Preparation method of porous indium oxide/indium sulfide heterogeneous junction material

A technology of indium oxide and indium sulfide, which is applied in the field of preparation of porous indium oxide/indium sulfide heterojunction materials, can solve problems such as restricting large-scale application and complex de-templated process experimental conditions, and achieves a simple, easy-to-operate and good preparation method. The effect of photocatalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The invention provides a method for preparing a porous indium oxide / indium sulfide heterojunction material, comprising the following steps:

[0034] (1) mixing polyvinylpyrrolidone, indium nitrate and water to obtain a precursor solution;

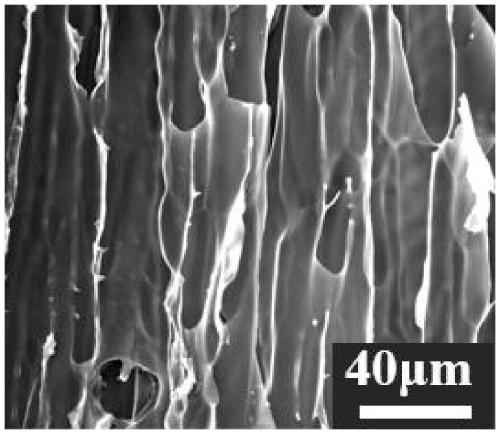

[0035] (2) The precursor solution obtained in the step (1) is subjected to freezing treatment and deicing treatment in sequence to obtain a polyvinylpyrrolidone / indium nitrate hybrid material with a porous structure;

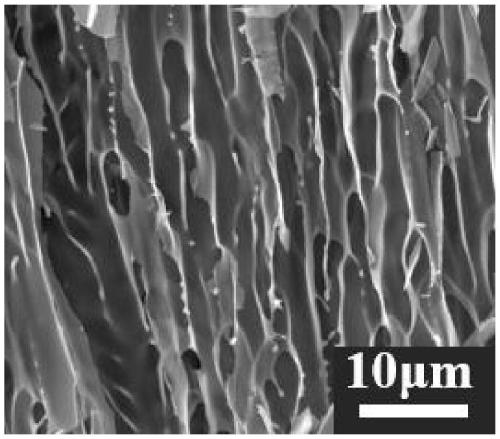

[0036] (3) Calcining the porous polyvinylpyrrolidone / indium nitrate hybrid material obtained in the step (2) to obtain porous indium oxide;

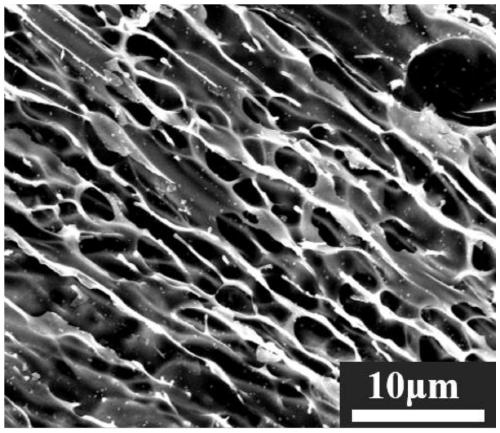

[0037] (4) After the porous indium oxide obtained in the step (3) is mixed with L-cysteine and water, a hydrothermal reaction is performed to obtain a porous indium oxide / indium sulfide heterojunction material.

[0038] In the present invention, all raw materials are commercially available unless otherwise specified.

[0039] The invention mixes polyvinylpyrrolidone, indium n...

Embodiment 1

[0057] (1) Add 2g In(NO 3 ) 3 Dissolve in 100 mL of deionized water, then add 5 g of polyvinylpyrrolidone (abbreviated as PVP), and stir magnetically at a speed of 600 r / min for 8 h to obtain a precursor solution.

[0058] (2) Inject the precursor solution into a 5mL centrifuge tube, immerse it vertically in -196°C liquid nitrogen at a certain speed, keep it for 15min, and then transfer it to a vacuum freeze dryer. Keeping it under the condition for 48h, the porous structure PVP / In(NO 3 ) 3 hybrid materials.

[0059] (3) PVP / In(NO 3 ) 3 The hybrid material was placed in a muffle furnace, and the heating rate during the whole process was 1°C / min, from room temperature to 300°C, kept in the air for 1h, then raised from 300°C to 550°C, and kept for 2h, and then naturally down to room temperature, the porous In 2 o 3 Material.

[0060] (4) Dissolve 0.0625 mmol of L-cysteine in 20 mL of deionized water, and then add 20 mg of porous In 2 o 3 , kept for 1 h, then the mix...

Embodiment 2

[0063] (1) Add 2g In(NO 3 ) 3 and 10 g of PVP were dissolved in 100 mL of deionized water, and magnetically stirred at a speed of 700 r / min for 12 h to obtain a precursor solution.

[0064] (2) Inject the precursor solution into a 5mL centrifuge tube, immerse it vertically in liquid nitrogen at -196°C at a certain speed, keep it for 10min, and then transfer it to a vacuum freeze dryer. Keeping it under the condition for 40h, the porous structure PVP / In(NO 3 ) 3 hybrid materials.

[0065] (3) PVP / In(NO 3 ) 3 The hybrid material was placed in a muffle furnace, and the heating rate during the whole process was 1°C / min, from room temperature to 300°C, kept in the air for 1h, then raised from 300°C to 550°C, and kept for 2h, and then naturally down to room temperature, the porous In 2 o 3 Material.

[0066] (4) Dissolve 0.125mmol L-cysteine in 20mL deionized water, then add 20mg porous In 2 o 3 , kept for 1.5h, then the mixed solution was transferred to an autoclave, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com