A polymer-based nano-lanthanum carbonate material, preparation method, application and regeneration method

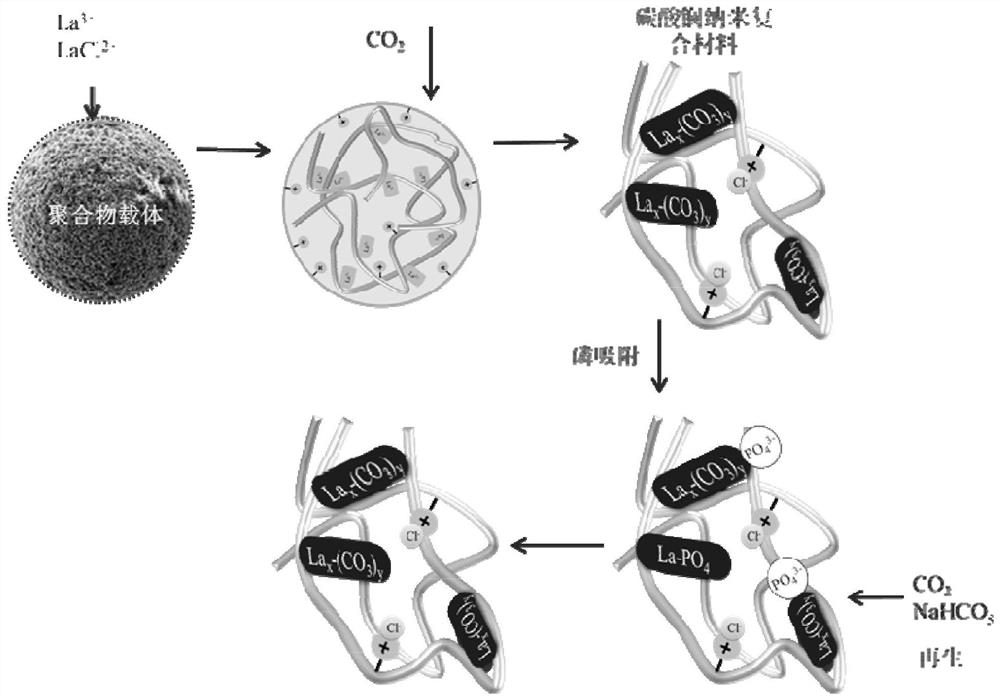

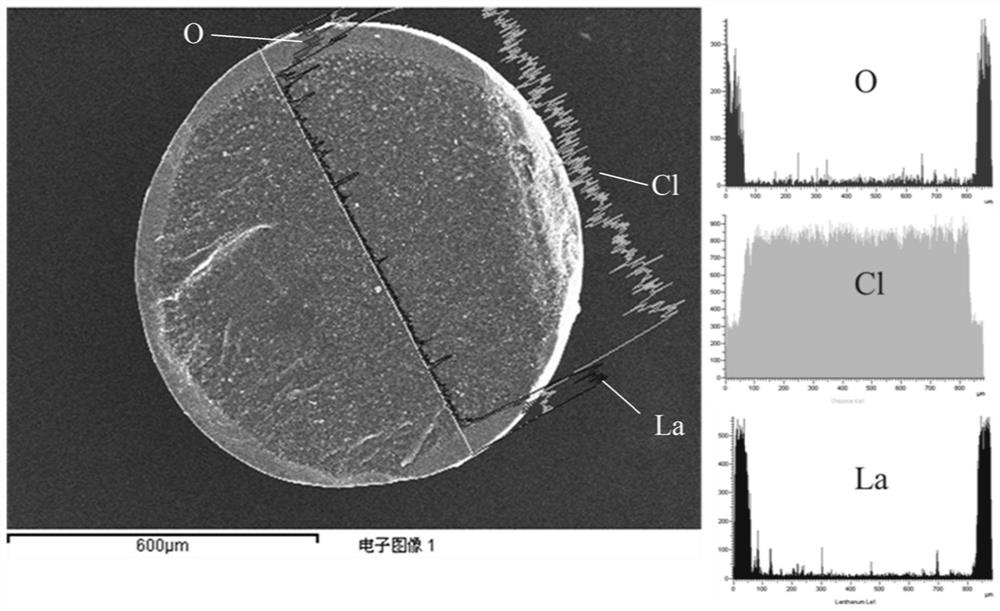

A technology of nano-carbonic acid and polymers, applied in separation methods, filter regeneration, chemical instruments and methods, etc., can solve the problems of difficult polymer-based nano-lanthanum carbonate material preparation, harsh process conditions, etc., to improve the loading capacity and dispersion degree, the effect of avoiding uncertainty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] Preparation method and application of polymer-based nanocarbon material, in fact, the form of application is:

[0060] 1) 5 g of seven water chloride is dissolved in 50 ml of ethanol and 100 ml of ultra-pure water, 10 g of chloromethylstyrene-divinylphenylene copolymer, stirred at 50 ° C for 12 h;

[0061] 2) Place the product from which step 1) is placed at 60 ° C to a solid-liquid ratio of 1000 g / L to obtain product B;

[0062] 3) Turn into the product B obtained from step 2) at 60 ° C to the compression Co 2 , CO 2 The pass rate of 50 ml / min was 30 mL / min, and the mixture was stirred at room temperature for 8 h at 60 ° C for 8 h, resulting in product C;

[0063] 4) Use 10% NaHCO at normal temperature. 3 The solution was washed with 1BV / H flow rate to wash solidification for 2 h, resulting in product D;

[0064] 5) The product D was added to 400 ml of 5% NaCl solution, stirred at room temperature until the pH of the NaCl solution supernatant was in the range of 6....

