Integrated circuit protection structure and manufacturing method thereof

A technology for protecting structures and integrated circuits, applied in circuits, electrical components, electrical solid devices, etc., can solve problems such as affecting the process, failure to fill the upper layer of conductive via holes, invalid protection structures, etc., and achieve the effect of preventing damage or peeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

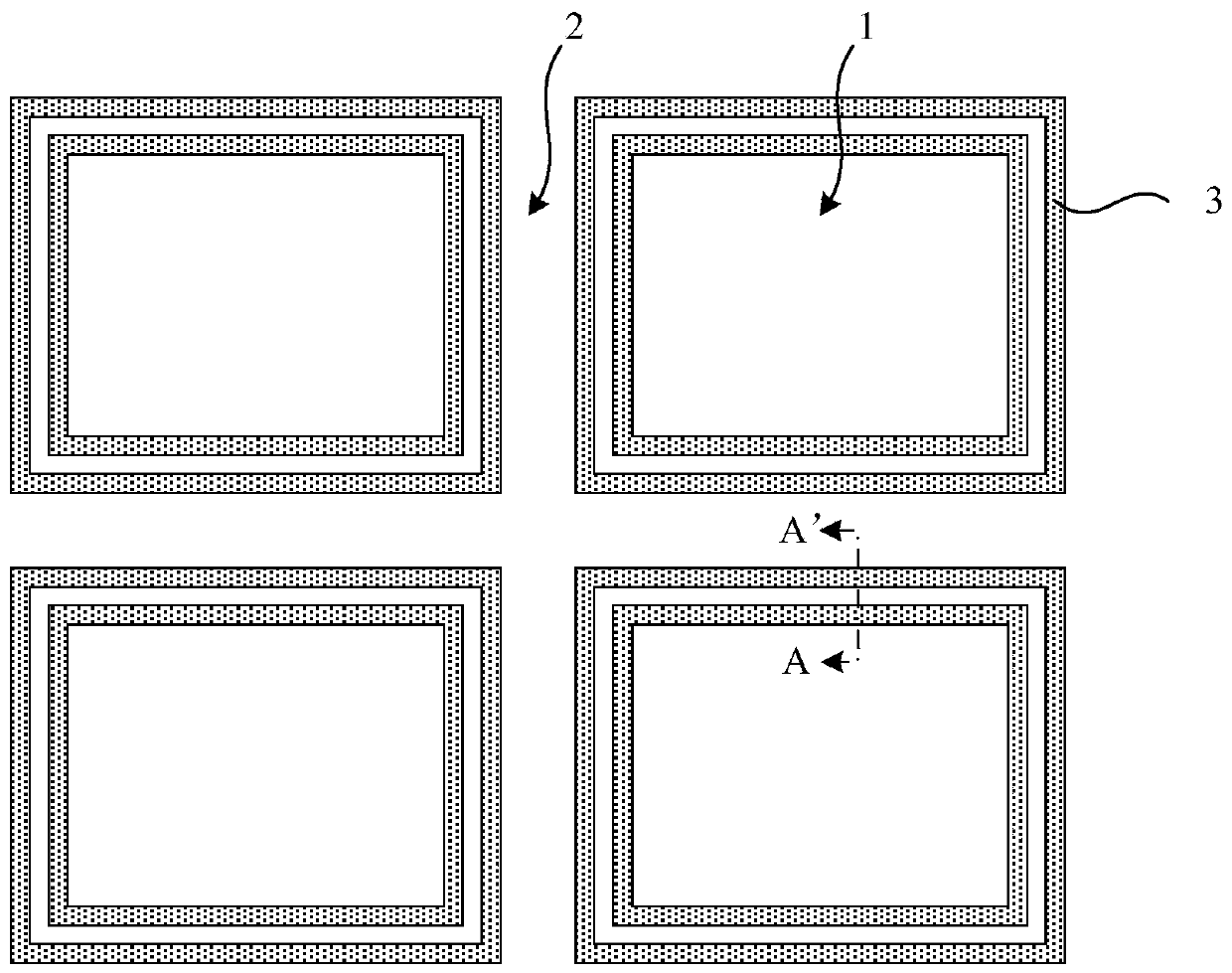

[0067] In this embodiment, the sealing ring is taken as an example to illustrate the integrated circuit protection structure of the present invention. In other embodiments, the integrated circuit protection structure may also be a protection ring or other protection structures.

[0068] see Figure 4 , shown as the A-A' direction of the seal ring structure (see figure 1 The cross-sectional view indicated by the two-way arrow in the center), in which, figure 1 Each set of sealing rings only shows two ring structures, while Figure 4 The ellipsis in represents that the number of ring structures in the seal ring structure is not limited to two rings, and can be more.

