Method and device for detecting thickness of film

A technology for detecting thin films and thin films, applied in measuring devices, instruments, using wave/particle radiation, etc., can solve problems such as inability to measure, unsuitable for measuring metal and alloy thin films, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

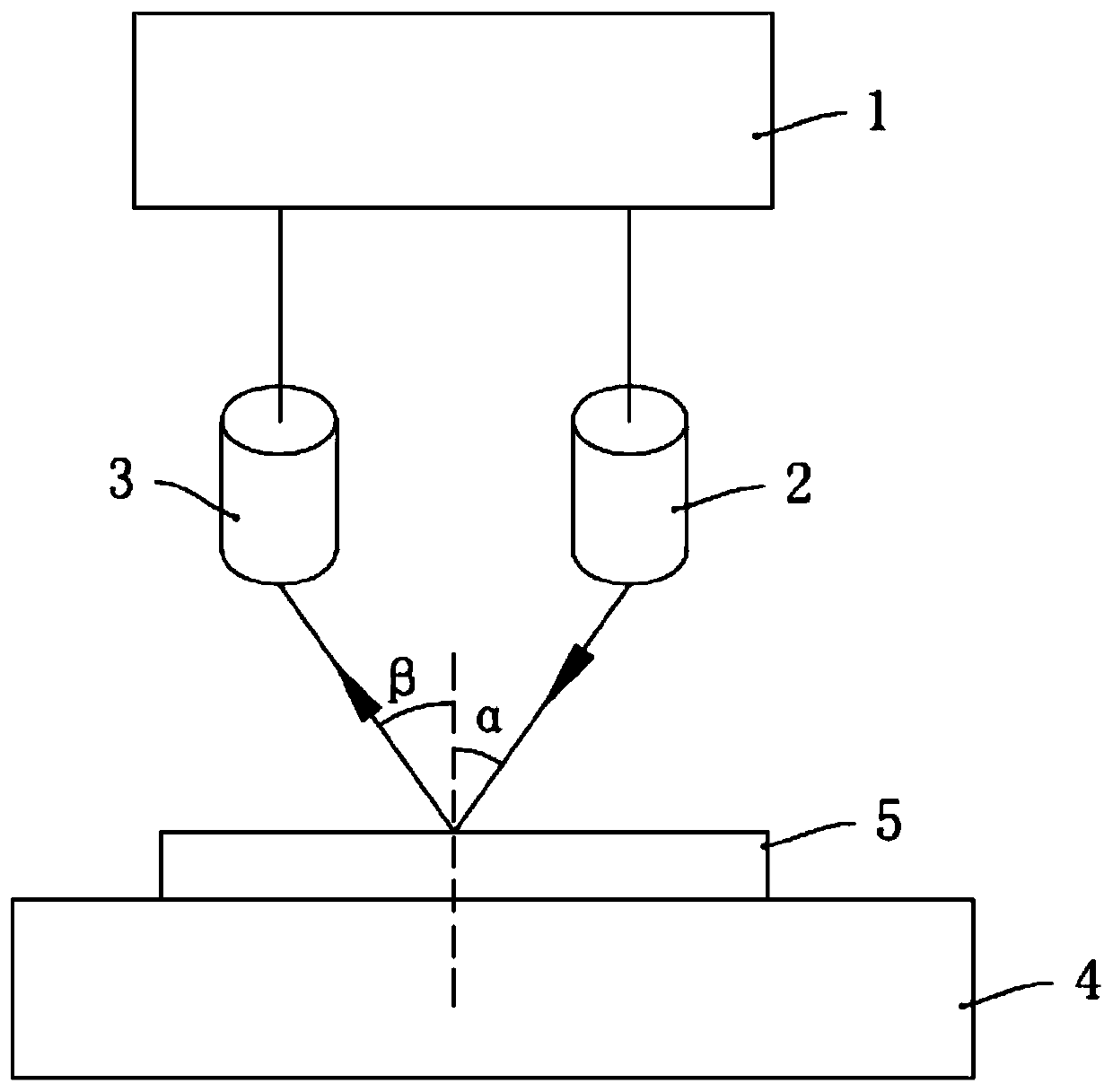

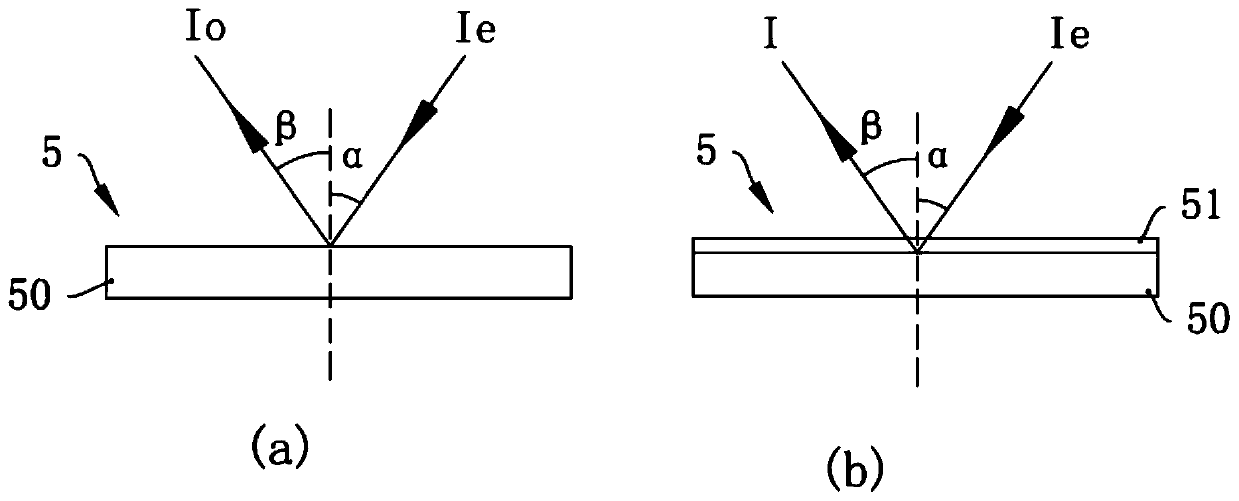

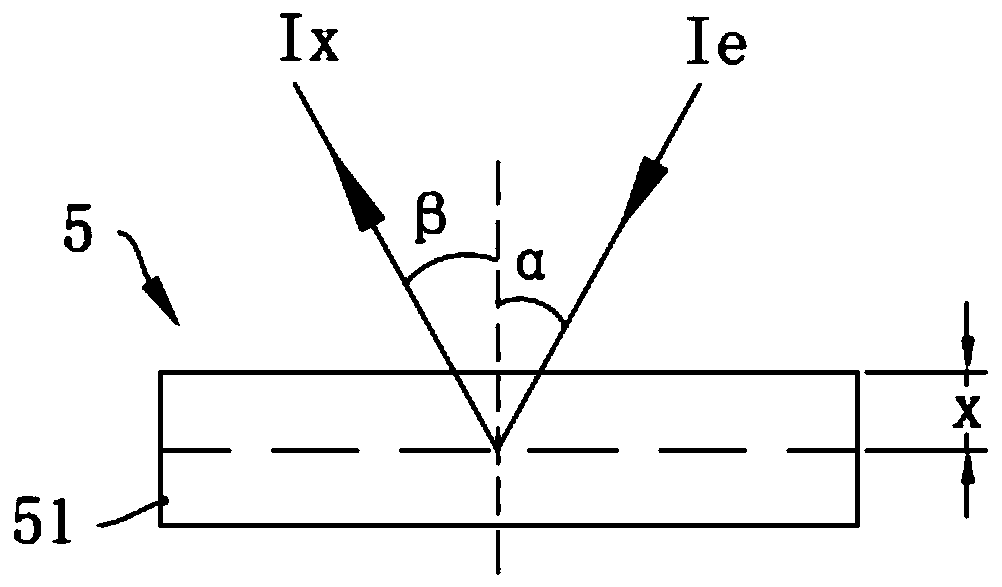

[0070] Embodiment 1 Substrate signal attenuation method

[0071] Place the silicon substrate without film deposition and the samples deposited with aluminum films of different thicknesses on the test platform 4 respectively, and keep the ambient air pressure lower than 5×10 -4 Pa, the electron beam generating device 2 generates electron beams to project on each sample in turn, the energy of the electron beam is 2keV, and the beam current is 50nA, and the detection device 3 obtains the EDS energy spectrum of each sample, as Figure 4 shown. The X-ray fluorescence characteristic energy corresponding to the substrate Si element is 1.739keV. Such as Figure 5 As shown, with the increase of Al film thickness, the intensity of X-ray fluorescence characteristic energy corresponding to Si element decreases gradually.

[0072] For the substrate Si signal, the intensity exhibits an exponential decay characteristic with the increase of Al film thickness. Exponential fitting (implemen...

Embodiment 2

[0074] Embodiment 2 thin film signal enhancement method

[0075] Place the silicon substrate without film deposition and the samples deposited with aluminum films of different thicknesses on the test platform 4 respectively, and keep the ambient air pressure lower than 5×10 -4 Pa, the electron beam generating device 2 generates electron beams to project on each sample in turn, the energy of the electron beam is 2keV, the beam current is 50nA, and the detection device 3 obtains the X-ray fluorescence energy spectrum corresponding to the Al element whose characteristic energy of each sample is 1.485keV ,Such as Figure 4 shown. As the thickness of the Al film increases, the intensity of the X-ray fluorescence characteristic energy corresponding to the Al element increases gradually.

[0076] For the Al signal in thin films, the intensity shows an exponential increase characteristic with the increase of Al film thickness, see Figure 7 . Exponential fitting (implemented in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com