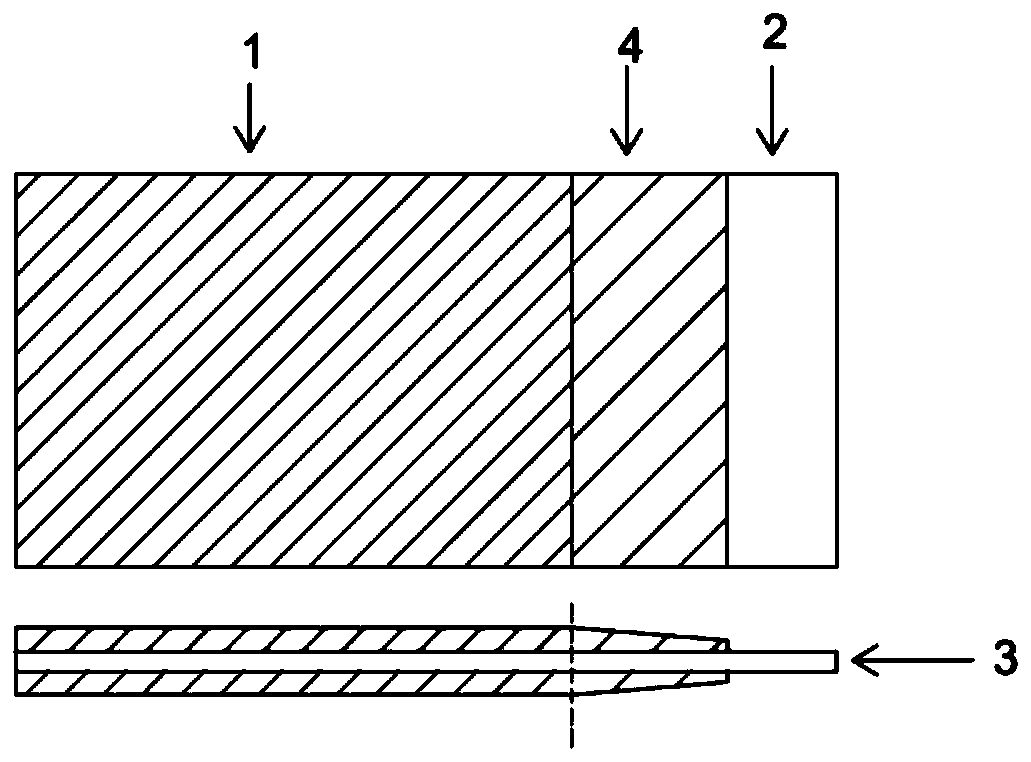

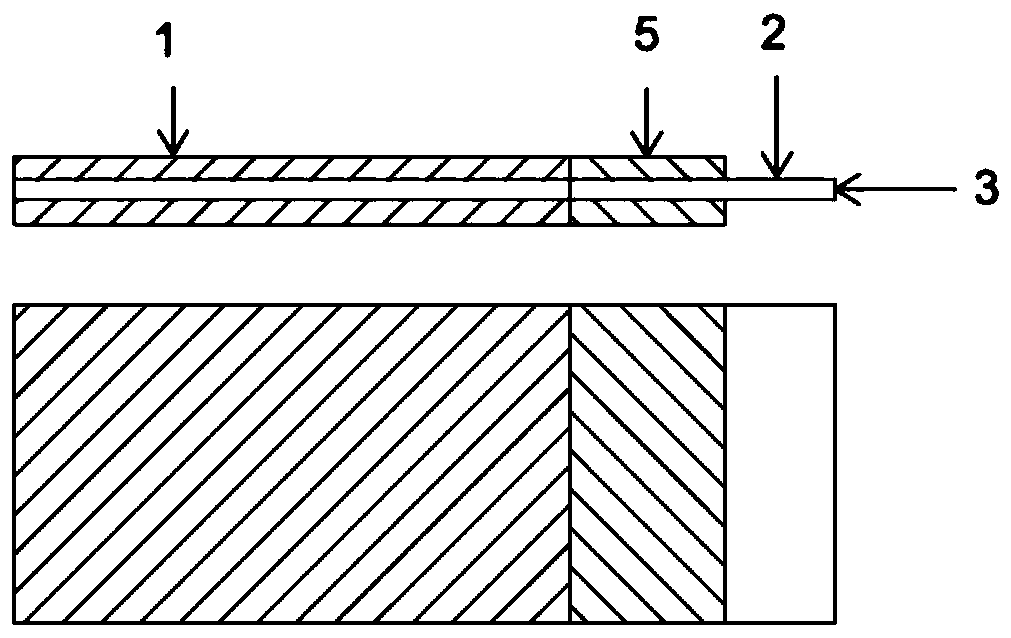

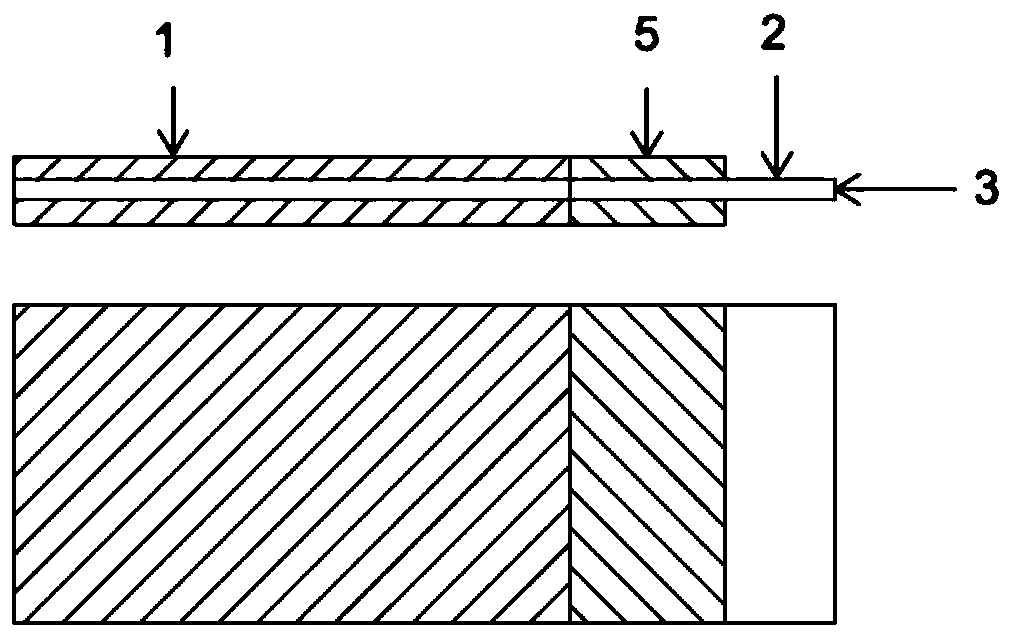

Electrode pole piece and electrochemical device comprising same

A pole piece and anode technology, applied in the field of electrochemical devices, can solve problems such as electrochemical short circuit and reduce the safety of battery cells, and achieve the effects of improving safety, improving uneven lithium deposition, and reducing the probability of lithium dendrite formation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0116] Preparation of lithium-ion batteries

[0117] The cathode active material is prepared into a lithium ion battery by the following preparation method. Specifically, the cathode active material, conductive agent, and binder are fully stirred and mixed in N-methylpyrrolidone according to a certain weight ratio to make a cathode slurry, and then the obtained cathode slurry is evenly coated on the cathode current collector The front and back surfaces of the aluminum foil are dried at 85°C to obtain a cathode active material layer, and then cold pressed, stripped, cut into pieces, and cathode tabs are welded to obtain a cathode sheet.

[0118] Fully stir and mix the anode active material, binder, and dispersant in deionized water according to a certain weight ratio to make an anode slurry, and then evenly coat the anode slurry on the front and back of the anode current collector copper foil , and then dried at 85°C to form an anode active material layer, and then perform col...

Embodiment 1-4 and comparative example 1-4

[0126] Examples 1-4 involved zone coating the cathode pole piece without zone coating the anode pole piece. The following will specifically describe the preparation method of the cathode sheet in Examples 1-4 and Comparative Examples 1-4:

[0127] The preparation method of the electrode pole piece of embodiment 1:

[0128] (1) Preparation of slurry

[0129] Negative electrode NCM811 / NCM523 slurry: Negative active ingredient NCM811 (220mAh / g) / NCM523 (180mAh / g), conductive agent Super-P and binder polyvinylidene fluoride PVDF by 97%: 1.5%: 1.5% by weight Proportionally mixed and diluted with an appropriate amount of N-methylpyrrolidone, then stirred in a vacuum mixer to form a uniform cathode slurry.

[0130] Anode graphite slurry: mix positive active component graphite, binder styrene-butadiene rubber SBR and dispersant carboxymethyl cellulose CMC in a 97%:1%:2% weight ratio, and dilute with an appropriate amount of distilled water, and then mix in a vacuum mixer Stir to for...

Embodiment 5-7 and comparative example 5-6

[0153] Examples 5-7 and Comparative Examples 5-6 only involve zone coating on the anode pole piece, but not zone coating on the cathode pole piece. The following will specifically describe the preparation method of the anode sheet in Examples 5-7 and Comparative Examples 5-6:

[0154] The preparation method of the electrode pole piece of embodiment 5:

[0155] (1) Preparation of slurry

[0156] Anode graphite / GNS slurry: positive active component graphite (370mAh / g) / GNS (740mAh / g), binder styrene-butadiene rubber SBR and dispersant carboxymethyl cellulose CMC according to 97%:1%:2% Mixed in proportion by weight, diluted with appropriate amount of distilled water, and then stirred in a vacuum mixer to form a uniform anode slurry.

[0157] Cathode NCM811 slurry: mix the cathode active component NCM811 (220mAh / g), the conductive agent Super-P and the binder polyvinylidene fluoride PVDF in a ratio of 97%:1.5%:1.5% by weight, and add an appropriate amount of NCM Diluted with bas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com