Formula and production technology of gentle moistening super fruit-flavored yogurt

A production process and super technology, applied in dairy products, milk preparations, applications, etc., can solve the problems of unable to achieve the expected taste, ineffective urinary health and intestinal maintenance, weak acidity, etc., to achieve better product flavor, prevent Urinary tract infection problems, the effect of preventing septicemia

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

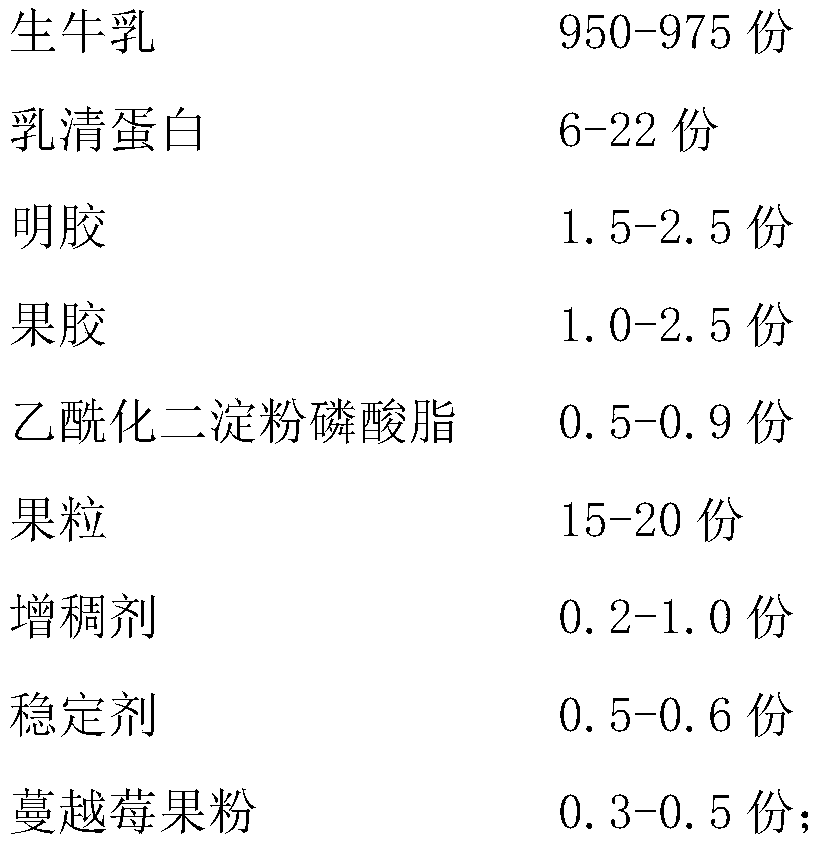

[0033] A formula and production process of light moist super fruit-flavored yoghurt, wherein the formula raw materials include:

[0034]

[0035]

[0036] Described production process comprises the following steps:

[0037] S1. Raw milk, whey protein, gelatin, pectin and acetylated distarch phosphate are mixed according to the weight component ratio to obtain sample A;

[0038] S2. Sample B is obtained by mixing fruit particles, thickener, cranberry fruit powder and natural vitamin C, wherein the thickener is selected from starch, which is a conventional material, so it is easy to obtain and low in cost;

[0039] S3, 90% of sample A and 10% of sample B are mixed and filled.

[0040] Specifically, the specific steps for mixing the raw materials of sample A in the above step S1 are as follows:

[0041] a. Flash steaming raw milk at 50°C;

[0042] b. Add whey protein powder to the raw milk treated in step a, and hydrate at 45°C for 55 minutes;

[0043] c. Chemically tre...

Embodiment 2

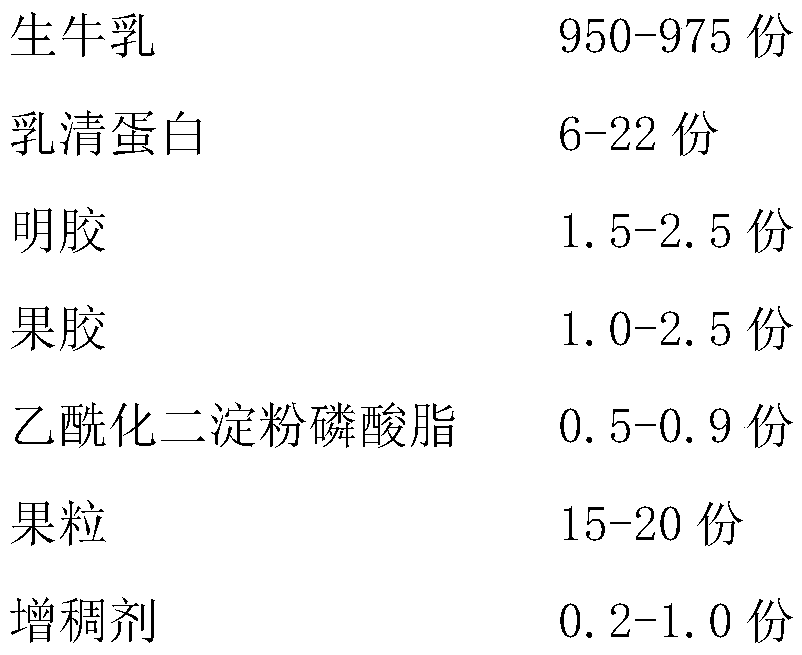

[0051] A formula and production process of light moist super fruit-flavored yoghurt, wherein the formula raw materials include:

[0052]

[0053] Described production process comprises the following steps:

[0054] S1. Raw milk, whey protein, gelatin, pectin and acetylated distarch phosphate are mixed according to the weight component ratio to obtain sample A;

[0055] S2. Sample B is obtained by mixing fruit particles, thickener, cranberry fruit powder and natural vitamin C, wherein the thickener is selected from starch, which is a conventional material, so it is easy to obtain and low in cost;

[0056] S3, 90% of sample A and 10% of sample B are mixed and filled.

[0057] Specifically, the specific steps for mixing the raw materials of sample A in the above step S1 are as follows:

[0058] a. Flash steaming raw milk at 50°C;

[0059] b. Add whey protein powder to the raw milk treated in step a, and hydrate at 50°C for 35 minutes;

[0060] c. Chemically treat gelatin, ...

Embodiment 3

[0068] A formula and production process of light moist super fruit-flavored yoghurt, wherein the formula raw materials include:

[0069]

[0070] Described production process comprises the following steps:

[0071] S1. Raw milk, whey protein, gelatin, pectin and acetylated distarch phosphate are mixed according to the weight component ratio to obtain sample A;

[0072] S2. Sample B is obtained by mixing fruit particles, thickener, cranberry fruit powder and natural vitamin C, wherein the thickener is selected from starch, which is a conventional material, so it is easy to obtain and low in cost;

[0073] S3, 90% of sample A and 10% of sample B are mixed and filled.

[0074] Specifically, the specific steps for mixing the raw materials of sample A in the above step S1 are as follows:

[0075] a. Flash steaming raw milk at 50°C;

[0076] b. Add whey protein powder to the raw milk treated in step a, and hydrate at 55°C for 20 minutes;

[0077] c. Chemically treat gelatin, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com