Shaft medical gas multifunctional control system

A control system and multi-functional technology, which is applied in the pipeline system, gas/liquid distribution and storage, mechanical equipment, etc., can solve the problem of inconvenient pipeline gas detection and control, Complicated installation of gas supply pipelines, etc., to facilitate pipeline monitoring and control, repair and maintenance, facilitate engineering layout and installation and fixation, and reduce layout settings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

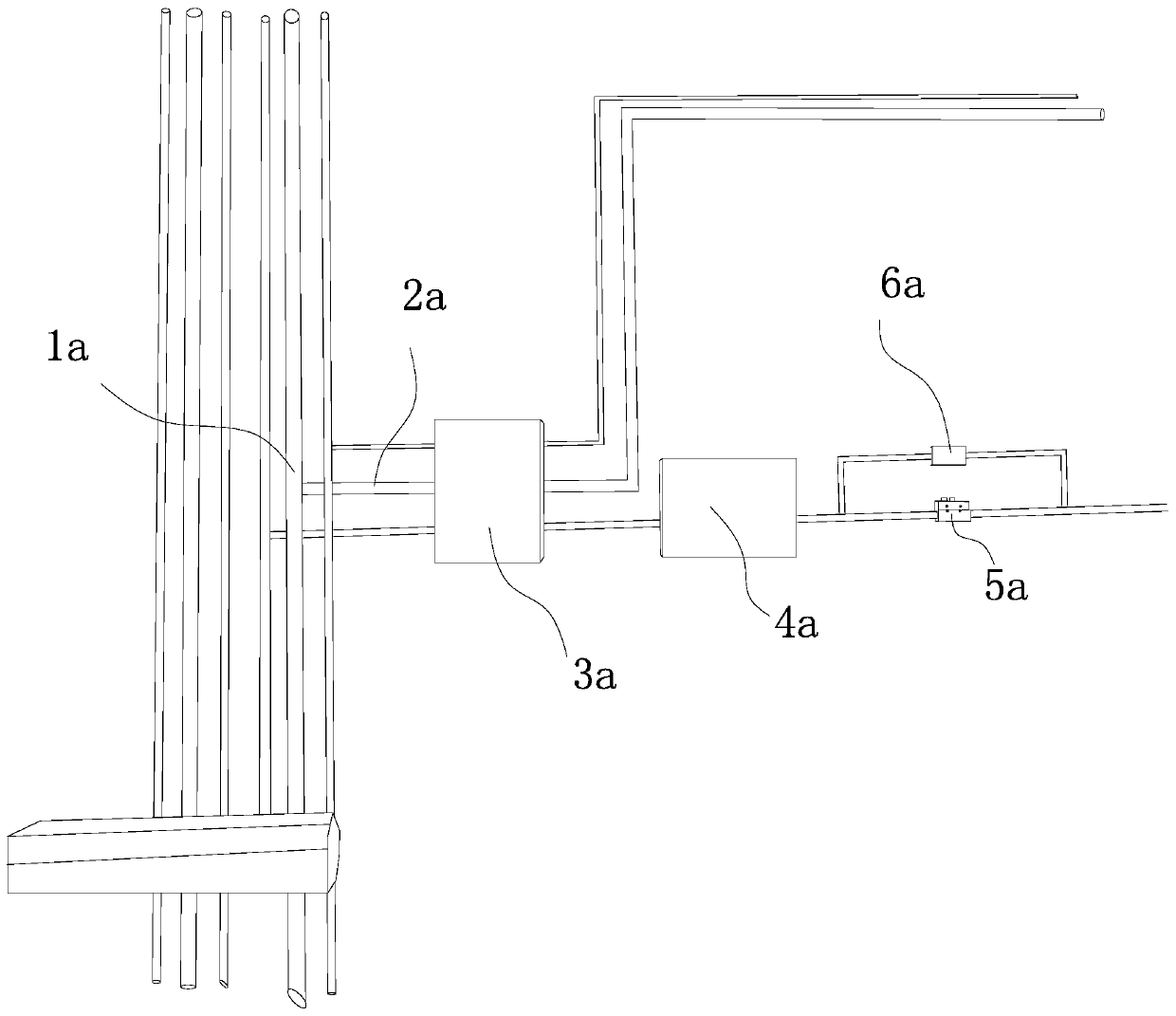

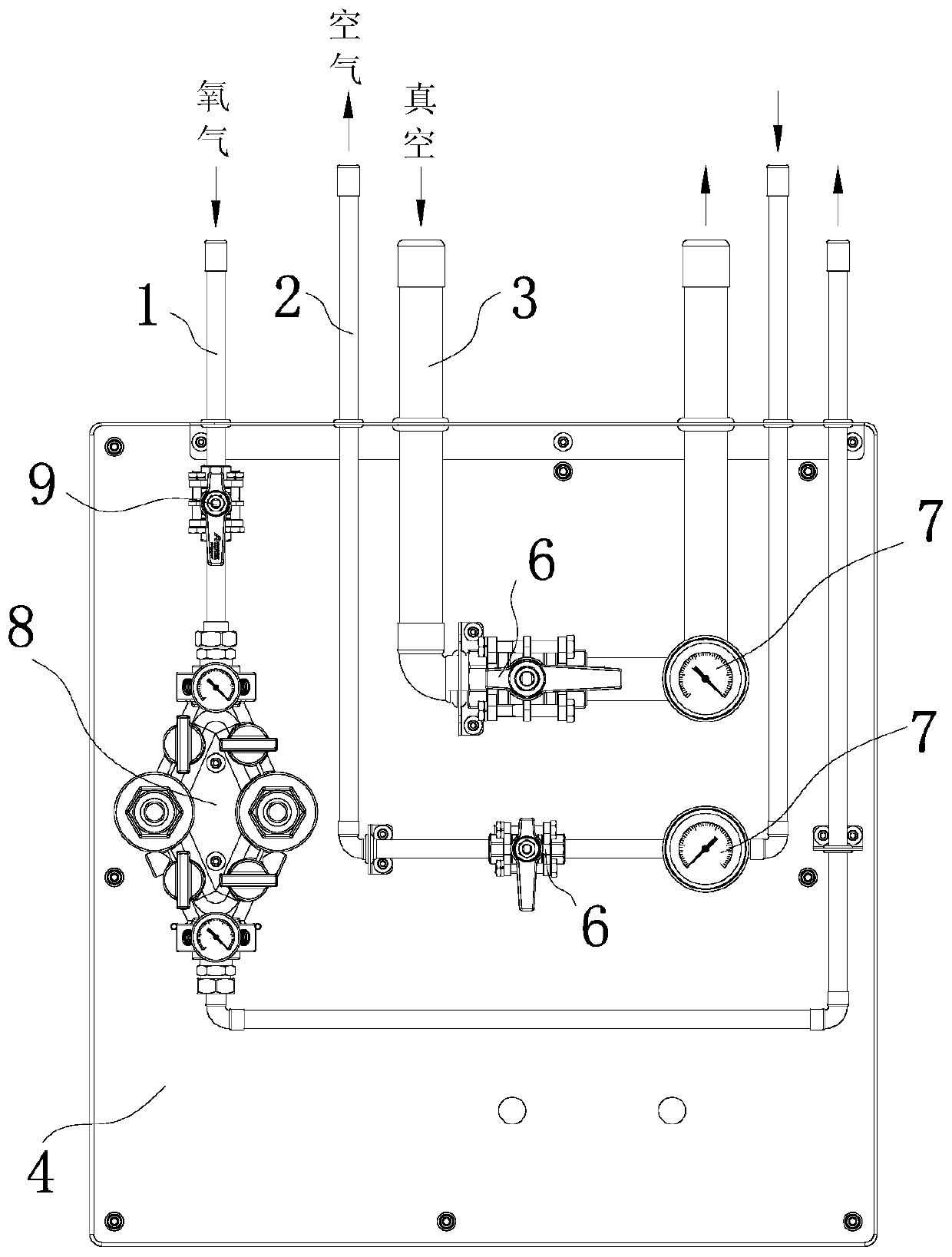

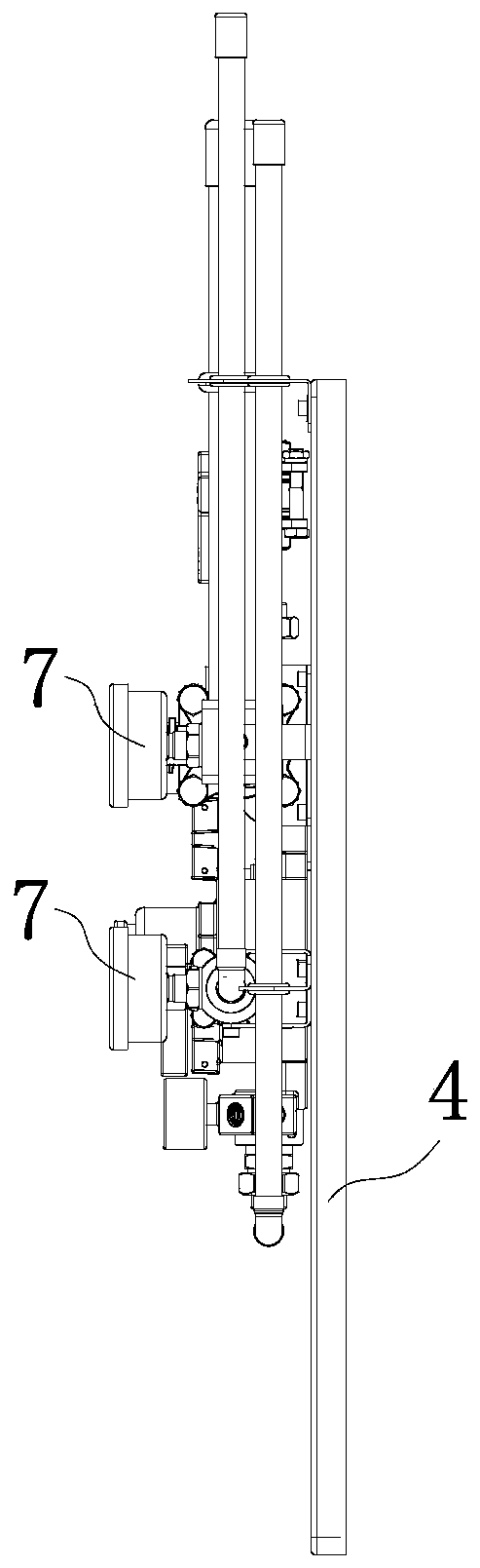

[0046] Shaft medical gas multifunctional control system, such as Figure 2 to Figure 9 As shown, it is applied to the connection and monitoring between the vertical shaft gas source pipeline and the shunt pipeline of each building in