Preparation method and application of nitrogen-doped porous carbon-coated cobalt nanoparticle composite material

A nitrogen-doped porous carbon and composite material technology, applied in the field of electrochemical energy, can solve the problems of loss of active sites, weak interaction between atoms, etc., to improve stability, improve oxygen reduction performance, and protect from corrosion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] The preparation steps of the composite material of nitrogen-doped porous carbon-coated cobalt nanoparticles in this embodiment are as follows:

[0045]1. Use an electronic balance to weigh 1.245g of cobalt acetate tetrahydrate and dissolve it in 100mL of deionized water, and stir for 30min to form a transparent solution;

[0046] 2. Weigh 4.2g of dicyandiamide and add it to the solution in the above step 1, heat to 80°C at the same time, and stir until the dicyandiamine is completely dissolved to form a transparent solution;

[0047] 3. Weigh 10.5g of citric acid monohydrate, dissolve in the solution of the above step 2, and continue to stir for 6h;

[0048] 4. Evaporate the solution prepared in the above step 3 to dryness at 120°C;

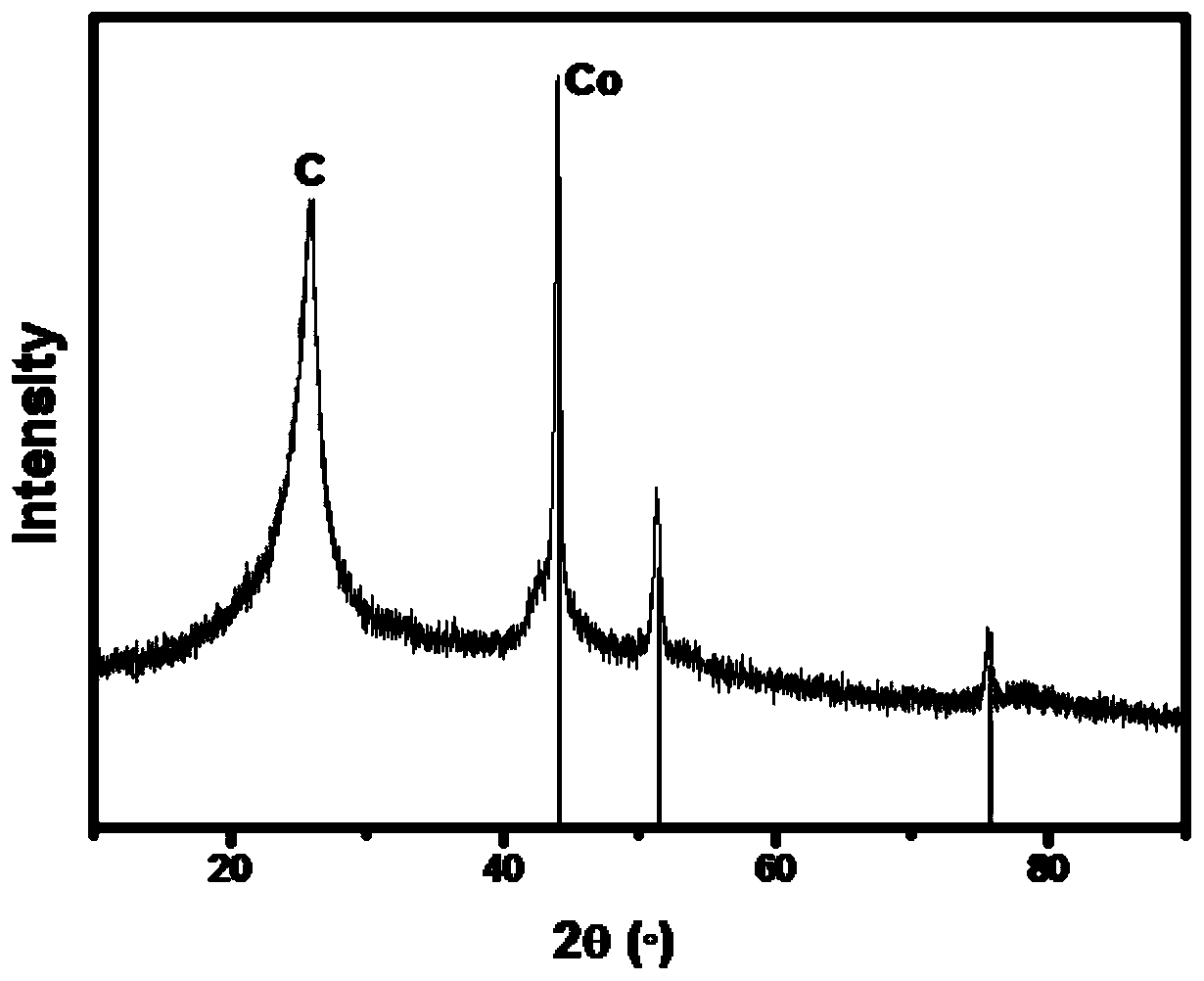

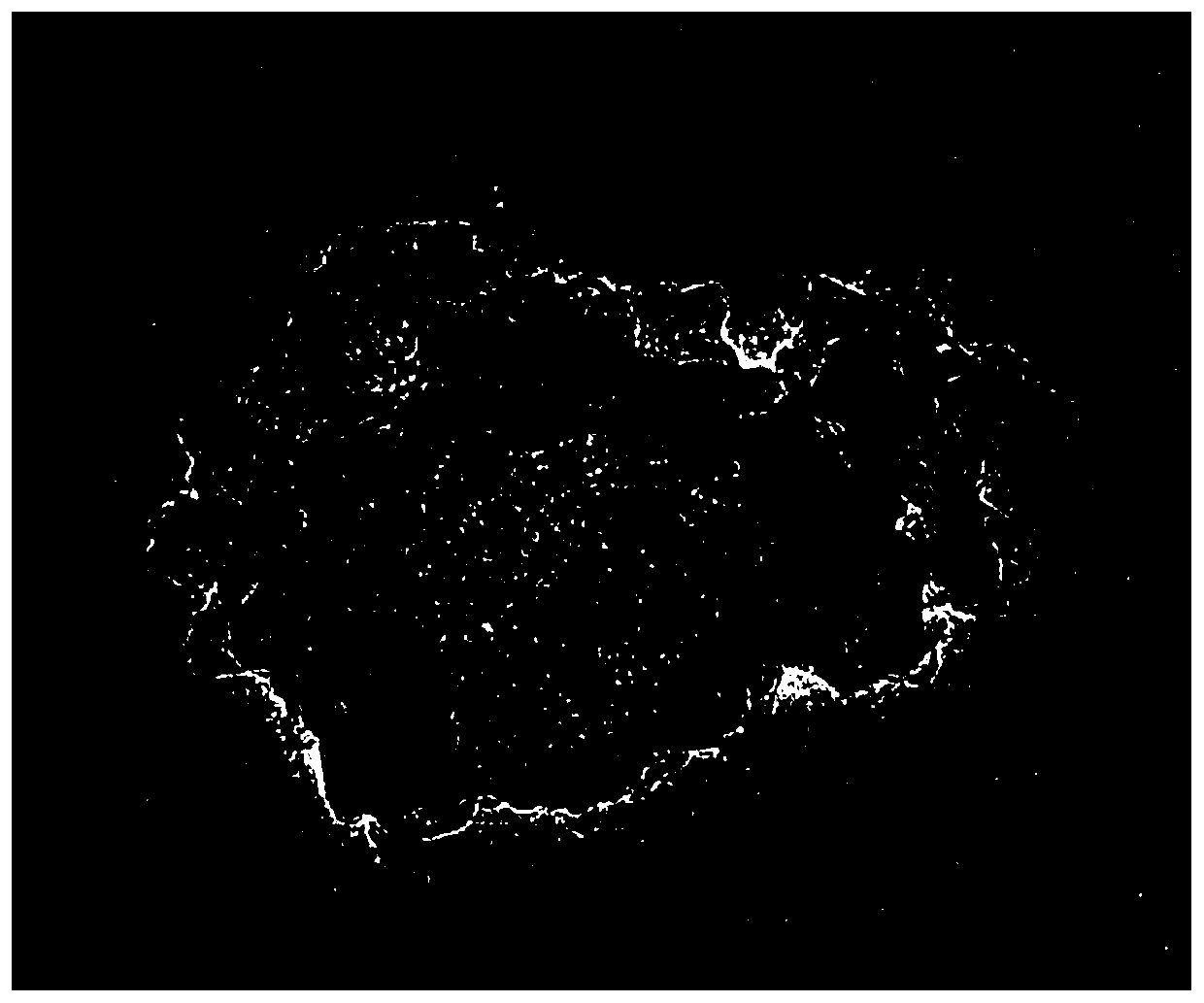

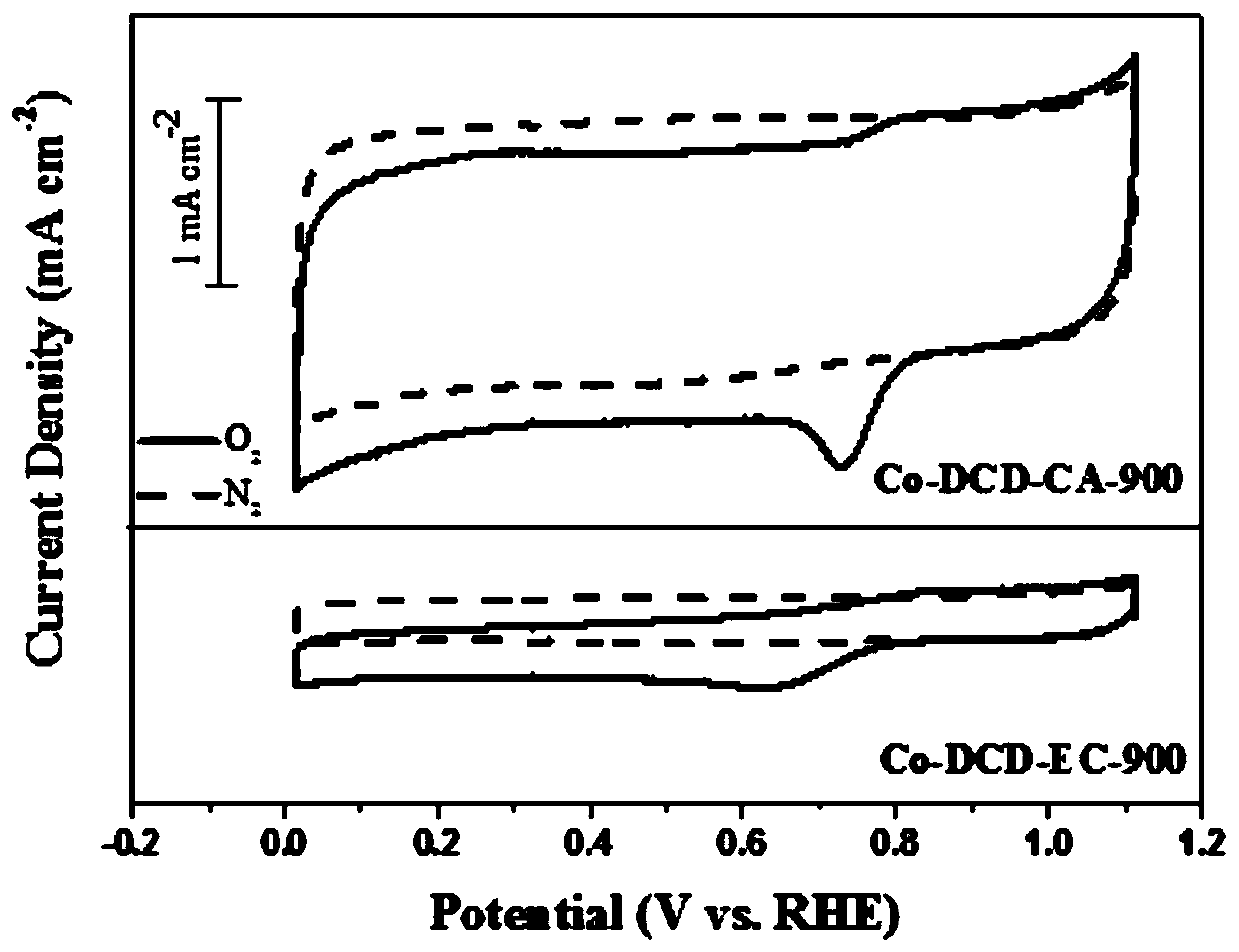

[0049] 5. Put the solid obtained in step 4 into a tube furnace, and burn it at 900°C for 5 hours in a high-purity nitrogen atmosphere to obtain a black powder sample, which is a composite material of nitrogen-doped porous carbon-coated co...

Embodiment 2

[0055] The preparation steps of the composite material of nitrogen-doped porous carbon-coated cobalt nanoparticles in this embodiment are as follows:

[0056] 1. Use an electronic balance to weigh 1.245g of cobalt acetate tetrahydrate and dissolve it in 100mL of deionized water, and stir for 30min to form a transparent solution;

[0057] 2. Weigh 8.4g of dicyandiamine and add it to the solution in the above step 1, heat to 80°C at the same time, and stir until the dicyandiamine is completely dissolved to form a transparent solution;

[0058] 3. Weigh 10.5g of citric acid monohydrate, dissolve in the solution of the above step 2, and continue to stir for 6h;

[0059] 4. Evaporate the solution prepared in the above step 3 to dryness at 120°C;

[0060] 5. Put the solid obtained in step 4 into a tube furnace, and burn it at 900°C for 5 hours in a high-purity nitrogen atmosphere to obtain a black powder sample, which is a composite material of nitrogen-doped porous carbon-coated c...

Embodiment 3

[0063] The preparation steps of the composite material of nitrogen-doped porous carbon-coated cobalt nanoparticles in this embodiment are as follows:

[0064] 1. Use an electronic balance to weigh 1.245g of cobalt acetate tetrahydrate and dissolve it in 100mL of deionized water, and stir for 30min to form a transparent solution;

[0065] 2. Weigh 4.2g of dicyandiamide and add it to the solution in the above step 1, heat to 80°C at the same time, and stir until the dicyandiamine is completely dissolved to form a transparent solution;

[0066] 3. Weigh 10.5g of citric acid monohydrate, dissolve in the solution of the above step 2, and continue to stir for 6h;

[0067] 4. Evaporate the solution prepared in the above step 3 to dryness at 120°C;

[0068] 5. Put the solid obtained in step 4 into a tube furnace, and burn it at 800° C. for 5 hours under a high-purity nitrogen atmosphere to obtain a black powder sample, which is a composite material of nitrogen-doped porous carbon-coa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com