Laser heating measurement device and method for interface heat transfer coefficient and material thermal conductivity

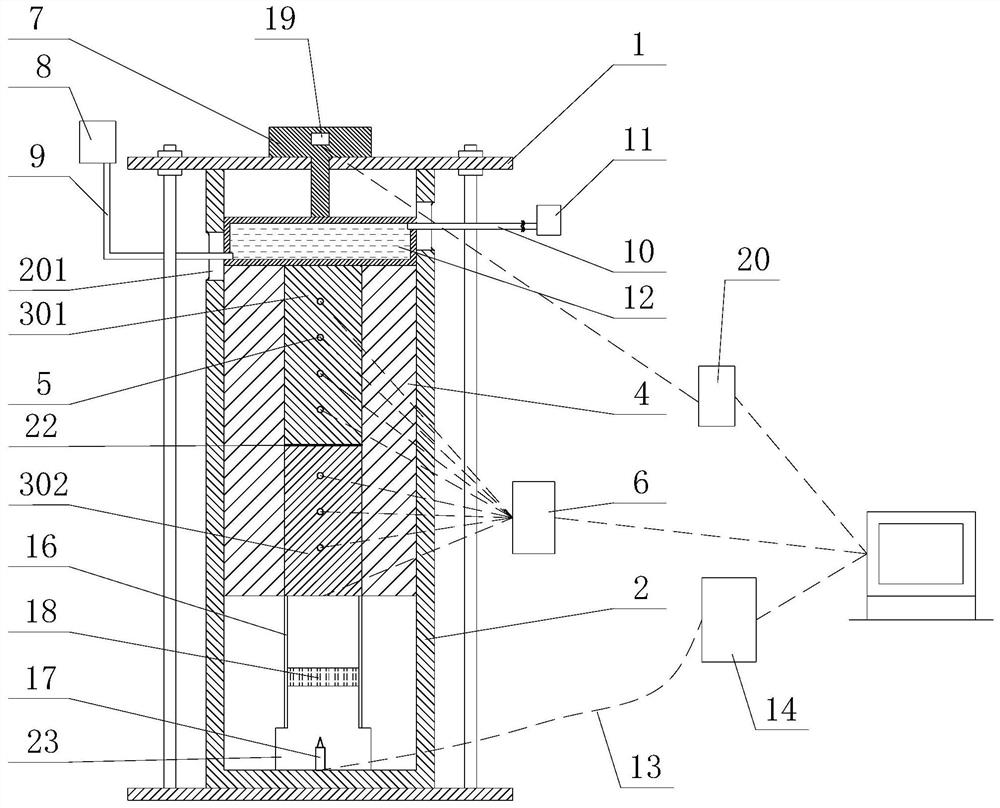

An interface heat transfer coefficient and laser heating technology, applied in the field of material thermal properties, can solve the problems of inaccurate, uneven heating temperature, slow heating rate, etc., to improve the application range and service life, and simplify the test steps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] Example 1: Thermal Conductivity Measurements of Casting Specimens

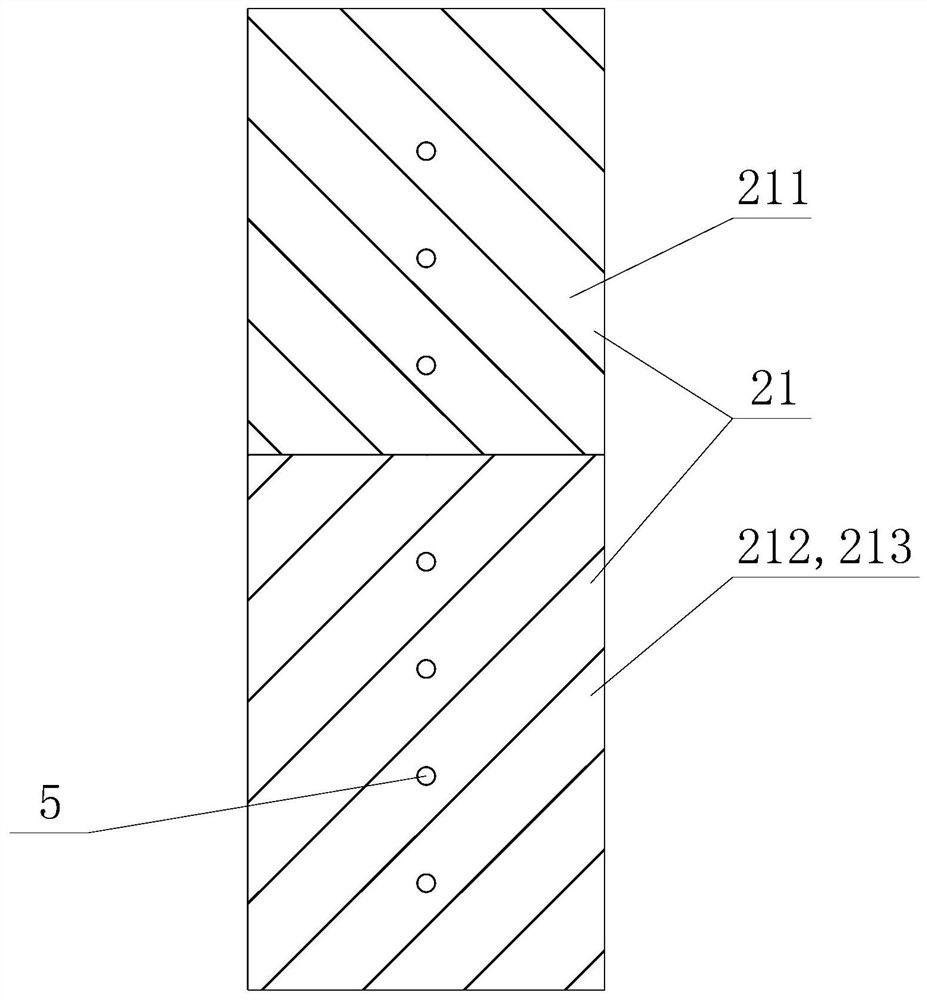

[0067] A. The selection of the second combined sample 21 and the setting of the thermocouple 5:

