High-temperature-resistant multi-layer composite heat-insulating component and preparation method thereof

A multi-layer composite, high temperature resistant technology, applied in vehicle parts, chemical instruments and methods, lamination and other directions, can solve the problems of low use temperature, low aluminum density, not suitable for high temperature heat insulation environment, etc., and achieve good heat insulation effect , The preparation method is simple and feasible, and the thermal insulation effect is excellent in stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

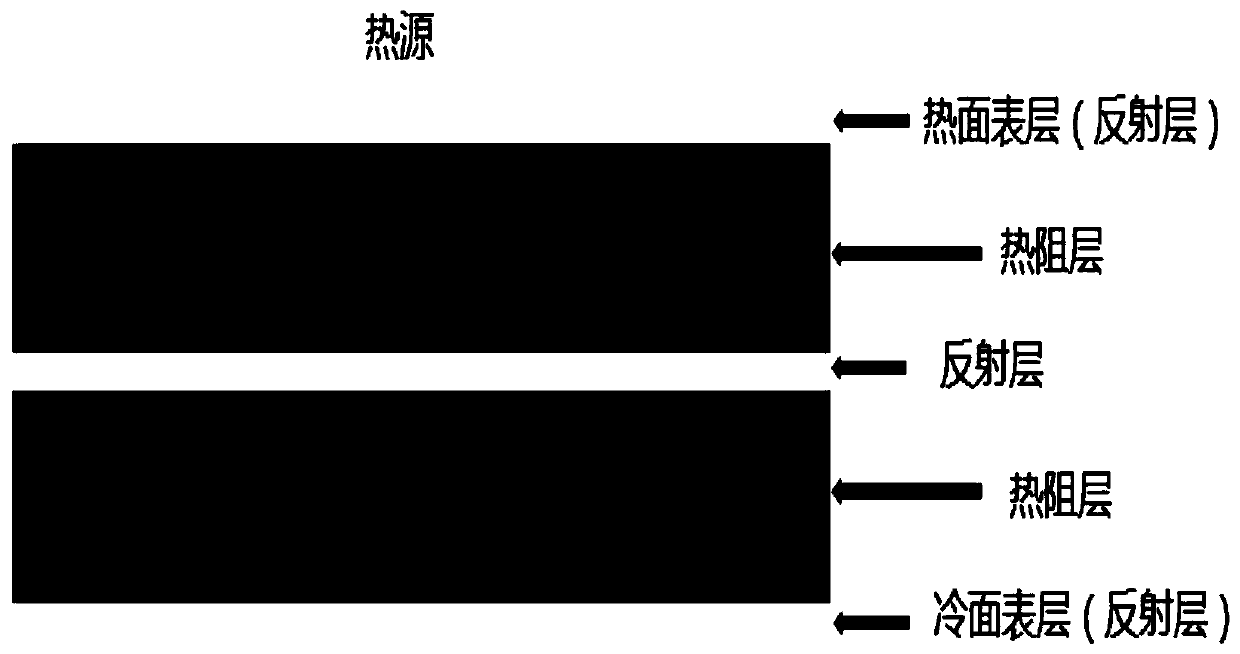

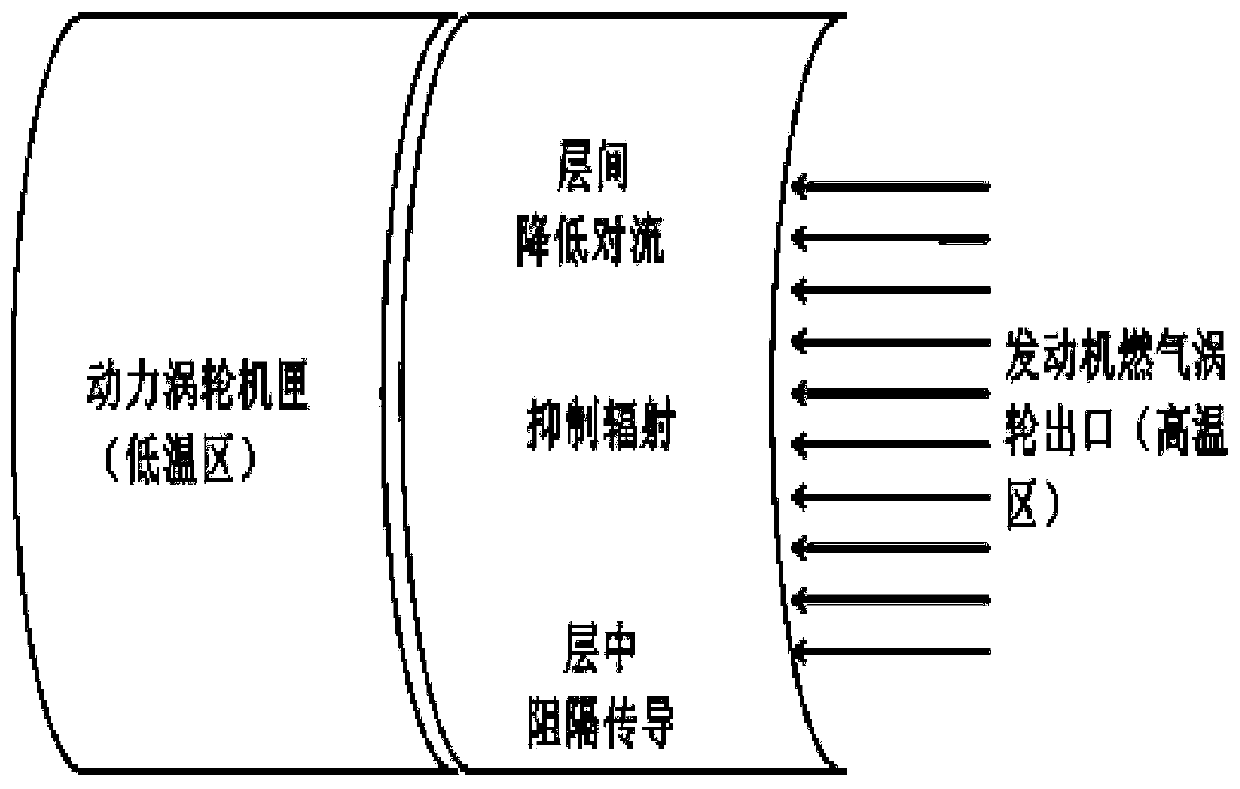

[0024] A high temperature resistant multilayer composite heat insulation component: it is composed of a reflection layer and a heat resistance layer laminated, the reflection layer close to the hot surface is the surface layer of the heat insulation component, and the reflection layer close to the cold surface is the surface layer of the heat insulation component The surface layer of the cold surface, the reflective layer is a metal foil coated with a high reflectivity material, the heat resistance layer is a heat insulating material with a low thermal conductivity; the high reflectivity material is silver, and the low thermal conductivity The thermal insulation material is ceramic fiber paper; the reflective layer is stainless steel foil with silver-plated surface, and its thickness is 0.033mm; the above-mentioned thermal resistance layer is ceramic fiber paper, and its thickness is 0.26mm; The total thickness is not more than 2mm.

[0025] The preparation method of the above...

Embodiment 2

