Transverse flux permanent magnet motor of axial magnetic field flux switching type

A technology of magnetic flux switching and transverse magnetic flux, applied in the direction of magnetic circuit shape/style/structure, magnetic circuit, electric components, etc., can solve the problems of excessive axial length, difficult power, complex structure and process, etc. The effect of volume and complexity, reducing maintenance difficulty, and improving fault tolerance performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] In the transverse flux permanent magnet motor of the axial magnetic flux switching type in this embodiment, each single-phase motor module is a double-stator single-rotor structure (see Figure 7 and Figure 8 ), that is, a single-phase motor module includes a rotor and two stators,

[0059] The motor adopts a double-stator single-rotor structure, and the stator includes two parts: a special-shaped stator core and a special-shaped permanent magnet (in this embodiment, the stator core and the permanent magnet are U-shaped stator cores and U-shaped permanent magnets), and the special-shaped stator core and special-shaped permanent magnets Alternately arranged along the circumferential direction to form a flux-switching annular structure stator, there is a stator ring groove on the stator, the direction of the stator ring groove is parallel to the rotating shaft, and a ring winding is arranged in the groove. The number of stator cores is M, the number of special-shaped pe...

Embodiment 2

[0064] The axial magnetic flux switching type transverse flux motor in this embodiment has a high power density, high efficiency, thin structure and simple structure, including a rotor, a special-shaped stator core, a special-shaped permanent magnet, and an armature winding.

[0065] The motor adopts a double-rotor single-stator structure (see Figure 10 ), the stator consists of two inner and outer flux switching stator rings (see Figure 11 ) (the relative positions of the inner and outer circles are as shown in the figure), and each circle is composed of special-shaped permanent magnets and special-shaped stator cores arranged alternately along the circumference to form a ring shape (the stator core and permanent magnets in this embodiment are fan-shaped cylindrical stator cores and fan-shaped cylindrical permanent magnets. magnet (see Figure 19 and Figure 20 )). There is a one-to-one correspondence between the permanent magnets of the inner and outer rings and the pos...

