A kind of preparation method of polyacrylonitrile graphene fiber

A graphene fiber, polyacrylonitrile technology, applied in spinning solution preparation, fiber chemical characteristics, rayon manufacturing and other directions, can solve problems such as insufficient fiber performance, and achieve the effect of improving performance and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

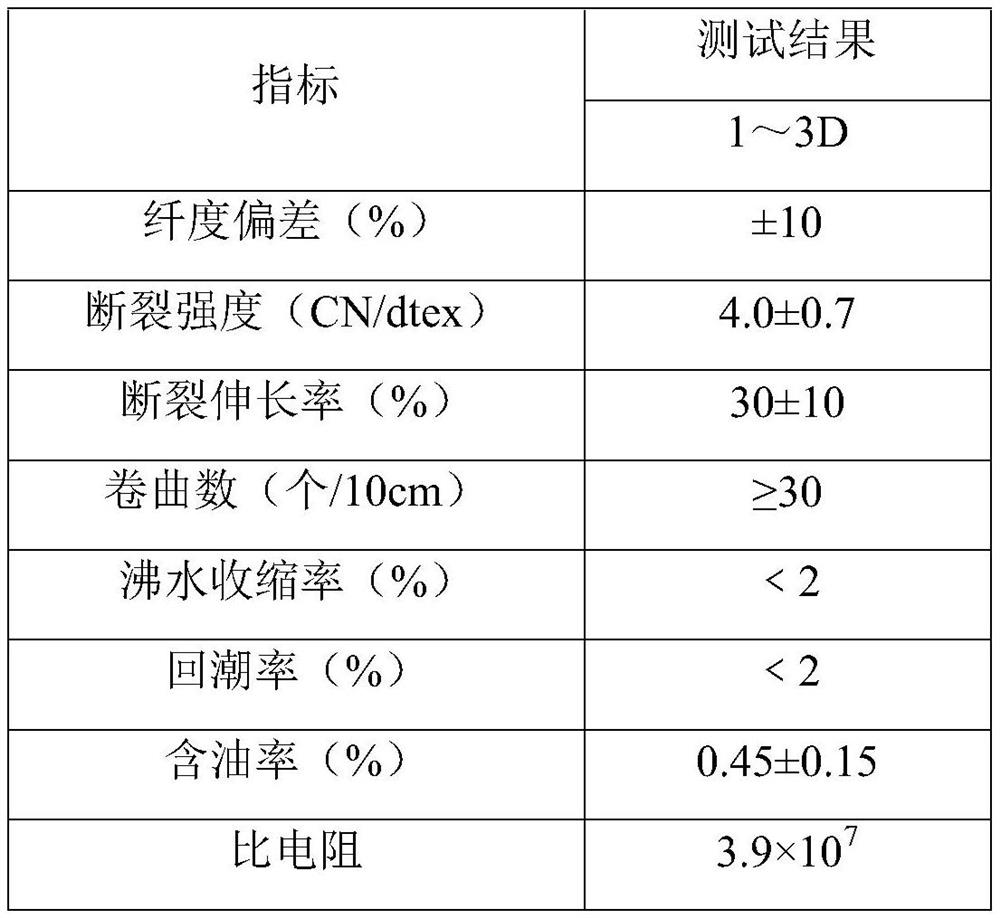

Image

Examples

Embodiment 1

[0041] (1) With a concentration of 90.5wt% acrylonitrile and a concentration of 5.75wt% vinyl acetate as monomers, the monomer concentration is 15wt%, and at a temperature of 50°C and a pH of 2.5, carry out aqueous phase suspension polymerization , to obtain polyacrylonitrile powder; after mixing polyacrylonitrile powder with dimethylacetamide, first heating up and then cooling down to obtain polyacrylonitrile solution;

[0042] (2) Grinding the graphene to a particle size of less than 10 μm and mixing it with dimethylacetamide and polyacrylonitrile solution to obtain a graphene mother liquor, wherein the concentration of graphene is 6wt%;

[0043] (3) Graphene mother liquor is mixed with polyacrylonitrile solution, and the ratio of graphene mother liquor and polyacrylonitrile solution is 2:100, obtains spinning solution;

[0044] (4) The spinning solution is spun by a two-step wet spinning process, wherein the coagulation bath is dimethylacetamide, the concentration of the co...

Embodiment 2

[0046] (1) With a concentration of 90.5wt% acrylonitrile and a concentration of 5.75wt% vinyl acetate as monomers, the monomer concentration is 15wt%, and at a temperature of 50°C and a pH of 2.5, carry out aqueous phase suspension polymerization , to obtain polyacrylonitrile powder; after mixing polyacrylonitrile powder with dimethylacetamide, first heating up and then cooling down to obtain polyacrylonitrile solution;

[0047] (2) Grinding the graphene to a particle size of less than 10 μm and mixing it with dimethylacetamide and polyacrylonitrile solution to obtain a graphene mother liquor, wherein the concentration of graphene is 6wt%;

[0048] (3) Graphene mother liquor is mixed with polyacrylonitrile solution, and the ratio of graphene mother liquor and polyacrylonitrile solution is 10:100, obtains spinning solution;

[0049] (4) The spinning solution is spun by a two-step wet spinning process, wherein the coagulation bath is dimethylacetamide, the concentration of the c...

Embodiment 3

[0051] (1) With a concentration of 90.5wt% acrylonitrile and a concentration of 5.75wt% vinyl acetate as monomers, the monomer concentration is 15wt%, and at a temperature of 50°C and a pH of 2.5, carry out aqueous phase suspension polymerization , to obtain polyacrylonitrile powder; after mixing polyacrylonitrile powder with dimethylacetamide, first heating up and then cooling down to obtain polyacrylonitrile solution;

[0052] (2) Grinding graphene to a particle size of less than 10 μm and mixing with dimethylacetamide and polyacrylonitrile solution to obtain a graphene mother liquor, wherein the concentration of graphene is 20wt%;

[0053] (3) Graphene mother liquor is mixed with polyacrylonitrile solution, and the ratio of graphene mother liquor and polyacrylonitrile solution is 20:100, obtains spinning solution;

[0054] (4) The spinning solution is spun by a two-step wet spinning process, wherein the coagulation bath is dimethylacetamide, the concentration of the coagula...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com