the hospital, including the gas pipelines corresponding to the medical oxygen, medical compressed air and medical negative pressure vacuum in the vertical shaft gas source pipeline. Medical oxygen shunt gas pipe 1, medical compressed air shunt gas pipe 2 and medical negative pressure vacuum shunt gas pipe 3, and each shunt gas pipe corresponding to medical oxygen, medical compressed air and medical negative pressure vacuum is convenient to install separately A fixed base plate 4, wherein the base plate 4 is installed on the vertical wall of the shaft space corresponding to the gas source pipeline of the shaft, and the upper side of the base plate 4 is also vertically provided with gas pipeline input corresponding to medical oxygen, medical compress...

Embodiment 2

[0054] This embodiment differs from Embodiment 1 in that, as Figure 10 and Figure 11 As shown, the medical oxygen output gas pipe connected to the secondary valve assembly 8 is also provided with a flow sensor assembly 10 installed on the bottom plate 4 to monitor the flow rate of decompressed medical oxygen. On the bottom plate 4, there is a flow display assembly 11 for displaying the flow state of medical oxygen, and on the medical oxygen output gas pipes at the front and rear ends of the flow sensor assembly 10, there are also control pipeline on-off, and flow sensor assembly maintenance and monitoring components. Close the third ball valve 12 and the fourth ball valve 13 of the entire pipeline during maintenance, and the pipelines corresponding to the third ball valve 12, the flow sensing assembly 10 and the fourth ball valve 13 are also installed in parallel on the bottom plate 4 for flow transmission. During the overhaul and maintenance of the sensor components, keep ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com