Embodiment 3

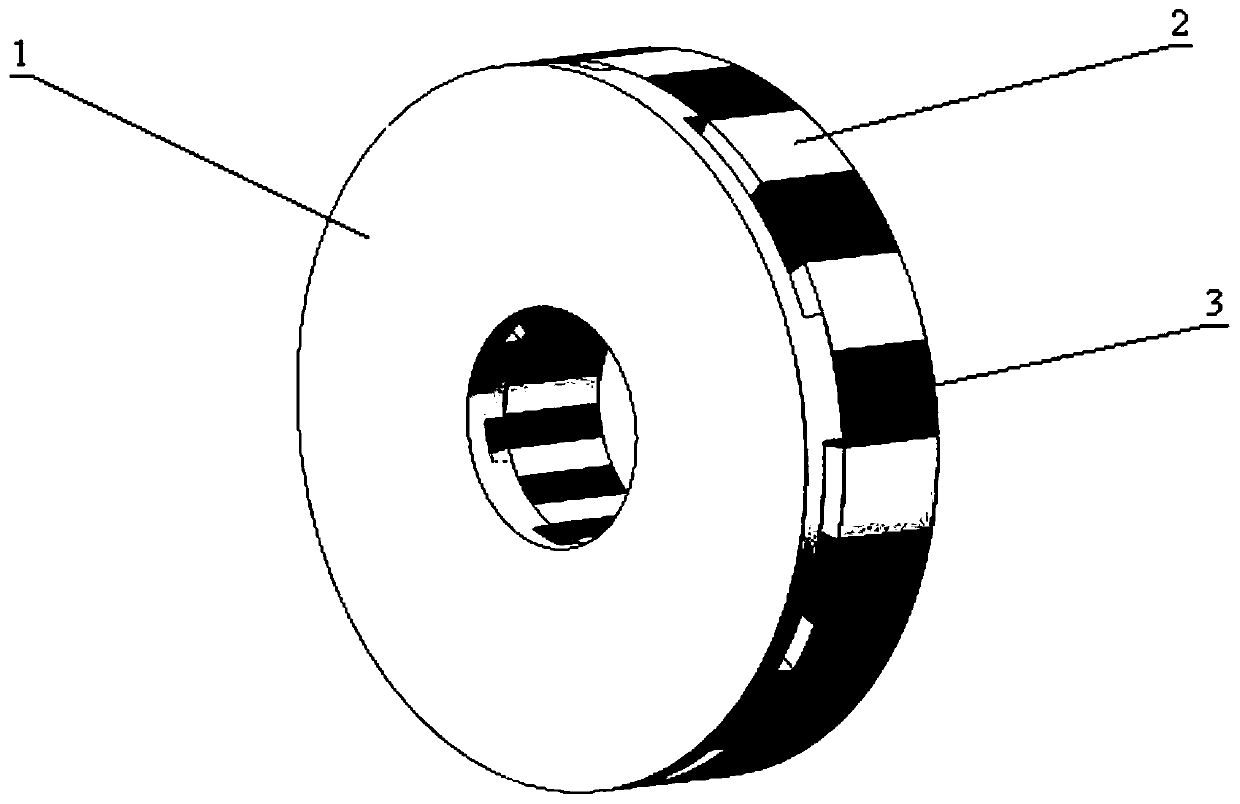

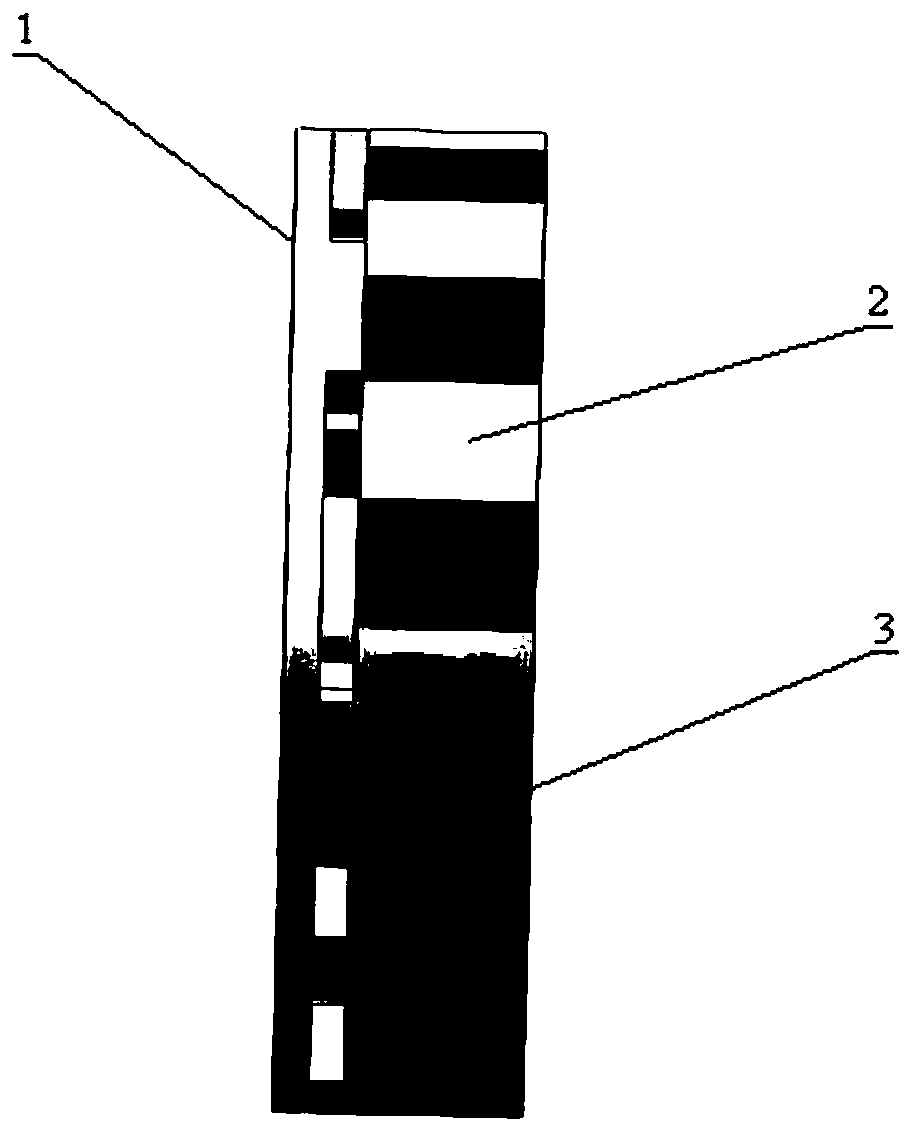

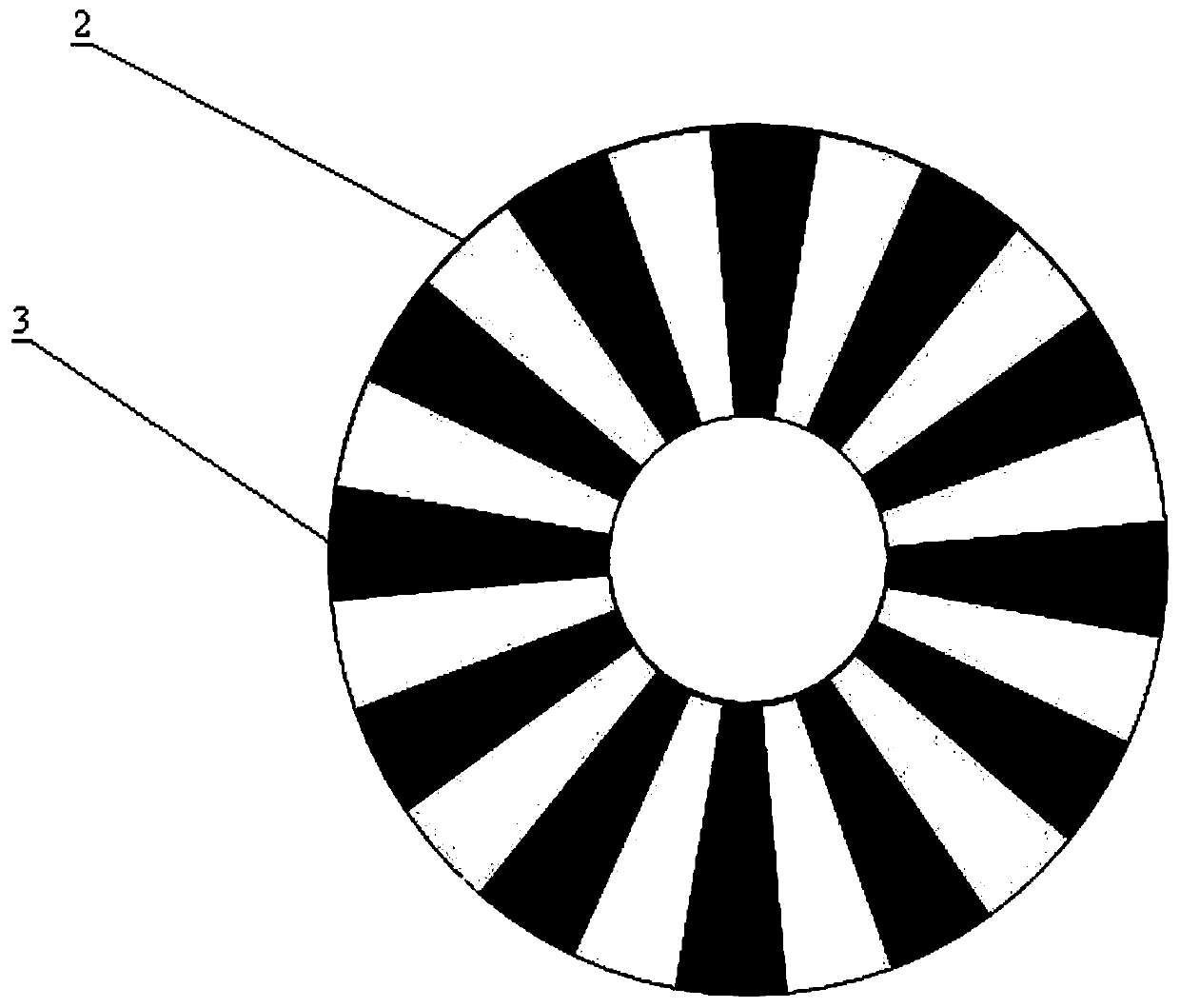

[0071] In this embodiment, the axial magnetic flux switching type transverse flux permanent magnet motor is composed of a plurality of single-phase motor modules, and adjacent single-phase motor modules are offset by a specific angle in the radial direction. Each single-phase motor module has a single-stator and single-rotor structure (see figure 1 ). It includes rotor 1, M special-shaped stator cores 2, M special-shaped permanent magnets 3 and ring-shaped armature windings 6; M special-shaped stator cores and M special-shaped permanent magnets are arranged alternately along the circumferential direction to form a complete ring shape. There are stator ring grooves, the number of special-shaped stator cores and special-shaped permanent magnets is equal, and the number is an even number (see Figure 4 ), the specific shape of the special-shaped stator core and the special-shaped permanent magnet is a U-shaped structure in the present embodiment (see Figure 17 , Figure 18), ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com