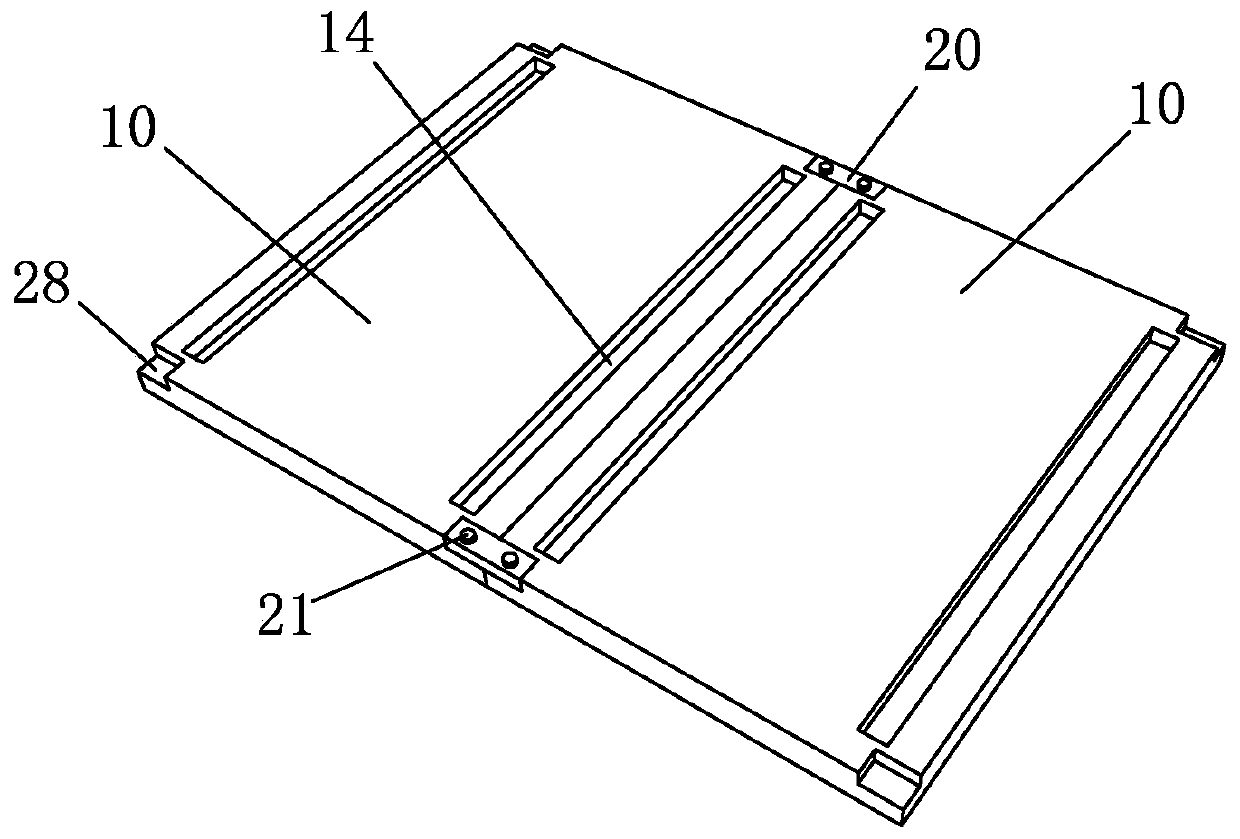

[0034] Such as Figure 1 to Figure 6 As shown, it is a method for shield tunneling of the present invention to pass through the wind shaft 24 near the river, including the following steps:

[0035] 1) Preliminary preparation: according to the tunneling direction and design requirements of the shield machine in the wind shaft 24, determine the specific position and size of the entrance and exit of the shield machine in the wind shaft 24, and then according to the actual length of the wind shaft 24, the entrance of the tunnel The position and size of the hole and the position and size of the hole are prefabricated for each part of the support frame 1, and then a layer of concrete base 27 is poured on the air shaft 24 bottom plate 9. The thickness of the concrete base 27 is 150-200mm, ensuring that the concrete base 27 has Certain support bearing capacity, the design of the concrete base 27 can ensure the flatness of the bottom surface of the air shaft 24, thereby facilitating th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com