[0045] A high temperature resistant multilayer composite heat insulation component: it is composed of a reflection layer and a heat resistance layer laminated, the reflection layer close to the hot surface is the surface layer of the heat insulation component, and the reflection layer close to the cold surface is the surface layer of the heat insulation component The surface layer of the cold surface, the reflective layer is a metal foil coated with a high reflectivity material, the heat resistance layer is a heat insulating material with a low thermal conductivity; the high reflectivity material is silver, and the low thermal conductivity The thermal insulation material is ceramic fiber paper; the reflective layer is stainless steel foil with silver-plated surface, and its thickness is 0.03mm; the above-mentioned thermal resistance layer is ceramic fiber paper, and its thickness is 0.25mm; The total thickness is not more than 2mm.

[0046] The preparation method of the above-...

Embodiment 3

[0049] A high temperature resistant multilayer composite heat insulation component: it is composed of a reflection layer and a heat resistance layer laminated, the reflection layer close to the hot surface is the surface layer of the heat insulation component, and the reflection layer close to the cold surface is the surface layer of the heat insulation component The surface layer of the cold surface, the reflective layer is a metal foil coated with a high reflectivity material, the heat resistance layer is a heat insulating material with a low thermal conductivity; the high reflectivity material is silver, and the low thermal conductivity The thermal insulation material is ceramic fiber paper; the reflective layer is stainless steel foil with silver-plated surface, and its thickness is 0.035mm; the above-mentioned thermal resistance layer is ceramic fiber paper, and its thickness is 0.27mm; The total thickness is not more than 2mm.

[0050] The preparation method of the above...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com