Linear array camera and area array camera combined large-aperture super clean smooth surface defect detection device

A technology for smooth surface and defect detection, which is applied in measuring devices, optical testing of flaws/defects, and material analysis through optical means. It can solve the problems of inability to meet the requirements of detection speed, low detection efficiency and production capacity, and differences in photosensitivity. , achieve fast scanning speed, increase industrial production output, and detect sensitive effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Below, embodiment 1 of the present invention will use Figure 1-7 to describe in detail.

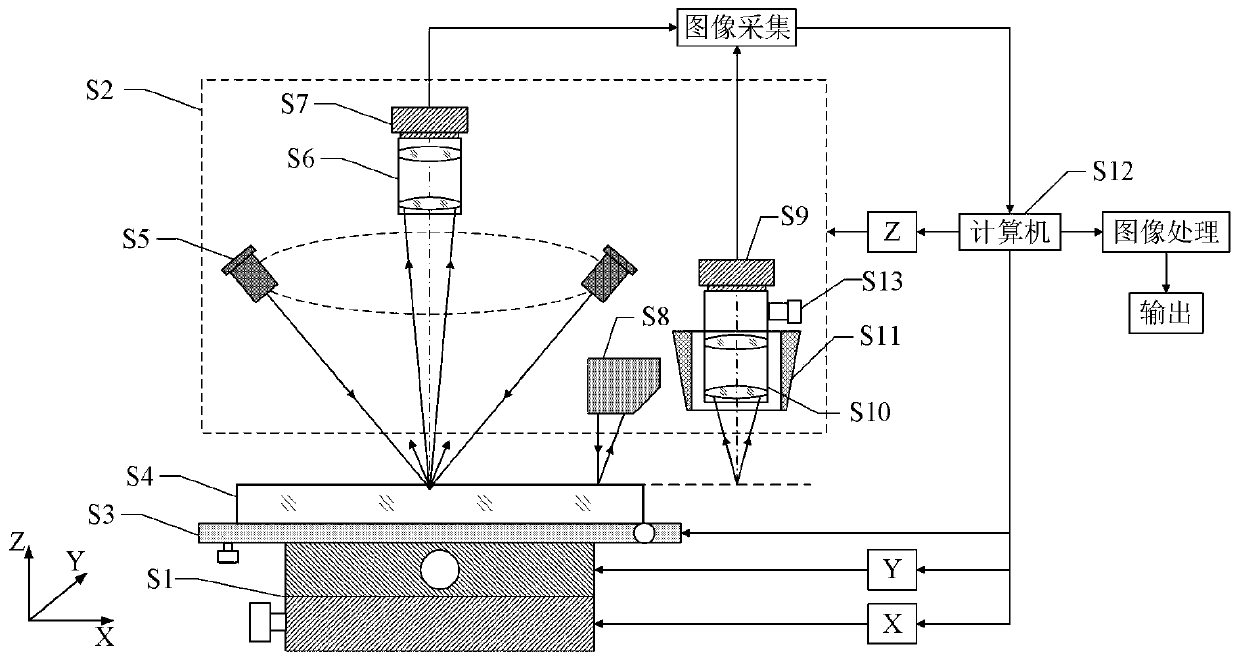

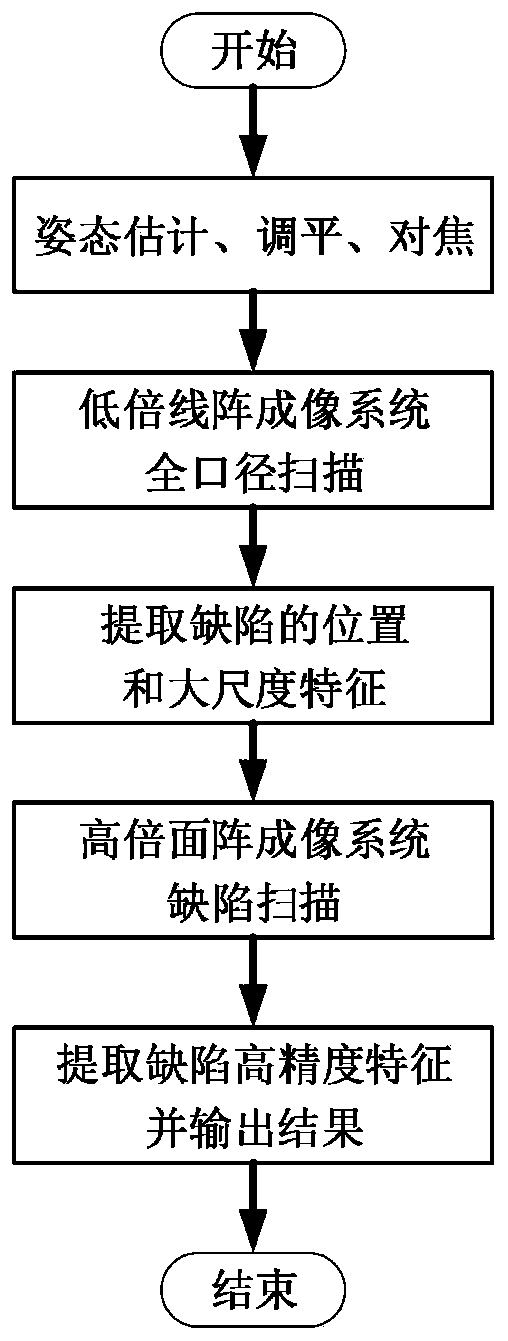

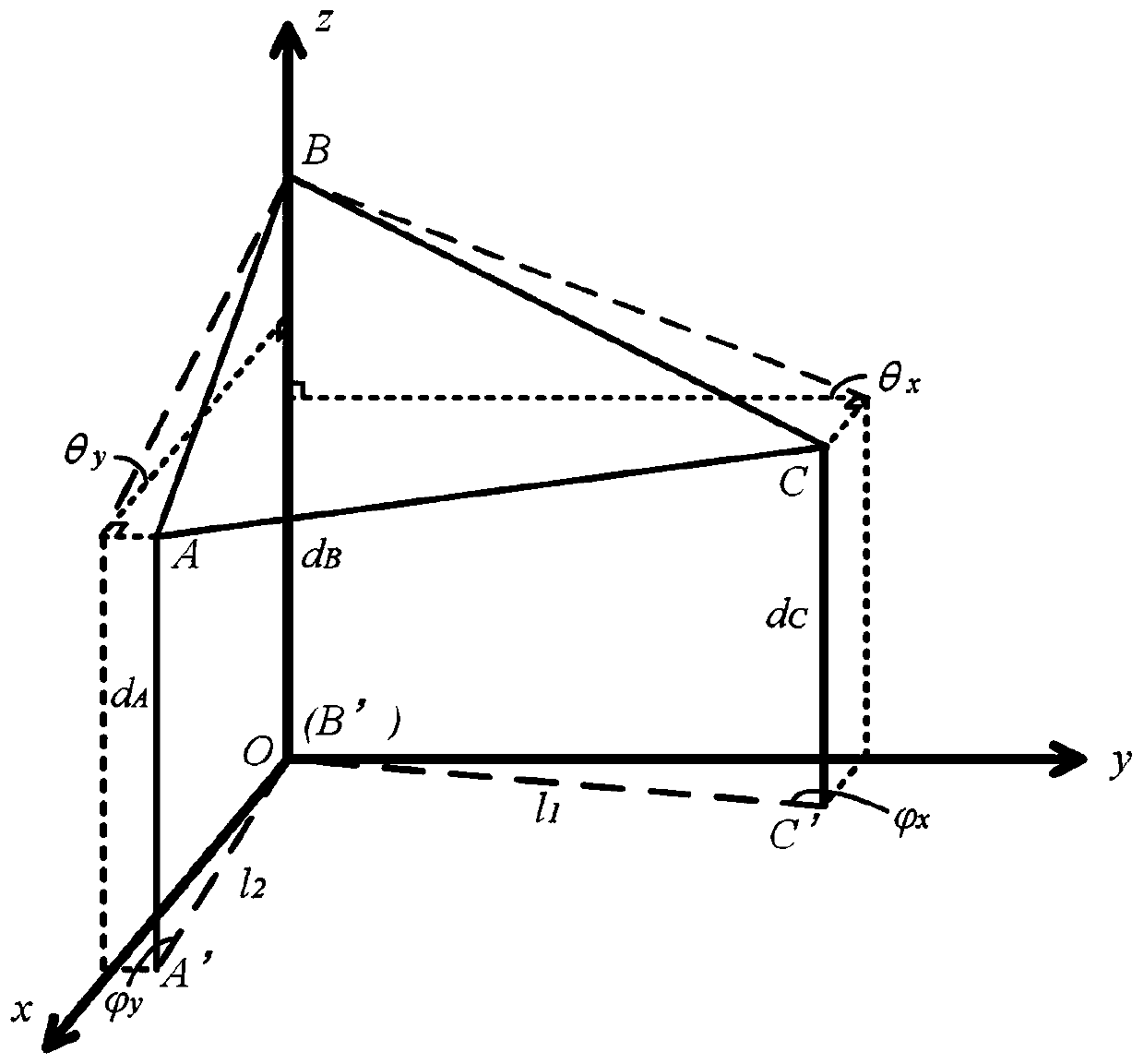

[0029] Such as figure 1As shown, a large-caliber ultra-clean smooth surface defect detection device combined with a line array camera, including a low-magnification linear array imaging system, a high-magnification area array imaging system, a distance sensing system S8, an XY two-dimensional guide rail S1, and a Z guide rail S2, clamping table S3 and console S12. Among them, the low-magnification linear array imaging system is used to quickly collect defect information on large-diameter surfaces. It consists of a ring-shaped illumination source S5, a low-magnification linear array lens S6, and a linear array camera S7. The magnification of the optical system is 1.4 times The ring-shaped lighting source S5 adopts multi-beams of high-brightness and high-uniform white LEDs distributed in a ring, obliquely incident on the ultra-clean smooth surface sample S4 at a specific angle, wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com