Multipoint Synchronous Clay Core Sampler

A technology of clay and column cores, applied in the direction of sampling devices, etc., can solve the problems of failure to achieve synchronous multi-point, low contamination, increased risk of cross-contamination between column cores, and inability to achieve synchronous multi-point sampling, etc., to achieve reliable Strong operability and transformability, reducing the risk of soil cross-contamination, avoiding extrusion deformation and cross-contamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

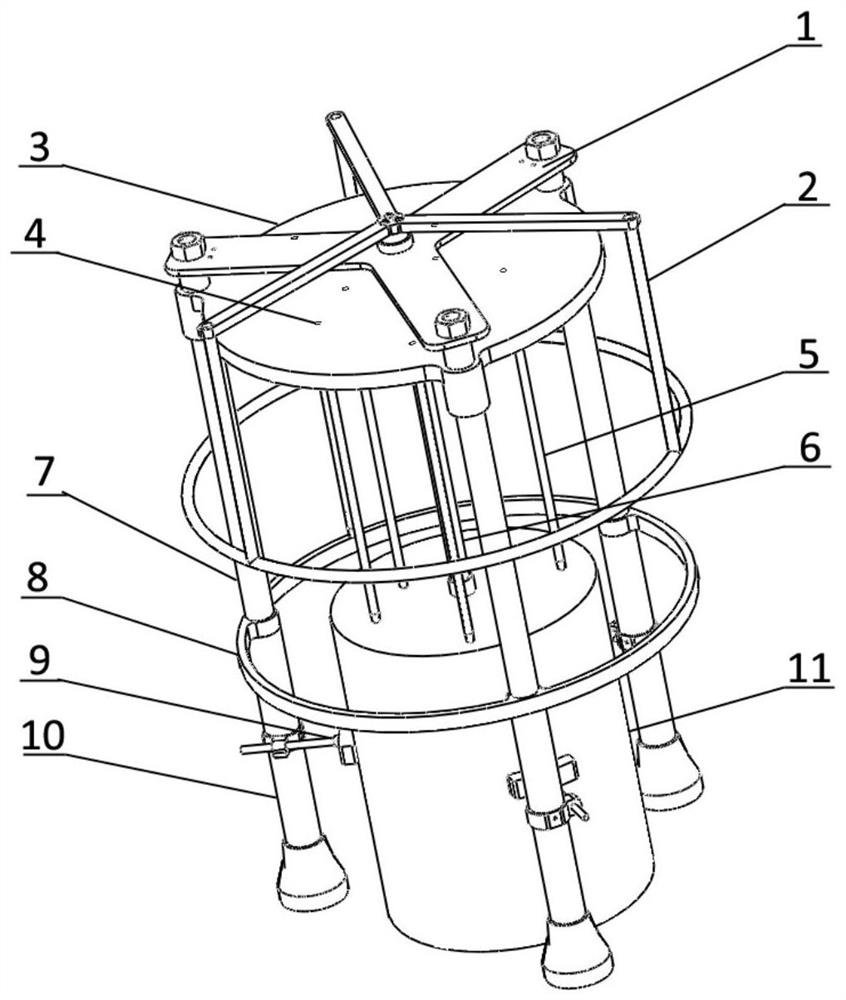

[0023] The structure of the multi-point synchronous clay core sampler is shown in figure 1 .

[0024] (1) The sampling process includes five processes: selection and installation of sampling tube, sampler and sample fixation, auger sampling, template return and sample removal.

