Raw material outer circulation final grinding system using self-screening function vertical mill and application

A circulation system and external circulation technology, applied in the direction of filter screen, solid separation, grille, etc., can solve the problems of high investment cost, high workshop height, high power consumption of vertical mill ventilation, etc., to reduce cycle load, increase residence time, Reduce the effect of escape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

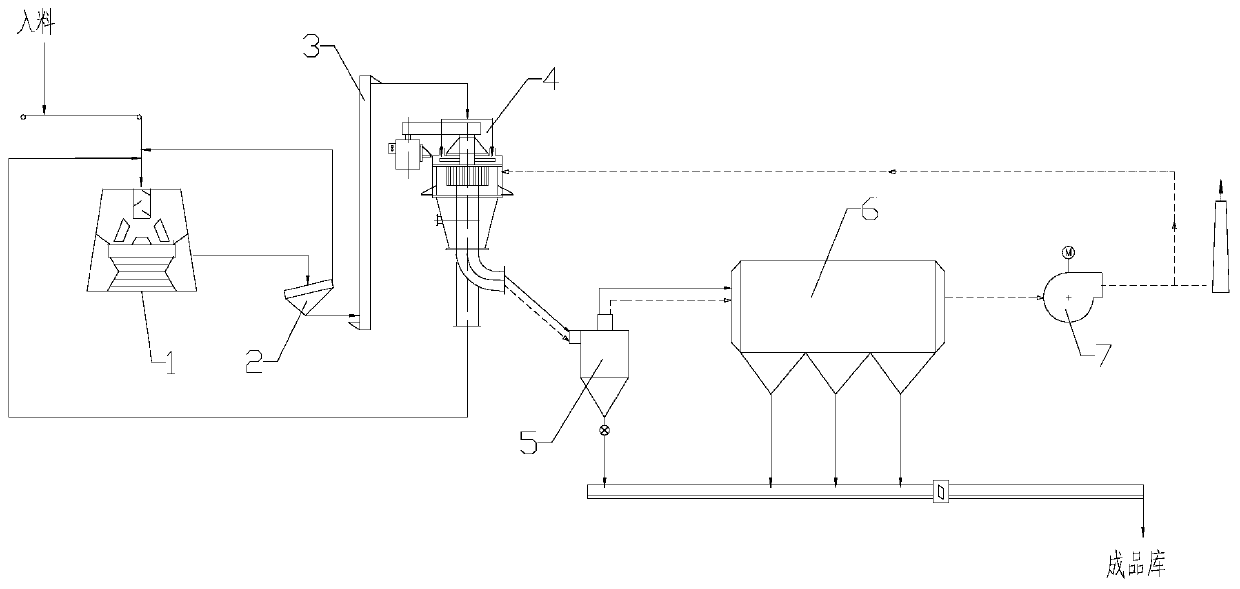

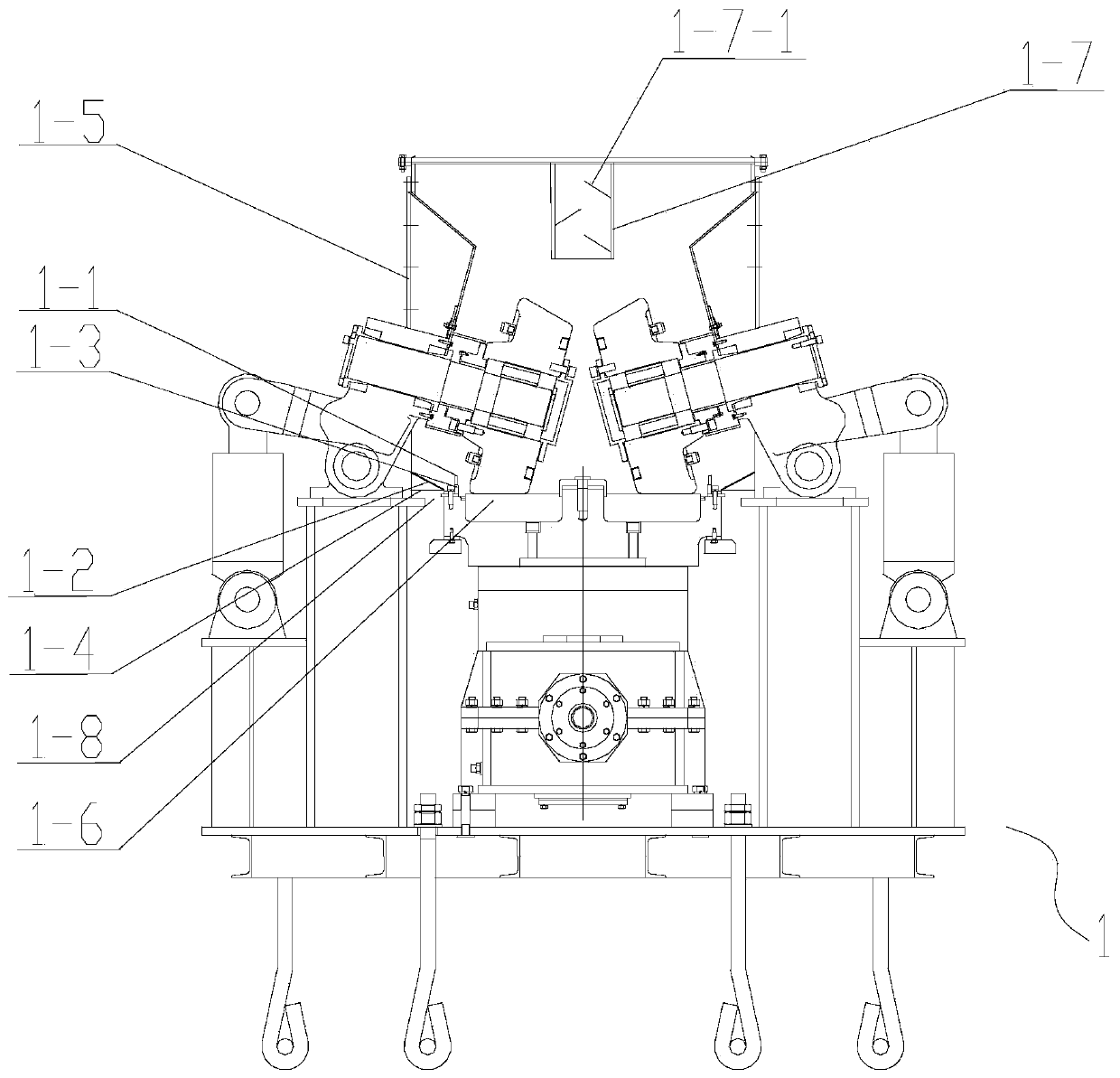

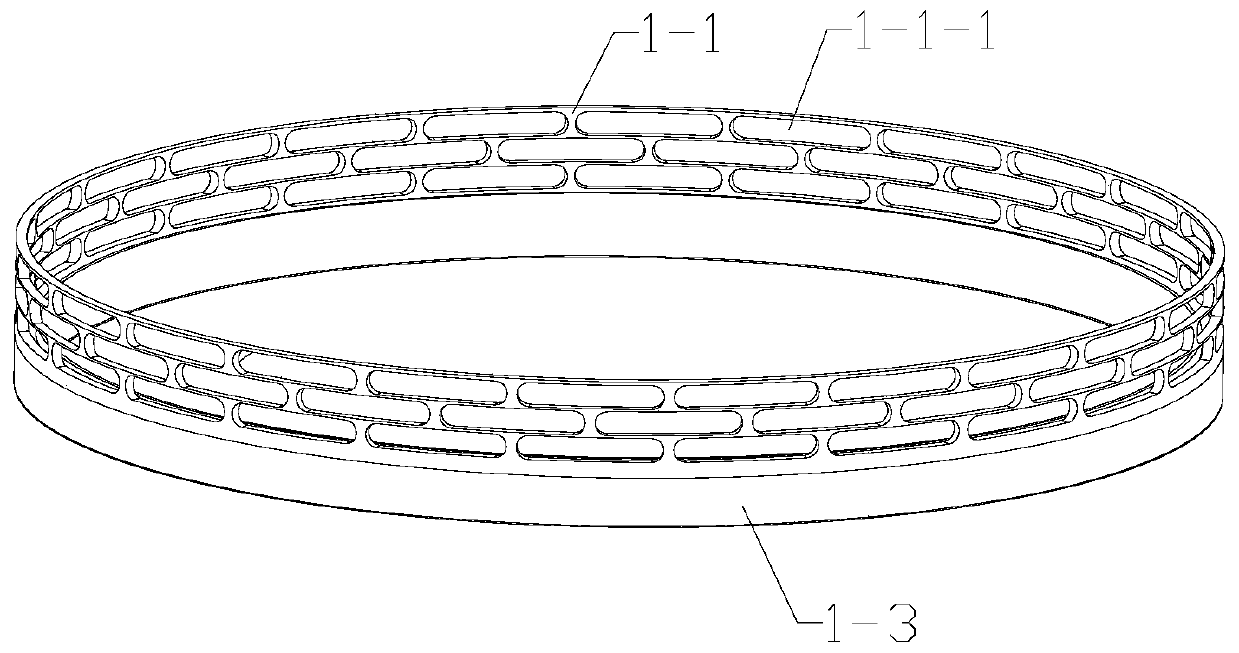

[0045] see Figure 1-5 , this embodiment provides a raw material external circulation final grinding system using a vertical mill with a self-screening function, including a vertical mill 1, a vibrating screen 2, an elevator 3, a dynamic powder separator 4 and a cyclone 5; Mill 1 and vibrating screen 2 are connected to form a circulation system; the vertical mill 1, vibrating screen 2, elevator 3 and dynamic powder separator 4 are connected in sequence to form a circulation system; the vertical mill 1, vibrating screen 2, Elevator 3, dynamic powder classifier 4, and cyclone 5 are connected in sequence to form a raw material final grinding system.

[0046] The material is ground by the vertical mill with self-sieving function, and the preliminary screening is completed inside the vertical mill, and the particles below 10mm are discharged from the mill; the material is secondarily sieved by the vibrating screen during the falling process, and the fine powder after sieving (≤2mm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com