DC heavy-current measuring device and measuring method

A measuring device and high-current technology, applied in the direction of measuring device, measuring electrical variables, measuring only current, etc., can solve the problems of affecting compensation current size, measurement error, measurement error amplification, etc., to achieve small measurement impact, high measurement accuracy, The effect of stable work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

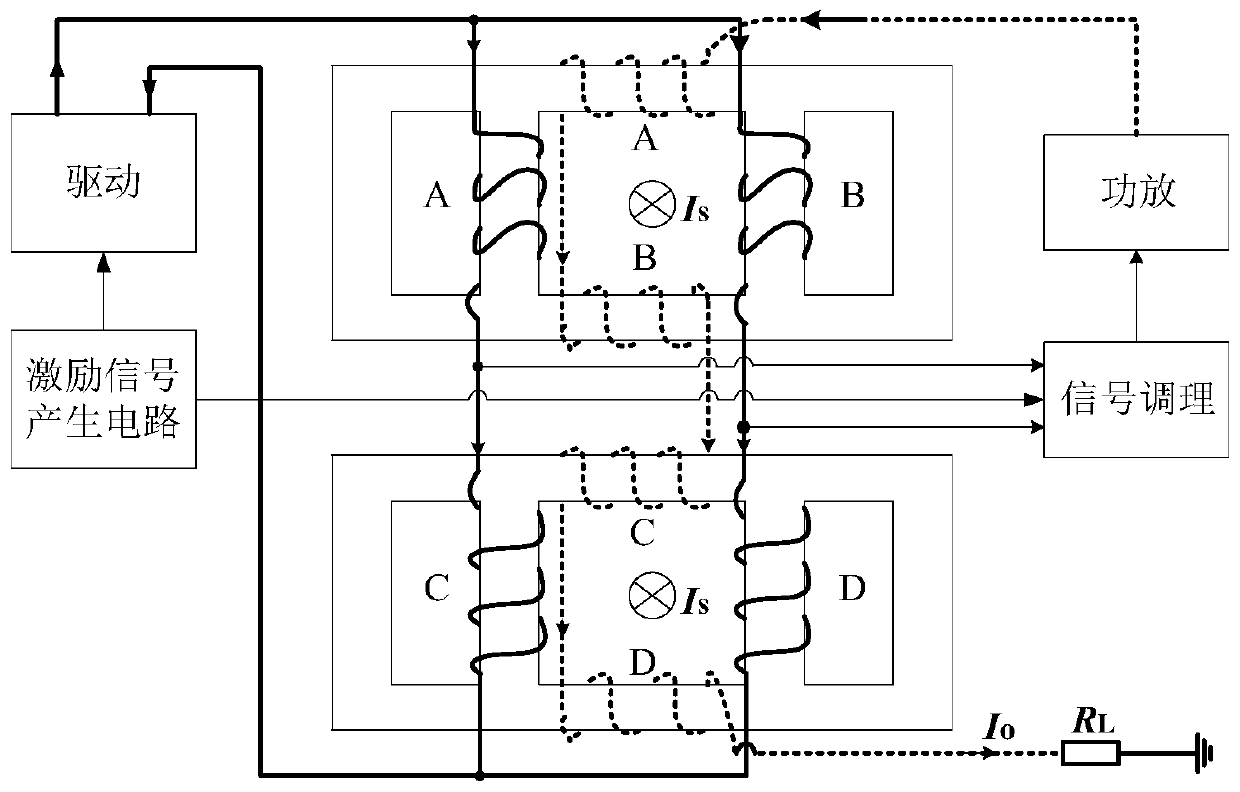

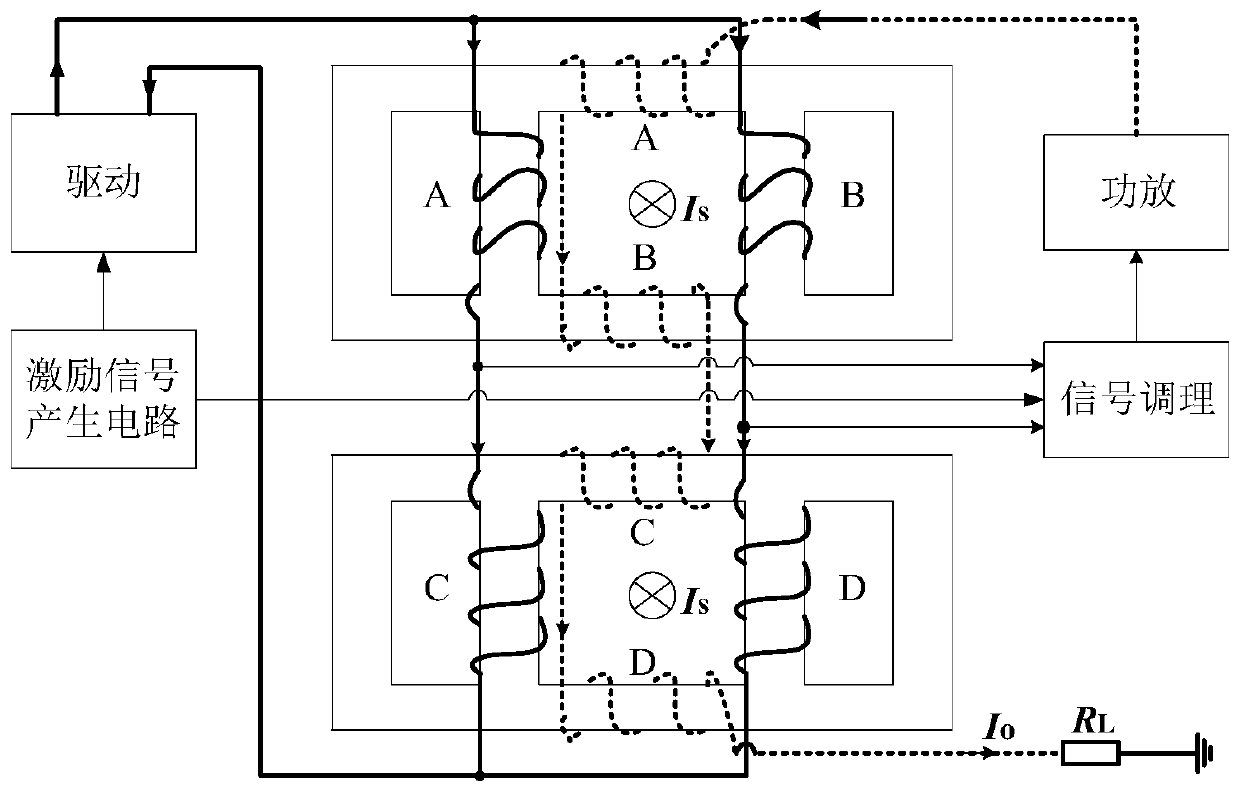

[0026] This embodiment provides a DC large current measuring device, including a four-column iron core, first, second, third, and fourth excitation windings, first, second, third, and fourth compensation windings, and an excitation signal generating circuit , drivers, signal conditioning circuits, power amplifiers and standard resistors.

[0027] There are two sets of four-column iron cores, stacked front and back, and the current to be measured passes through the holes in the middle of the two sets of iron cores. The first excitation winding A and the second excitation winding B with the same number of turns are wound on the middle two columns of the four-column iron core at the rear, and the first compensation winding A' with the same number of turns is wound on the middle two horizontal columns. And the second compensation winding B', corresponding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com