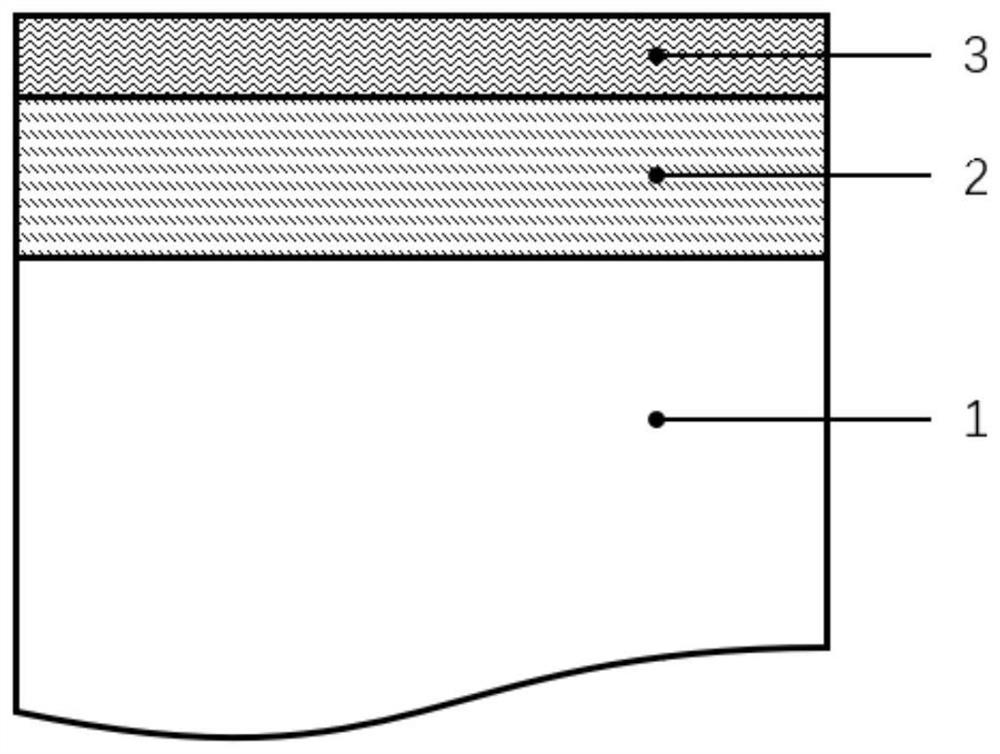

A self-lubricating tool with atomic layer deposition soft and hard composite coating and its preparation method

A technology of atomic layer deposition, soft-hard composite, applied in the direction of coating, metal material coating process, gaseous chemical plating, etc., can solve the problems of short action time, easy wear of tools, thin thickness, etc. Enhanced lubrication efficiency, high consistency and continuity, reduced cutting force and cutting temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Base material: W 18 Cr 4 V high-speed steel tool; surface self-lubricating soft coating material: MoS 2 Coating, Hard Coating Material: Nano Al 2 o 3 coating.

[0024] The preparation method of this soft and hard composite coating self-lubricating cutter is as follows:

[0025] (1) Pretreatment: Place the tool in alcohol and acetone solutions for ultrasonic cleaning for 25 minutes each for degreasing treatment; then place the tool in a plasma cleaning machine and perform plasma cleaning on its surface for 5 minutes.

[0026] (2) Deposition of Al 2 o 3 Coating: Put the cleaned tool in the ALD equipment and heat it to 420°C, alternately feed Al(CH) 3 and H 2 O precursor for Al deposition 2 o 3 coating, the pulse times of the two precursors were 0.5 s and 0.5 s, respectively. N for 30 s after the end of each precursor pulse 2 cleaning. Two of the precursors were at room temperature, and the carrier gas flow rate of the precursors was 50 sccm. After completing...

Embodiment 2

[0029] Base material: W 6 Mo 5 Cr 4 V 2High-speed steel tool; surface self-lubricating soft coating material: WS 2 Coating, Hard Coating Material: Nano Al 2 o 3 coating.

[0030] The preparation method of this soft and hard composite coating self-lubricating cutter is as follows:

[0031] (1) Pre-treatment: place the tool in alcohol and acetone solutions for ultrasonic cleaning for 15 minutes each for degreasing treatment; then place the tool in a plasma cleaning machine and perform plasma cleaning on its surface for 3 minutes.

[0032] (2) Deposition of Al 2 o 3 Coating: Place the cleaned tool in the ALD equipment and heat it to 390°C, alternately injecting Al(CH) 3 and H 2 O precursor for Al deposition 2 o 3 coating, the pulse times of the two precursors were 0.3s and 0.6s, respectively. N for 45 s after the end of each precursor pulse 2 cleaning. Two of the precursors were at room temperature, and the carrier gas flow rate of the precursors was 70 sccm. Afte...

Embodiment 3

[0035] Base material: YG6 cemented carbide; surface self-lubricating soft coating material: MoS 2 Coating, Hard Coating Material: Nano Al 2 o 3 coating.

[0036] The preparation method of this soft and hard composite coating self-lubricating cutter is as follows:

[0037] (1) Pretreatment: Place the tool in alcohol and acetone solutions for 10 minutes of ultrasonic cleaning for degreasing treatment; then place the tool in a plasma cleaning machine and perform plasma cleaning on its surface for 1 minute.

[0038] (2) Deposition of Al 2 o 3 Coating: Put the cleaned tool in the ALD equipment and heat it to 350°C, and alternately pass Al(CH) 3 and H 2 O precursor for Al deposition 2 o 3 coating, the pulse times of the two precursors were 0.1s and 0.1s, respectively. N for 20 s after the end of each precursor pulse 2 cleaning. Two of the precursors were at room temperature, and the carrier gas flow rate of the precursors was 30 sccm. After completing 2000 ALD cycles, 0....

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com