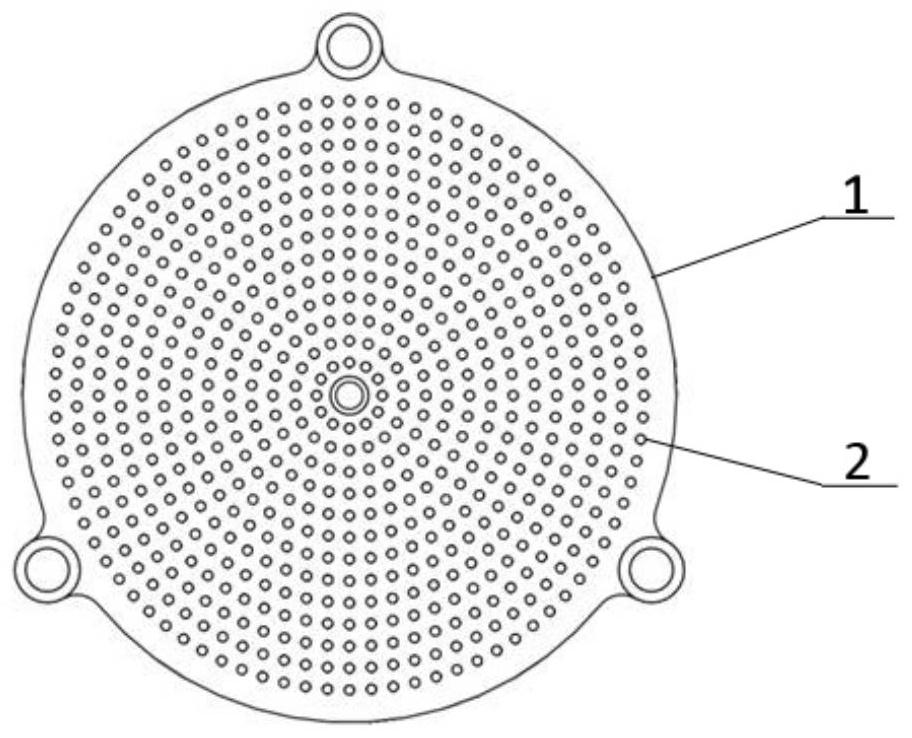

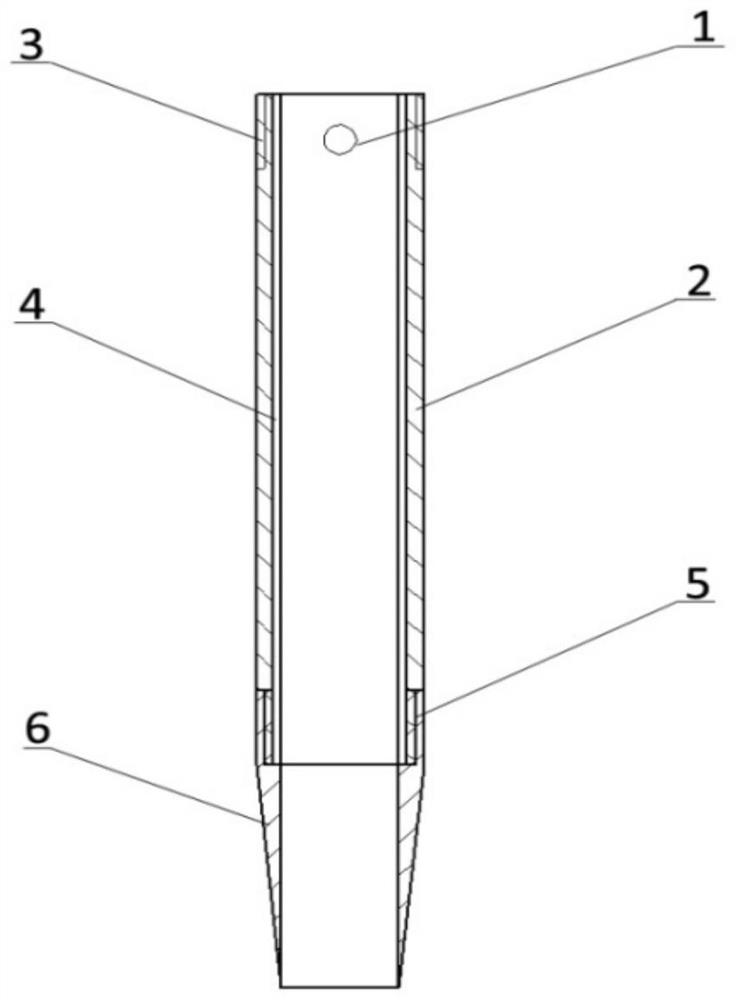

[0025] ①Selection and installation of the sampling tube [5]: According to the sampling requirements, select a group of sampling tube connection holes [4] distributed at different points on the base plate [3], and connect the sampling tube [5] of a certain diameter through threads.

[0026] ② Sampler and sample fixation: Adjust the height of the telescopic support [10] to a fixed value to ensure that the difference between its height and the height of the sampling tube [5] is greater than or equal to the height of the soil column sample [11], and perform sampling operations on the compacted soil column ; Lower the telescopic support [10] to ensure that the bottom of the sampling tube [5] remains level ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com