Male anti-hair loss shampoo and production process thereof

A production process and shampoo technology, applied in the field of shampoo, can solve the problems of aggravating hair loss, baldness and hair damage, excessive degreasing of the scalp, residual harmful substances, etc., to balance oil secretion, reduce hair loss, and improve toughness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

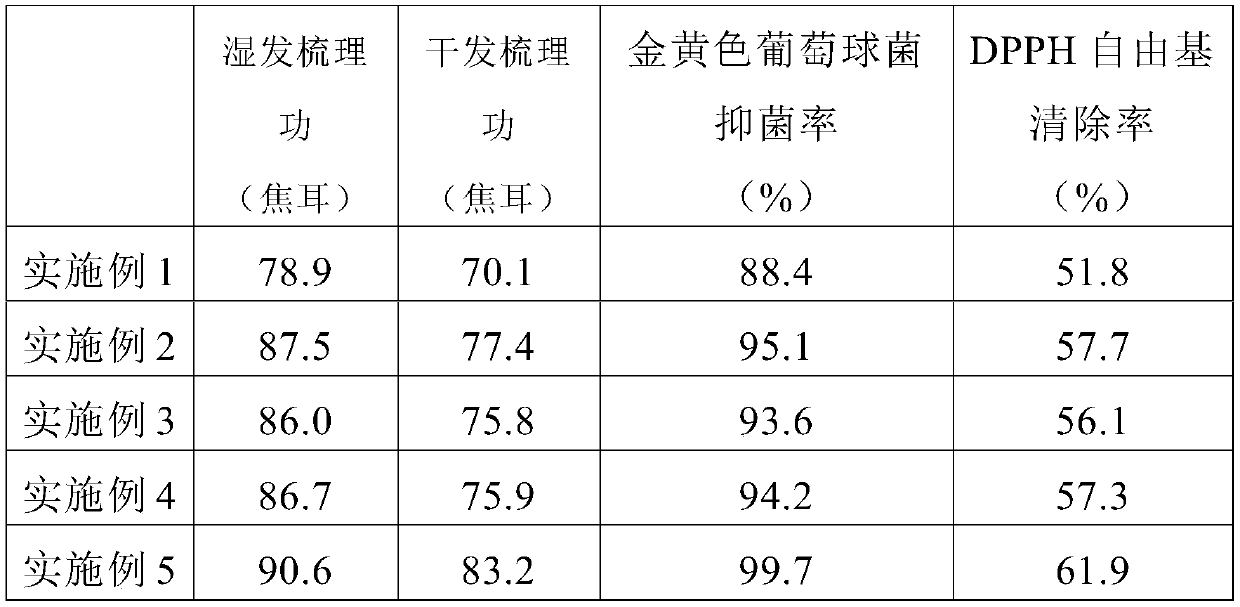

Examples

Embodiment 1

[0028] The production process of men's anti-hair loss shampoo comprises the following steps:

[0029] S1. Weigh each raw material according to mass percentage: 10% sodium lauryl polyoxyethylene ether sulfate, 3% cocoyl diethanolamine, 7% myristamidopropyl betaine, 3% sodium lauroamphoacetate, Sodium Amino Acid 6%, Lauryl Glucoside 3%, Additives 1%, Softening Agent 1.5%, Cationic Cellulose 0.8%, D-Panthenol 1.5%, Glyceryl Monooleate 1%, Traditional Chinese Medicine Extract 15% , the balance is deionized water;

[0030] S2. Heat deionized water to 65°C, add sodium lauryl polyoxyethylene ether sulfate, cocoyl diethanolamine, myristamidopropyl betaine, sodium lauroyl amphoacetate, sodium lauroyl sarcosinate, lauryl Glucoside, add additives, softening agent, cationic cellulose, glycerol monooleate and stir for 20min at a speed of 300r / min, then cool to 35°C, add D-panthenol, Chinese medicine extract and continue to rotate at a speed of 300r / min min and stirred for 30 minutes to obt...

Embodiment 2

[0037] The production process of men's anti-hair loss shampoo comprises the following steps:

[0038] S1. Weigh each raw material according to mass percentage: 10% sodium lauryl polyoxyethylene ether sulfate, 3% cocoyl diethanolamine, 7% myristamidopropyl betaine, 3% sodium lauroamphoacetate, Sodium Amino Acid 6%, Lauryl Glucoside 3%, Additives 1%, Softening Agent 1.5%, Cationic Cellulose 0.8%, D-Panthenol 1.5%, Glyceryl Monooleate 1%, Traditional Chinese Medicine Extract 15% , the balance is deionized water;

[0039] S2. Heat deionized water to 65°C, add sodium lauryl polyoxyethylene ether sulfate, cocoyl diethanolamine, myristamidopropyl betaine, sodium lauroyl amphoacetate, sodium lauroyl sarcosinate, lauryl Glucoside, add additives, softening agent, cationic cellulose, glycerol monooleate and stir for 20min at a speed of 300r / min, then cool to 35°C, add D-panthenol, Chinese medicine extract and continue to rotate at a speed of 300r / min min and stirred for 30 minutes to o...

Embodiment 3

[0047] The production process of men's anti-hair loss shampoo comprises the following steps:

[0048] S1. Weigh each raw material according to mass percentage: 10% sodium lauryl polyoxyethylene ether sulfate, 3% cocoyl diethanolamine, 7% myristamidopropyl betaine, 3% sodium lauroamphoacetate, Sodium Amino Acid 6%, Lauryl Glucoside 3%, Additives 1%, Softening Agent 1.5%, Cationic Cellulose 0.8%, D-Panthenol 1.5%, Glyceryl Monooleate 1%, Traditional Chinese Medicine Extract 15% , the balance is deionized water;

[0049] S2. Heat deionized water to 65°C, add sodium lauryl polyoxyethylene ether sulfate, cocoyl diethanolamine, myristamidopropyl betaine, sodium lauroyl amphoacetate, sodium lauroyl sarcosinate, lauryl Glucoside, add additives, softening agent, cationic cellulose, glycerol monooleate and stir for 20min at a speed of 300r / min, then cool to 35°C, add D-panthenol, Chinese medicine extract and continue to rotate at a speed of 300r / min min and stirred for 30 minutes to o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com