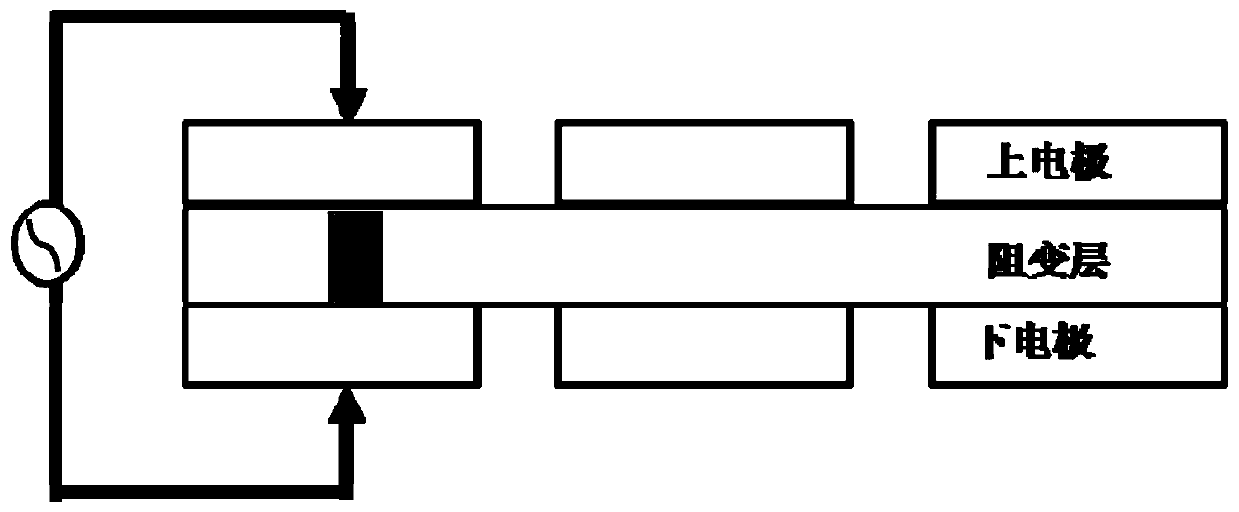

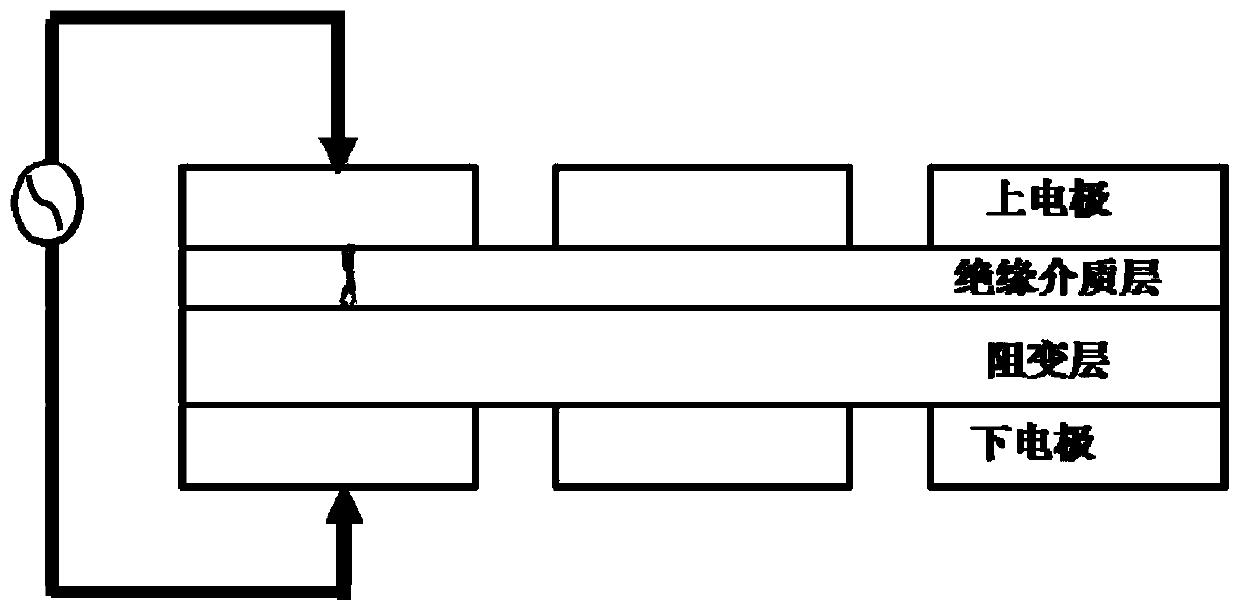

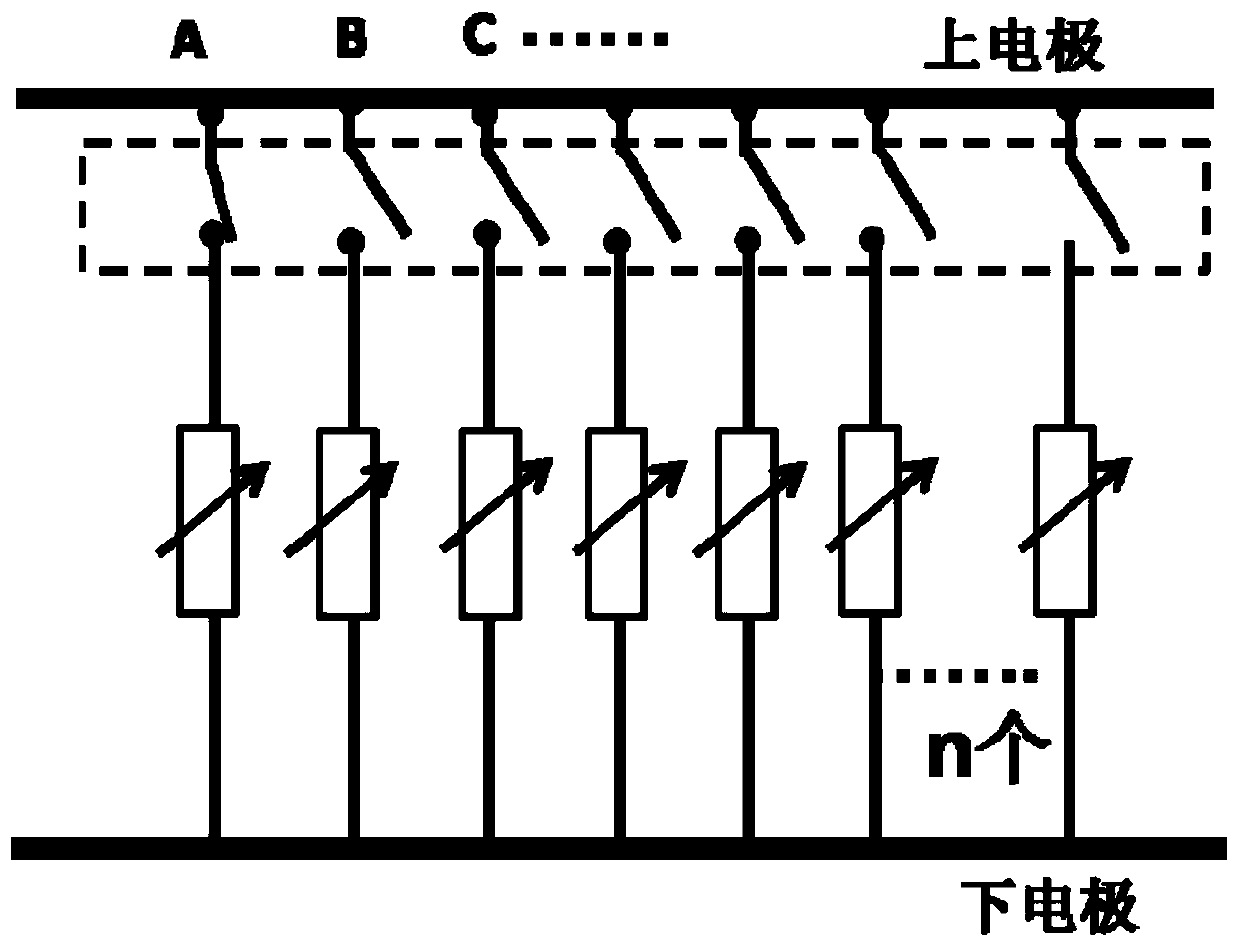

Resistive random access memory based on electrode structure reuse and preparation method thereof

A resistive variable memory and electrode technology, applied in the direction of electrical components, etc., can solve the problems of resistive variable memory cells that cannot be used and electrodes that cannot be reused, and achieve the effects of reducing area, reducing fluctuations, and reducing power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Describe the present invention in further detail below by implementing, but this is not limitation of the present invention, can make various modifications and improvements according to the basic idea of the present invention, but as long as not departing from the basic idea of the present invention, all within the scope of the invention Inside.

[0024] A copper sheet is selected as the lower electrode, and a boron nitride film is deposited on it as a resistive layer by magnetron sputtering, with a thickness of about 50nm; a plurality of aluminum metal upper electrodes with a thickness of about 150nm are deposited by using a mask plate through PVD process . The electrical characteristics are tested by a semiconductor parameter analyzer. The device is a unipolar resistive memory device that can realize unipolar operation. Its RESET voltage is concentrated around 1.3V, and the distribution range is plus or minus 0.3V, that is, RESET The voltage distribution is 1-1.6...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com