Sample preparation equipment of triaxial sample for simulating overall process erosion

A triaxial sample, whole process technology, applied in the preparation of test samples, etc., can solve the problems of low level of real force simulation of cement and soil, difficulty in triaxial sample production, etc., and achieve the effect of convenient contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

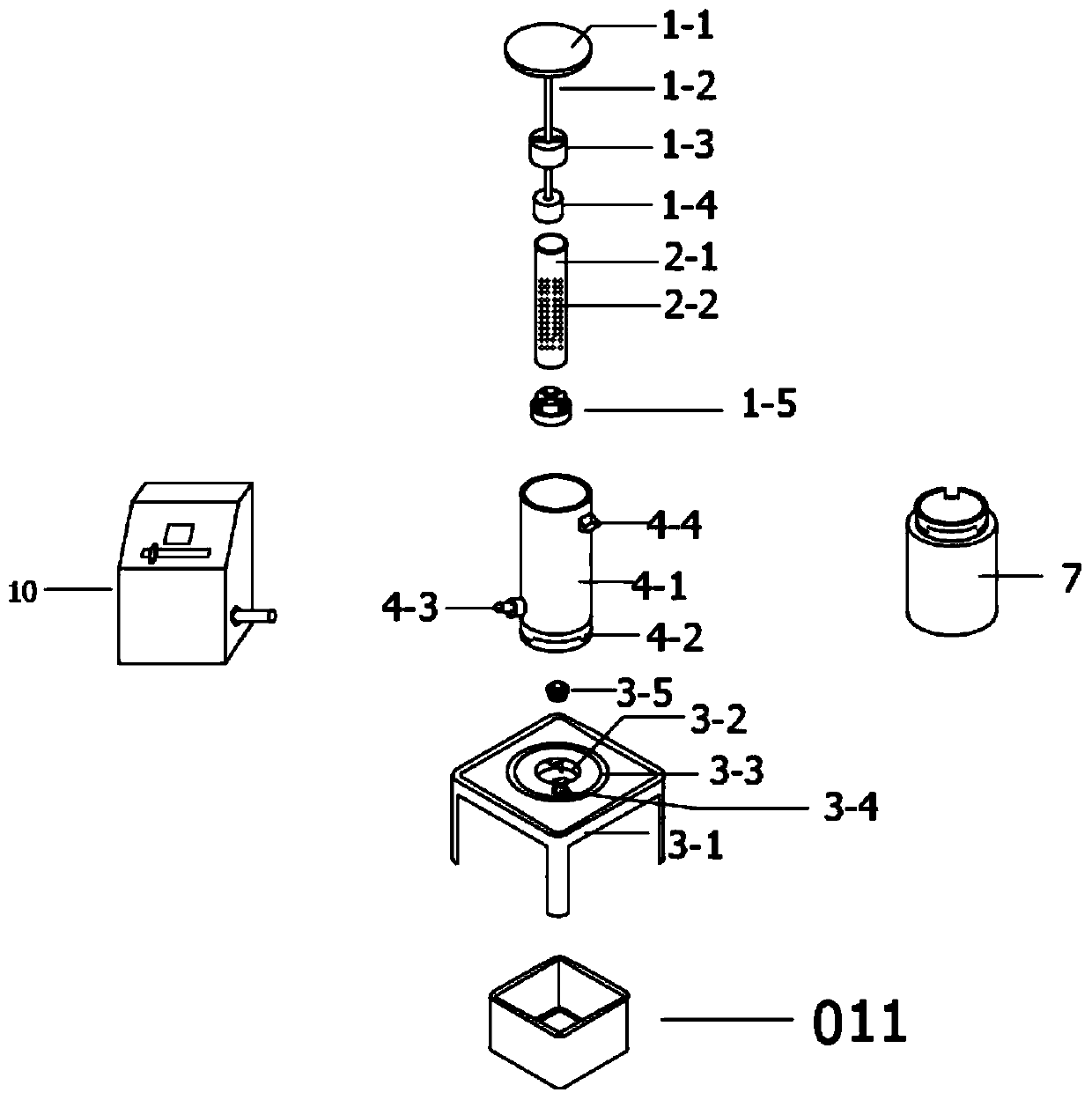

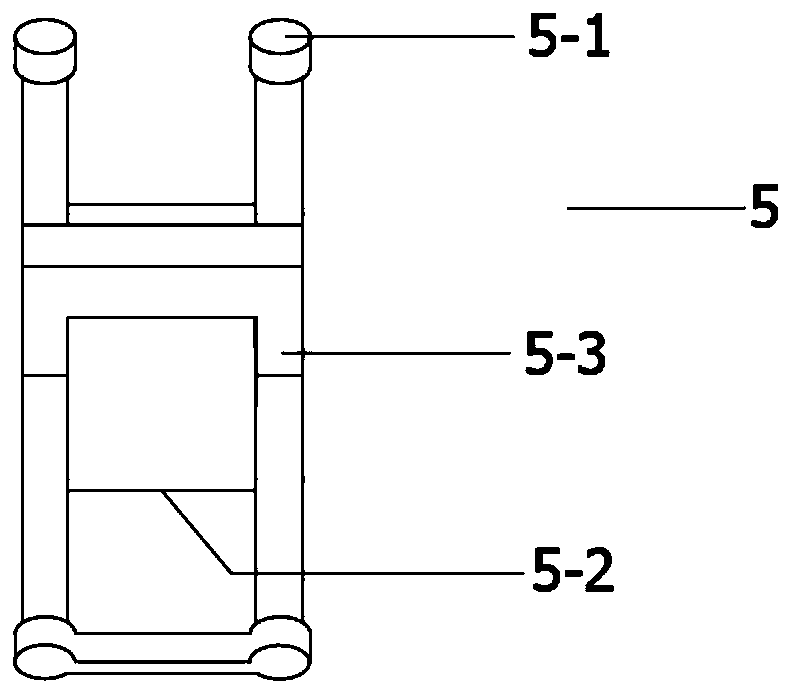

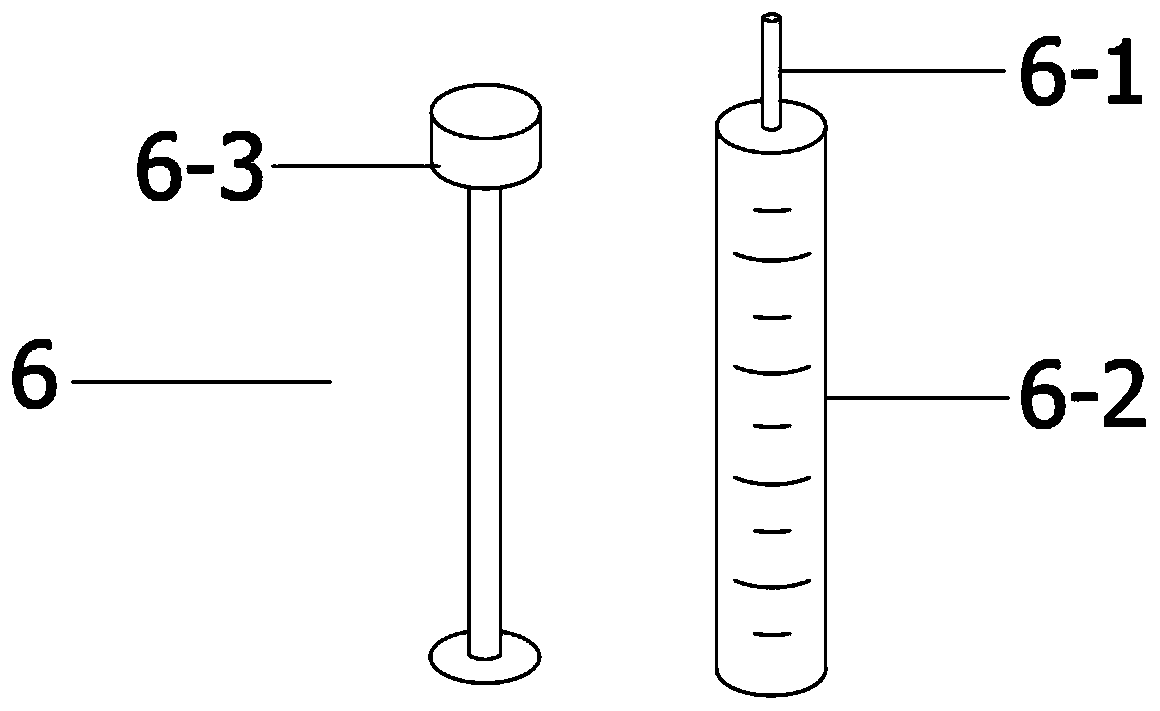

[0049] combine Figure 1-14 As shown, a sample preparation equipment for a triaxial sample that simulates the entire process of erosion in the present invention includes a pressure applying mechanism 1, a sample receiving mechanism 2, a supporting mechanism 3, an erosion mechanism 4, a cutting mechanism 5, a soil injector 6, Solution collection mechanism 7, three-bearing film cylinder 8, ear washing ball 9, electric infusion mechanism 10 and waste liquid cylinder 011.

[0050] The load-bearing plate 11 is located at the top, under which is the power transmission shaft 12, and the pressure-applying fixed cover 13 passes through the power transmission shaft 12. There are three round holes distributed on it, and the center is the power transmission shaft hole 131; Hole 132. The main body of the pressure disc 14 is a pressure cylinder 141 fixed o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com