Charging device for high-power group charging system

A charging device, high-power technology, applied in charging stations, coupling devices, electric vehicle charging technology, etc., can solve the problems of fewer outlets, fewer car gas station outlets, limited car gas station space, etc., to extend service life, weight The effect of small size and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

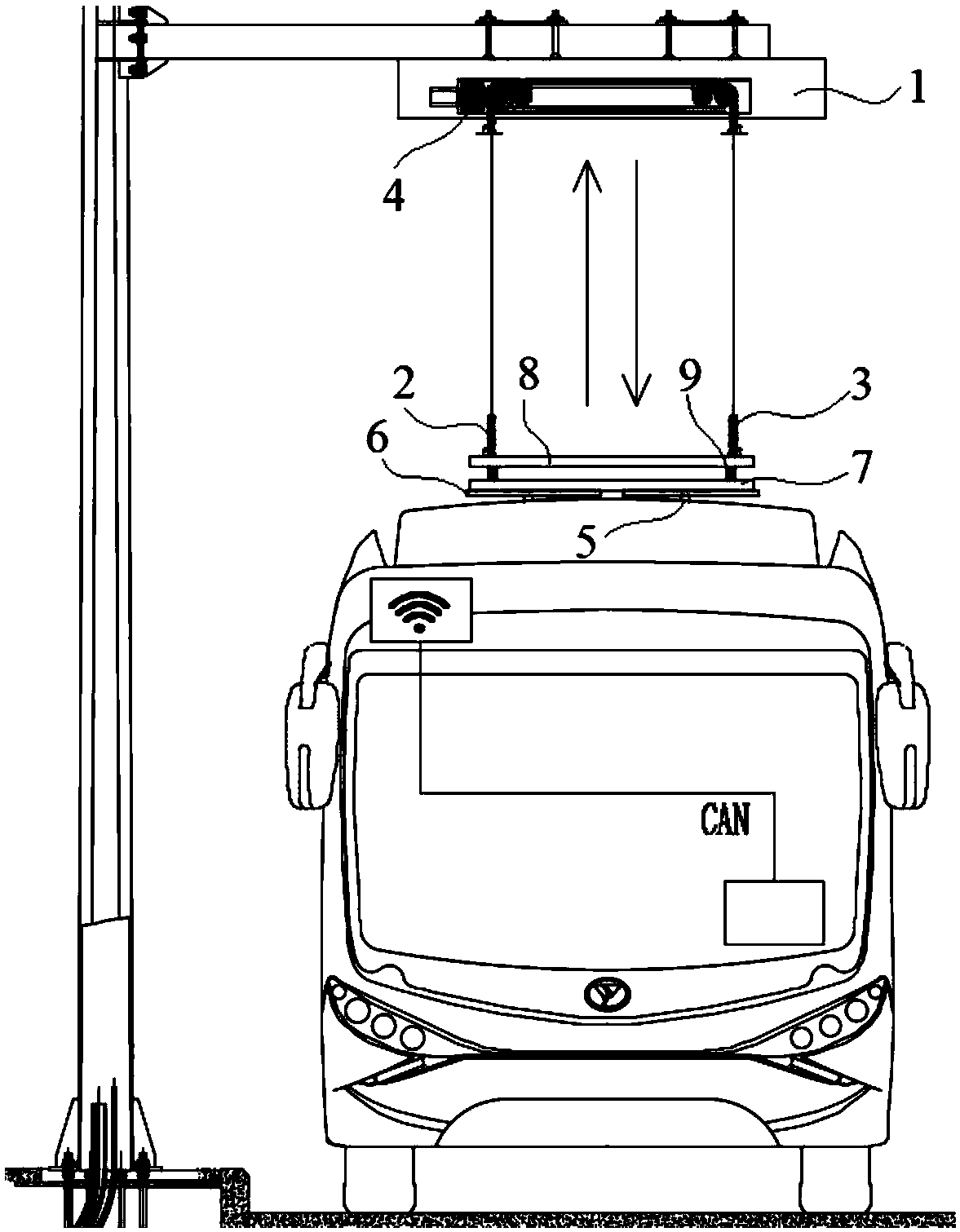

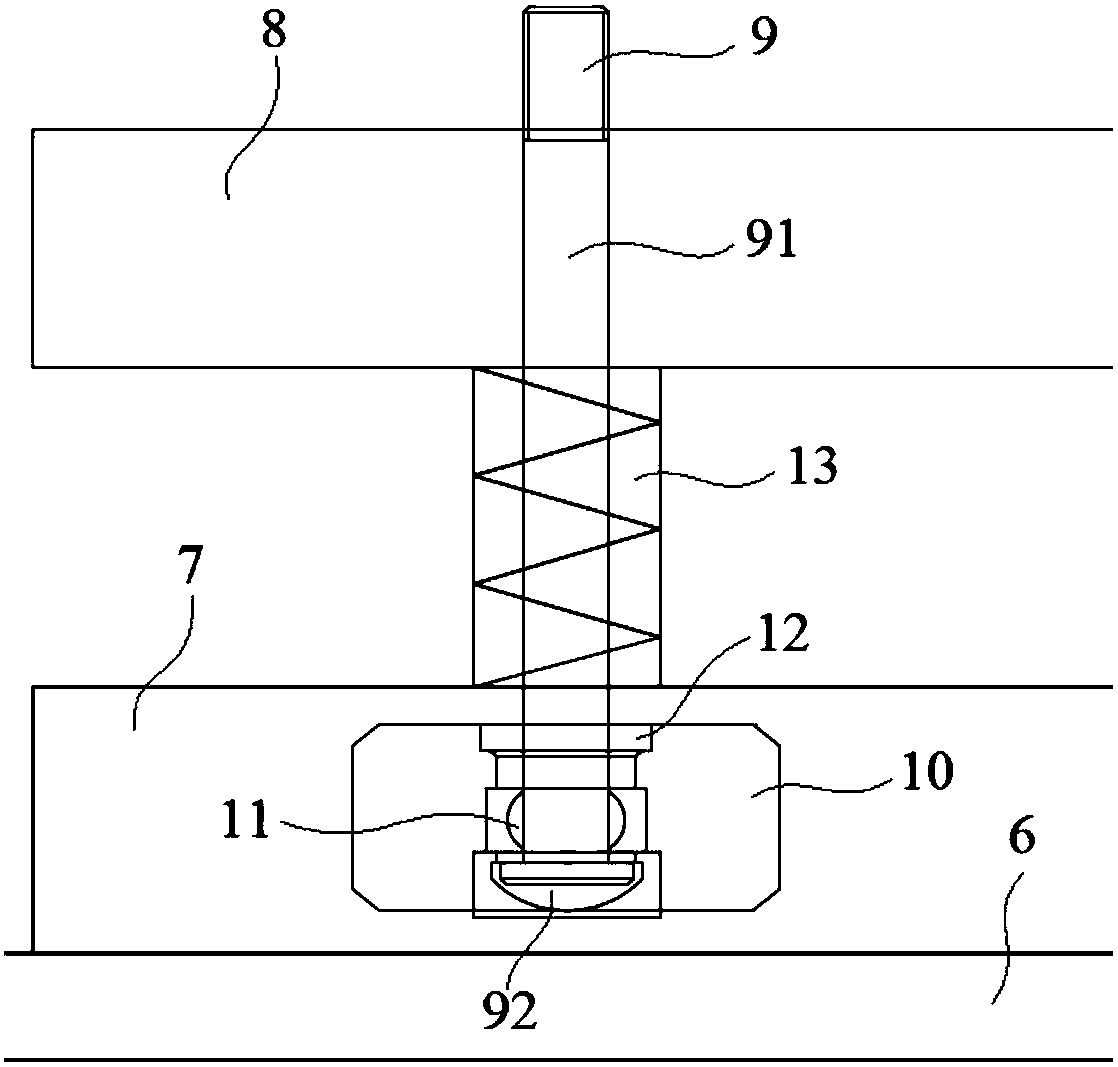

[0027] Embodiment 1: A charging device for a high-power group charging system, including a chain warehouse 1, a left support chain 2 and a right support chain 3 arranged in the chain warehouse 1, a support chain drive mechanism 4 and an electrode for receiving the vehicle roof. The charging pole 6 in contact with 5, the supporting chain driving mechanism 4 is located