Method for effectively and continuously extracting selenium active component in moringa seeds

An extraction method and a technology of active ingredients, which are applied in the extraction field of effective maintenance of selenium active ingredients in Moringa oleifera seeds, can solve the problems of not knowing how to maintain selenium, not involving the selenium content in Moringa oleifera seed polysaccharides, etc., and achieve the effect of less loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0088] 1) The Moringa oleifera seeds were dried at a constant temperature of 40°C, crushed, passed through a 100-mesh molecular sieve, and the obtained Moringa oleifera seed powder and petroleum ether were soaked at a solid-liquid ratio of 1g:3mL for 7 days to degrease, and the petroleum ether was recovered by distillation under reduced pressure, and the residue was placed in After volatilizing the solvent in a ventilated place, the defatted Moringa seed powder is obtained;

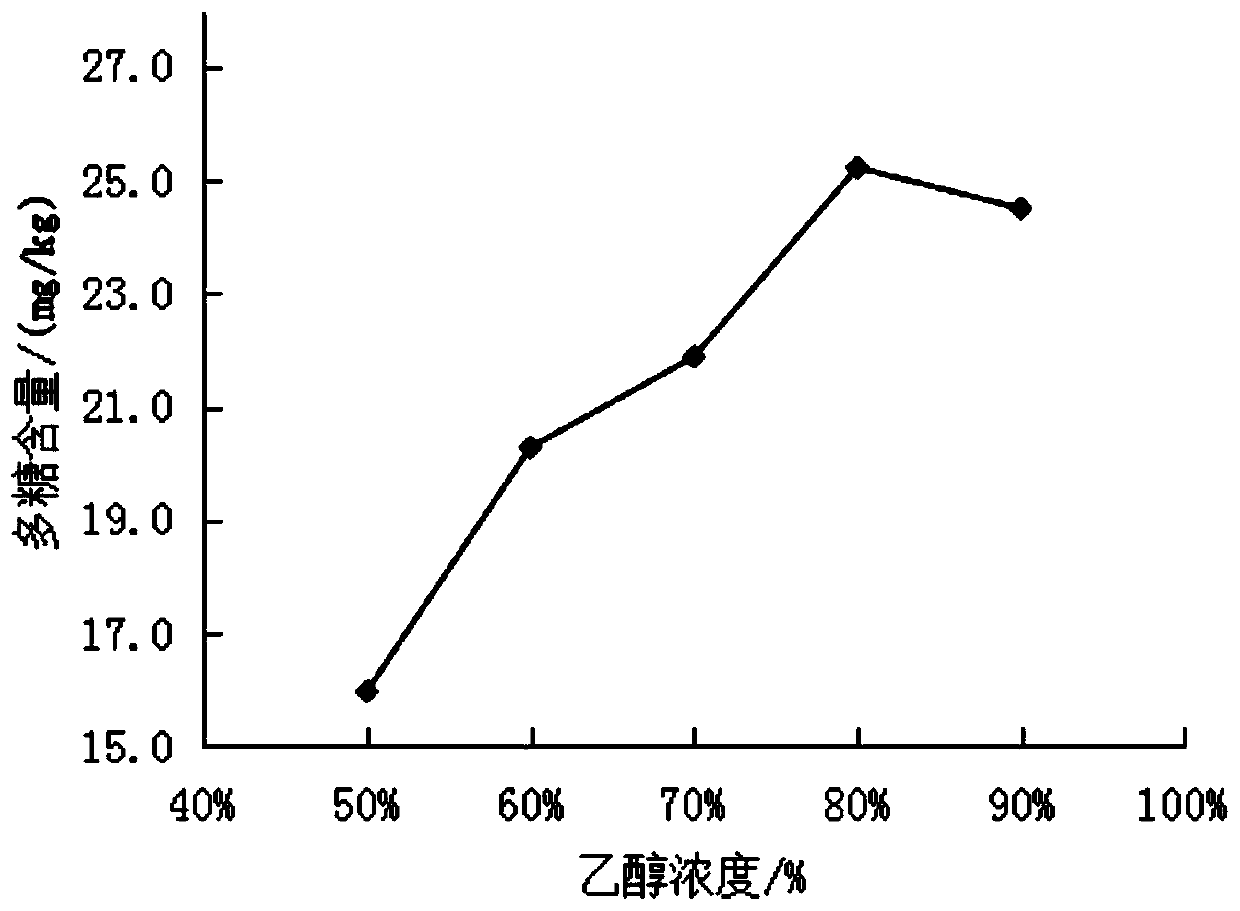

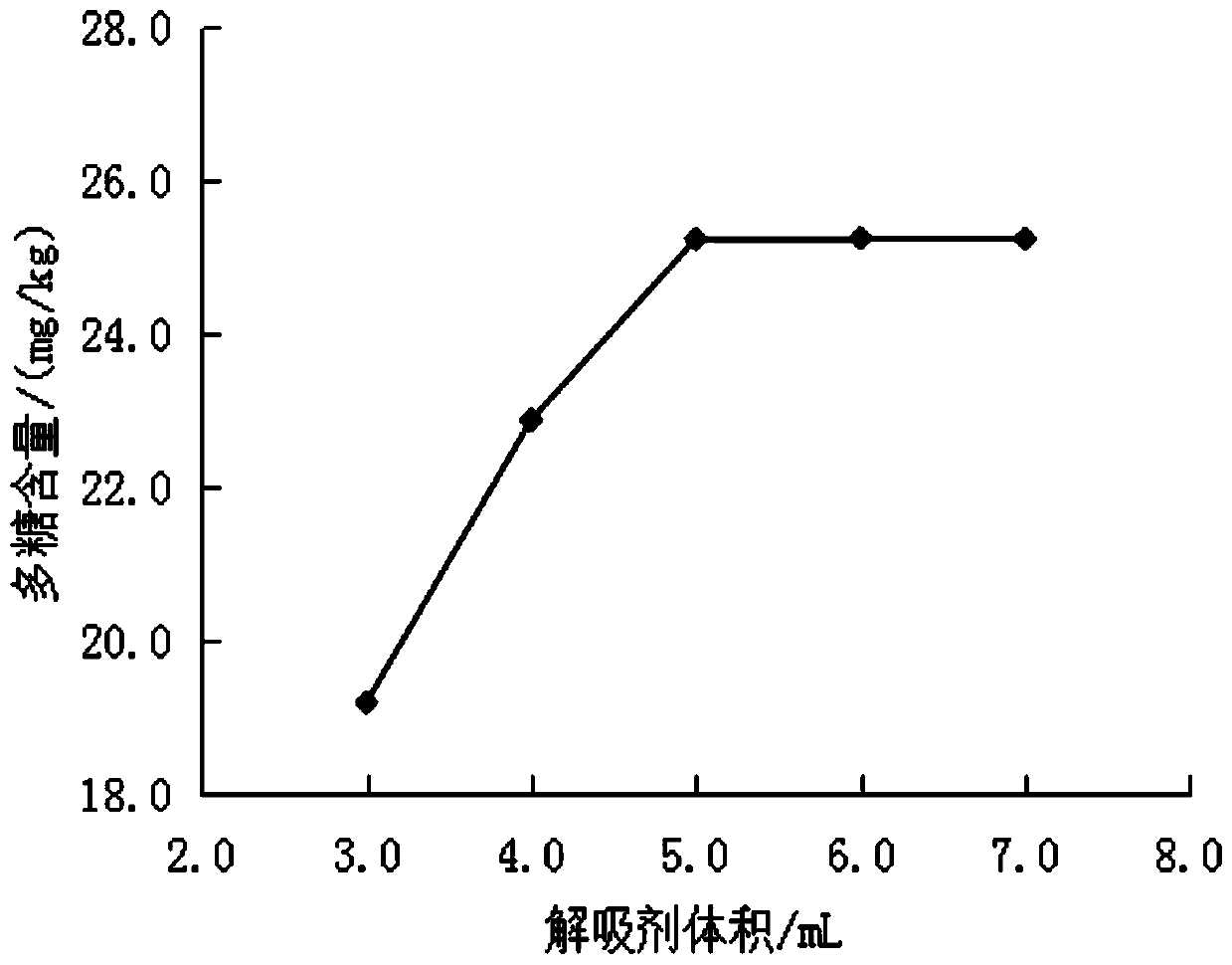

[0089] 2) Put 2g of degreased Moringa oleifera seed powder in a flask, add 80v / v% ethanol for desorption at a solid-liquid ratio of 5.0mL / g for 25min, then immediately add 50mL of 80°C hot water for extraction for 6min, suction filter, and repeat the above for the filter residue Extract once, combine filtrate, promptly obtain 104.5mL Moringa seed polysaccharide solution; Measure (below the same) selenium content in Moringa seed polysaccharide solution by the method described in aforementioned 1.2.3, be 3.0...

Embodiment 2