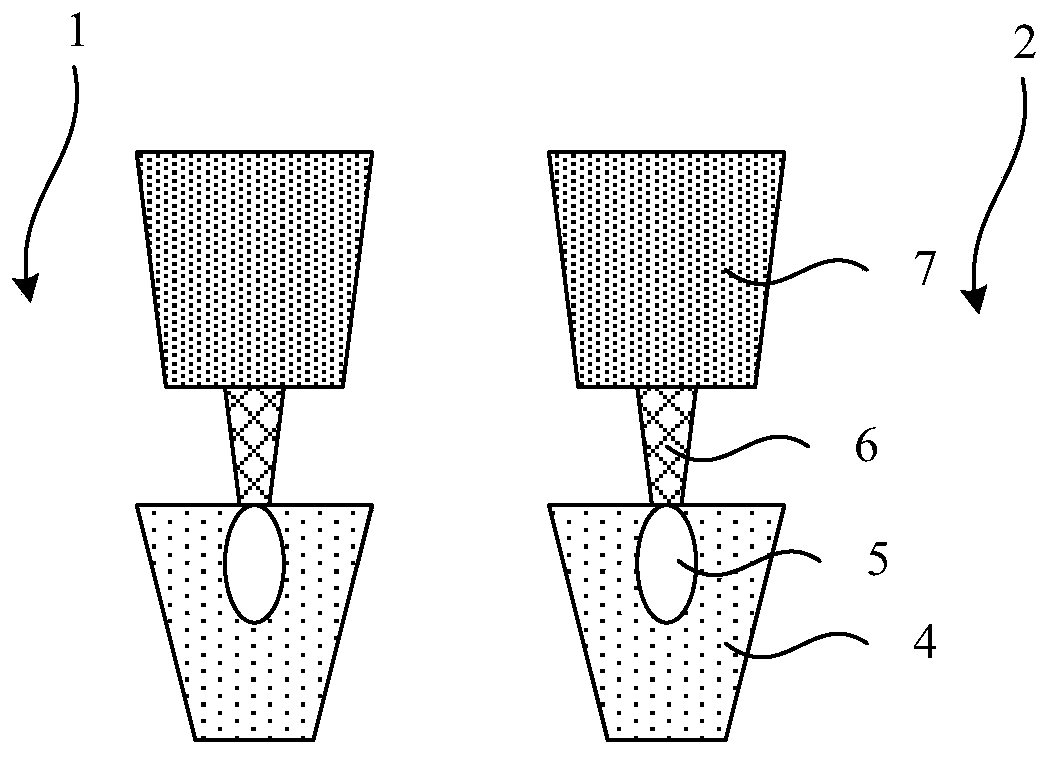

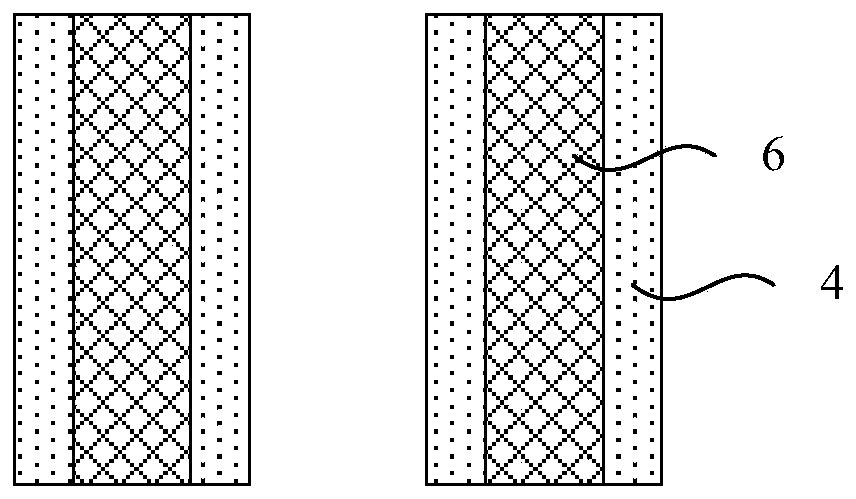

[0069] Specifically, the annular structure includes a first interconnection layer, a via layer and a second interconnection layer, wherein the first interconnection layer includes at least one conductive portion 4, and the via layer includes at least one conductive portion 4. A via 6, the conductive via 6 is con...

Embodiment 2

[0079] This embodiment adopts basically the same technical solution as that of Embodiment 1, the difference is that in Embodiment 1, the conductive vias deviate from the center of the lower conductive part toward the inner side of the annular structure, while in this embodiment, each The conductive via holes of the ring structure are all deviated from the center of the lower conductive portion 4 toward the outside of the ring structure.

[0080] see Figure 6 and Figure 7 ,in, Figure 6 It is shown as an A-A' sectional view of the seal ring structure in this embodiment. Figure 7 shown as Figure 6 The relative top view of the conductive portion 4 and the conductive via 6 in the shown structure.

Embodiment 3

[0082] This embodiment adopts basically the same technical solution as that of Embodiment 1, the difference is that in Embodiment 1, the conductive vias deviate from the center of the lower conductive part towards the inner side of the annular structure, while in this embodiment, at least One of the conductive vias 6 of the annular structure deviates from the center of the lower conductive part 4 toward the inner side of the annular structure, and at least one of the conductive vias 6 of the annular structure goes toward the inner side of the annular structure. The outer direction of the outer layer deviates from the center of the lower layer conductive part 4 .

[0083] see Figure 8 and Figure 9 , it is shown that the conductive via hole 6 of the inner ring structure deviates from the center of the lower conductive part 4 toward the outer direction of the ring structure, and the conductive through hole 6 of the outer ring structure deviates toward the inner direction of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com