in the chain warehouse 1 and connected with the upper ends of the left supporting chain 2 and the right supporting chain 3 respectively, and is used to drive the left supporting chain 2 and the right supporting chain 3 to move up and down. The lower ends of the left support chain 2 and the right support chain 3 are installed and connected to the charging pole 6, and the charging pole 6 is connected to the left support chain 2 and the right support chain 3 through a mounting plate 7;

[0028]The lower ends of the left support chain 2 and the right support chain 3 are respectively fixedly connected with a fixed plate...

Embodiment 2

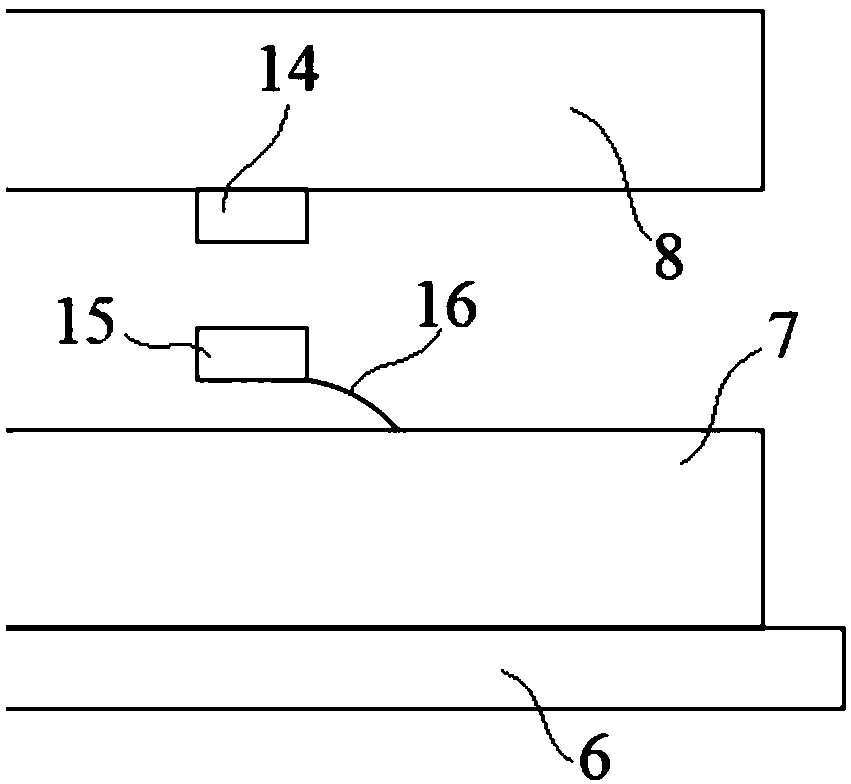

[0031] Embodiment 2: A charging device for a high-power group charging system, including a chain warehouse 1, a left support chain 2 and a right support chain 3 arranged in the chain warehouse 1, a support chain drive mechanism 4 and an electrode for receiving the vehicle roof. The charging pole 6 in contact with 5, the supporting chain driving mechanism 4 is located in the chain warehouse 1 and connected with the upper ends of the left supporting chain 2 and the right supporting chain 3 respectively, and is used to drive the left supporting chain 2 and the right supporting chain 3 to move up and down. The lower ends of the left support chain 2 and the right support chain 3 are installed and connected to the charging pole 6, and the charging pole 6 is connected to the left support chain 2 and the right support chain 3 through a mounting plate 7;

[0032] The lower ends of the left support chain 2 and the right support chain 3 are respectively fixedly connected with a fixed plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com