Embodiment 2

[0074] The present embodiment is a method and application of a polymer-based nanocarbon material, which is basically forth in Example 1, but also adjusts some of the parameters, still achieving the same effect. details as follows:

[0075] Concentrate in step 2) to a solid-liquid ratio of 500 g / L;

[0076] In step 3), in 50 ° C product B is introduced into CO 2 The flow rate was 20 ml / min, and the mixture was stirred at room temperature for 12 h then stirred at 50 ° C for 8 h;

[0077] Step 4) 3% NaHCO 3 The solution was lubricated in 1BV / H flow rate for 2 h;

[0078] Step 6) The resulting product was added to 200 ml of 20% ethanol water for 0.5 h, and the excess liquid was removed from 30 ° C.

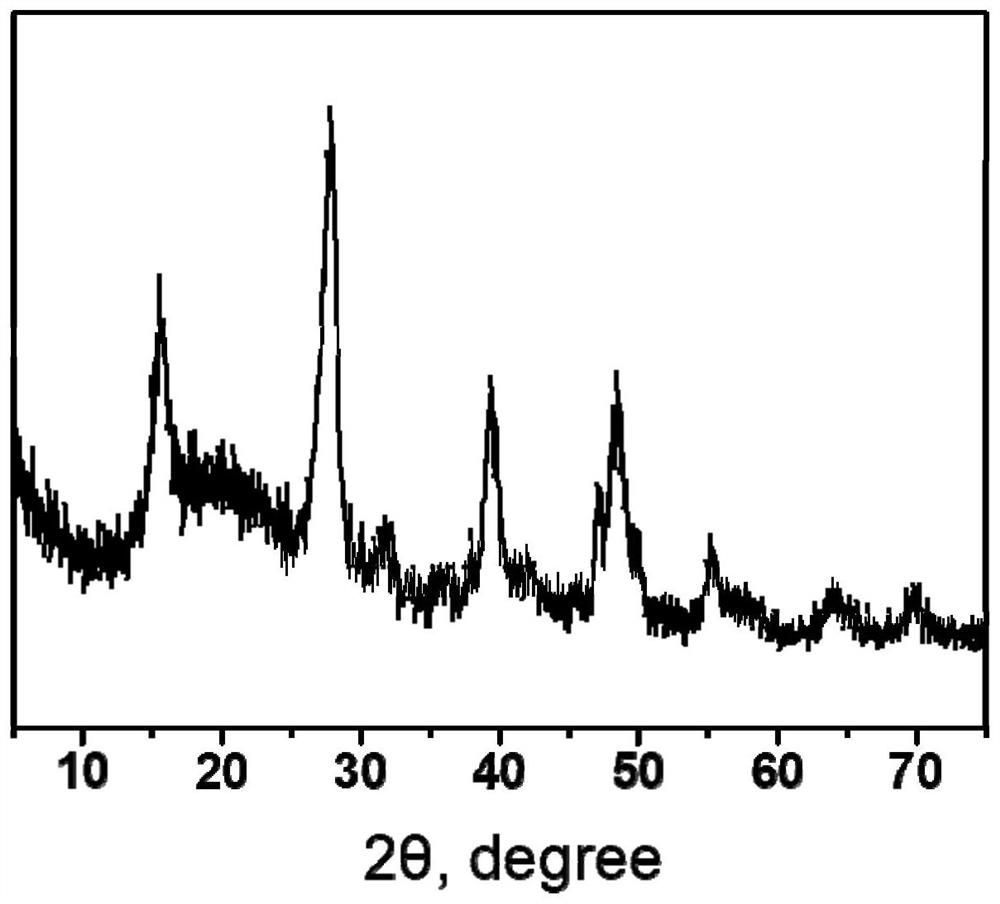

[0079] The polymer-based nanocarbon carbonate produced by this example was 10.08%; the degree of crystallinity was 30%; the particle size of nanocratic carbonate was 10 to 50 nm. The p adsorption experiment was performed in accordance with Embodiment 1 to measure the amount of P ads...

Embodiment 3

[0081] The present embodiment is a method and application of a novel polymer-based nanocarbon carbonate material. Basically, in Example 1, it is only adjusted to some parameters, and it can still achieve the same effect. details as follows:

[0082] Step 2) first concentrated at 50 ° C, then warmed to 60 ° C, concentrated to solid-liquid ratio of 700 g / L;

[0083] Step 3) Top Co in product B at 30 ° C 2 The flow rate was 60 mL / min, and stirred at room temperature for 12 h after stirring at 60 ° C for 8 h;

[0084] Step 4) 5% NaHCO 3 The solution was lubricated in 1BV / H flow rate for 2 h;

[0085] Step 6) The resulting product was added to 200 ml of 20% ethanol water to stir 0.5 h, and then dried at 40 ° C after removing excess liquid.

[0086] The polymer-based nanocarbon carbonate produced by this embodiment was 11.8%; the degree of crystallinity was 48%; the particle size of nanocratic carbonate was 10 to 50 nm. The P adsorption experiment was measured by the Method in Exa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com