[0098] 1) The Moringa oleifera seeds were dried at a constant temperature of 40°C, crushed, passed through a 100-mesh molecular sieve, and the obtained Moringa oleifera seed powder and petroleum ether were soaked at a solid-liquid ratio of 1g:5mL for 5 days to degrease, and the petroleum ether was recovered by distillation under reduced pressure. After volatilizing the solvent in a ventilated place, the defatted Moringa seed powder is obtained;

[0099] 2) Put 2g of degreased Moringa oleifera seed powder in a flask, add 80v / v% ethanol for desorption at a solid-liquid ratio of 6.0mL / g for 30min, then immediately add 50mL of 80°C hot water for extraction for 7min, suction filter, and repeat the above for the filter residue Extract once, combine filtrate, promptly obtain 106mL Moringa seed polysaccharide solution;

[0100] 3) The obtained Moringa oleifera seed polysaccharide solution is concentrated to a paste, then Sevage reagent is added thereto, fully oscillated, stirred for 3...

Embodiment 3

[0102] 1) The Moringa oleifera seeds were dried at a constant temperature of 40°C, crushed, passed through a 100-mesh molecular sieve, and the obtained Moringa oleifera seed powder and petroleum ether were soaked at a solid-liquid ratio of 1g:4mL for 6 days to degrease, and the petroleum ether was recovered by distillation under reduced pressure. After volatilizing the solvent in a ventilated place, the defatted Moringa seed powder is obtained;

[0103] 2) Put 2g of degreased Moringa oleifera seed powder in a flask, add 80v / v% ethanol for desorption at a solid-liquid ratio of 5.0mL / g for 25min, then immediately add 40mL of 80°C hot water for extraction for 7min, suction filter, and repeat the above for the filter residue Extract once, combine filtrate, promptly obtain 85.5mL Moringa oleifera seed polysaccharide solution;

[0104] 3) The obtained Moringa oleifera seed polysaccharide solution is concentrated to a paste, then Sevage reagent is added thereto, fully oscillated, sti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com