[0068] like figure 2 As shown, the standard sample 211 is a cylindrical brass with a diameter of 12.5 mm and a length of 60 mm, and its thermal conductivity is known, and the second casting sample 213 is a cylindrical A357 aluminum alloy with a diameter of 12.5 mm and a length of 75 mm; The side of the lower surface of the sample 211 in contact with the second casting sample 213 should be smooth enough to reduce the influence of the surface roughness on the test results.

[0069] In order to accurately obtain the axial temperature inside the second composite sample 21, four blind holes for installing the thermocouple 5 are opened on the outer surface of the second casting sample 213 at equal intervals (the spacing is 15 mm). Three blind holes for installing thermocouple 5 are opened on the outer surface ...

Embodiment 2

[0086] Example 2: Thermal Conductivity Measurement of Cast Specimens

[0087] A. The selection of the second combined sample 21 and the setting of the thermocouple 5:

[0088] The second casting sample 213 in Example 1 is replaced by a second casting sample 212, which is a cylindrical H10 steel with a diameter of 12.5 mm and a length of 75 mm, considering that the thermal conductivity belongs to the material Internal properties, so its surface does not need to be sprayed with a surface casting coating.

[0089] Then, according to parts B and C in Example 1, the thermal conductivity of the second casting mold sample 212 at each set heating temperature can be measured.

Embodiment 3

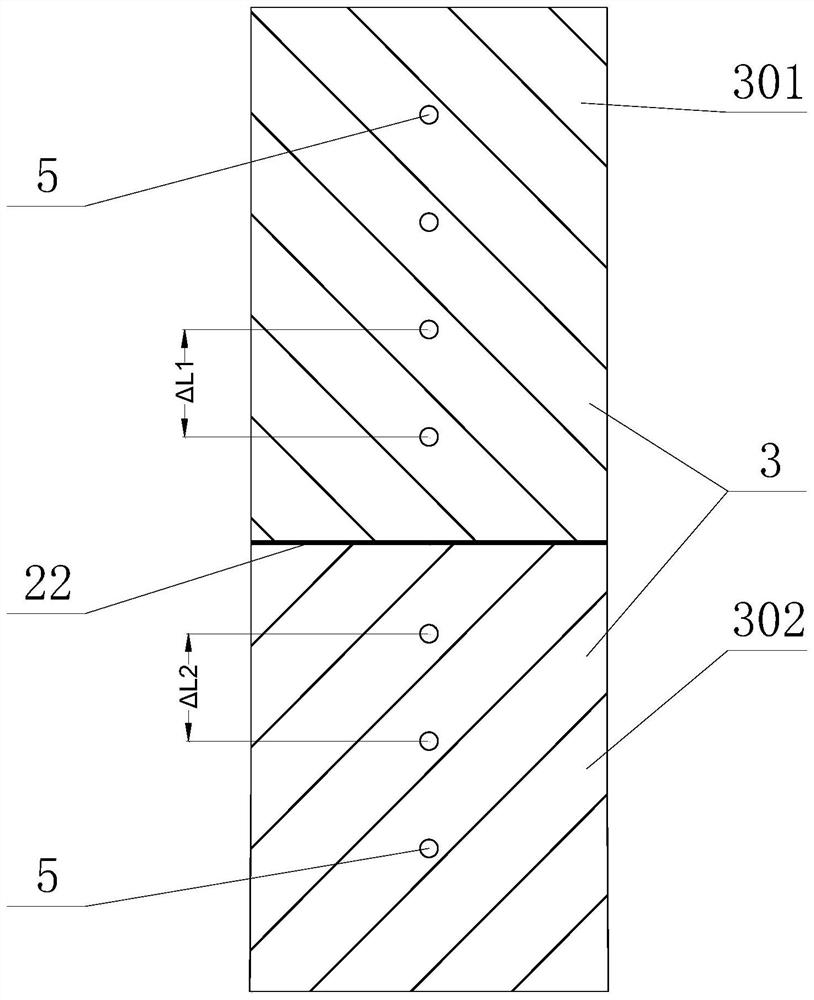

[0090] Example 3: Measurement of Interface Heat Transfer Coefficient

[0091] A. The selection of the first combined sample 3 and the setting of the thermocouple 5:

[0092] The first casting sample 302 is a cylindrical A357 aluminum alloy with a diameter of 12.5 mm and a length of 60 mm; the first casting sample 301 is a cylindrical H10 steel with a diameter of 12.5 mm and a length of 75 mm, and the casting coating 22 on the surface is sprayed In order to reduce the influence of surface roughness on the test results, the surface of the first casting sample 301 in contact with the first casting sample 302 should be smooth enough.

[0093] In order to accurately obtain the axial temperature inside the first combined sample 3, four blind holes for installing the thermocouple 5 are opened on the outer surface of the first casting sample 301 at equal intervals (the spacing is 15 mm). On the outer surface of the sample 302, three blind holes for installing the thermocouple 5 are o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com