Switchable glass and manufacturing method thereof

A technology of dimming glass and its manufacturing method, which is applied in the direction of parallel glass structure, chemical instruments and methods, optics, etc., and can solve problems such as unreasonable composition ratio of interlayer and unsatisfactory adhesion between interlayer and glass, so as to avoid Appearance defects of blistering and delamination, saving production materials, and enhancing the effect of impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

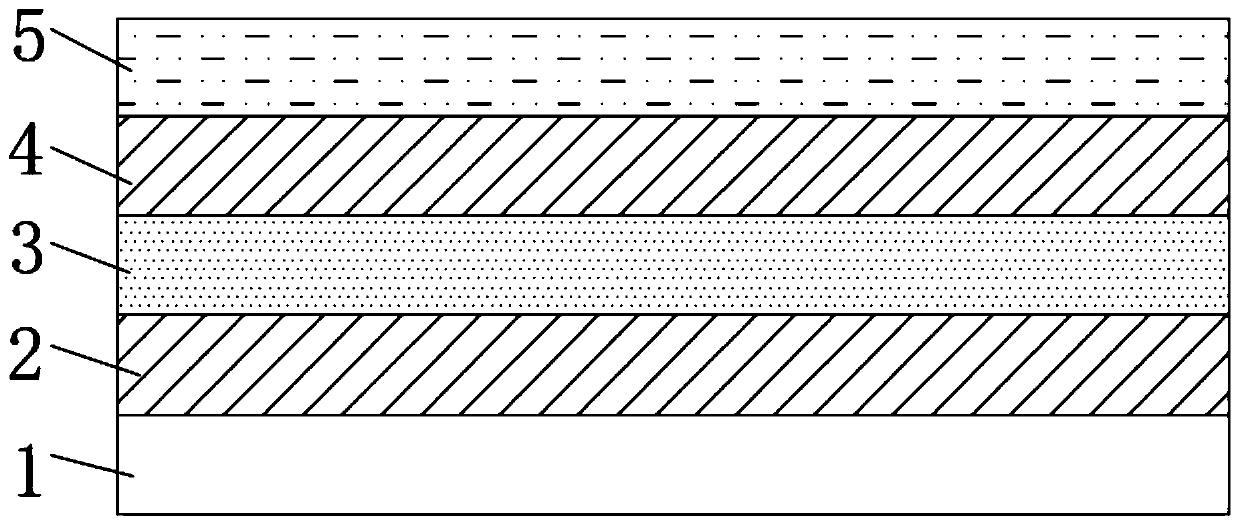

[0047] A dimming glass, comprising a glass 1, one side of the glass 1 is fixedly connected to one side of a first adhesive layer 2, the other side of the first adhesive layer 2 is fixedly connected to one side of a conductive dimming layer 3, The other side of the optical layer 3 is fixedly connected to one side of the second adhesive layer 4, and the other side of the second adhesive layer 4 is fixedly connected to the side of the hard protective film layer 5;

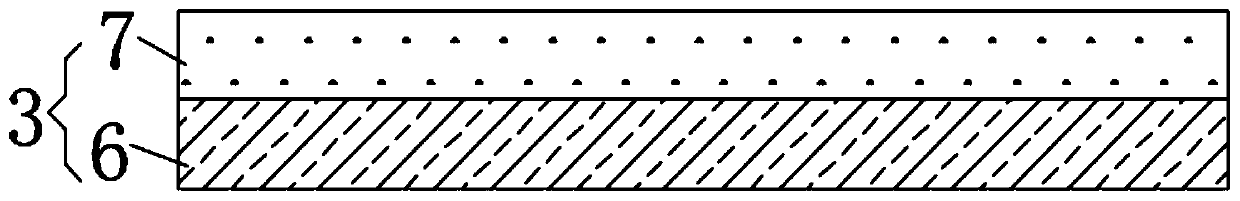

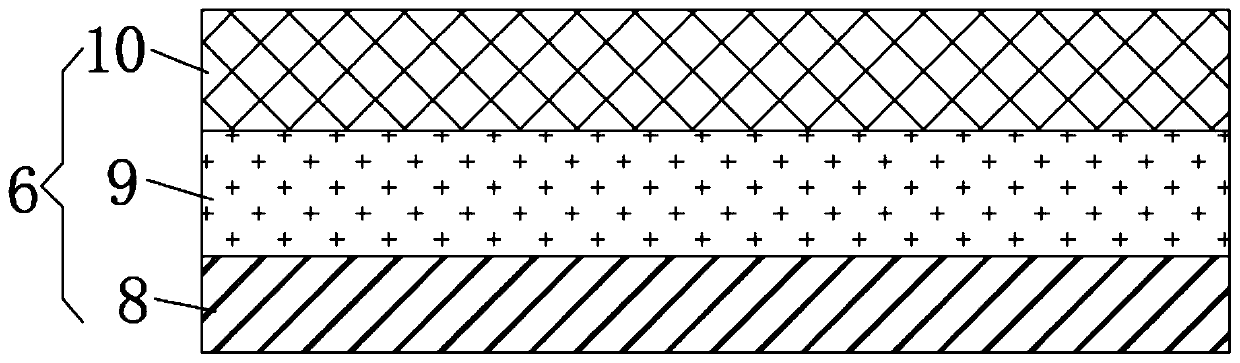

[0048] The conductive dimming layer 3 includes a conductive hard film 6 and a polymer dispersed liquid crystal layer 7 .

[0049] A method for making dimming glass, characterized in that it comprises the following steps:

[0050] Step 1: build a layer, the vinyl acetate copolymer and polyvinyl chloride are configured into a solution in proportion, and the content proportion of the solution is (by mass percentage): vinyl acetate copolymer: 76%, polyvinyl chloride: 24%, and then the solution Dropping it on a horizontal...

Embodiment 2

[0058] A dimming glass, comprising a glass 1, one side of the glass 1 is fixedly connected to one side of a first adhesive layer 2, the other side of the first adhesive layer 2 is fixedly connected to one side of a conductive dimming layer 3, The other side of the optical layer 3 is fixedly connected to one side of the second adhesive layer 4, and the other side of the second adhesive layer 4 is fixedly connected to the side of the hard protective film layer 5;

[0059] The conductive dimming layer 3 includes a conductive hard film 6 and a polymer dispersed liquid crystal layer 7 .

[0060] A method for making dimming glass, characterized in that it comprises the following steps:

[0061] Step 1: layering, the vinyl acetate copolymer and polyvinyl chloride are configured into a solution in proportion, and the content proportion of the solution is (by mass percentage): vinyl acetate copolymer: 75%, polyvinyl chloride: 25%, and then the solution Dropping it on a horizontal turn...

Embodiment 3

[0069] A dimming glass, comprising a glass 1, one side of the glass 1 is fixedly connected to one side of a first adhesive layer 2, the other side of the first adhesive layer 2 is fixedly connected to one side of a conductive dimming layer 3, The other side of the optical layer 3 is fixedly connected to one side of the second adhesive layer 4, and the other side of the second adhesive layer 4 is fixedly connected to the side of the hard protective film layer 5;

[0070] The conductive dimming layer 3 includes a conductive hard film 6 and a polymer dispersed liquid crystal layer 7 .

[0071] A method for making dimming glass, characterized in that it comprises the following steps:.

[0072] Step 1: build a layer, the vinyl acetate copolymer and polyvinyl chloride are configured into a solution in proportion, and the content proportion of the solution is (by mass percentage): vinyl acetate copolymer: 74%, polyvinyl chloride: 26%, and then the solution Dropping it on a horizonta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com