A kind of preparation method of vegetable oil/wax composite emulsion wood waterproofing agent

A composite emulsion and waterproofing agent technology, which is applied in the direction of wood impregnation, wood treatment, impregnated wood, etc., can solve the problems of reducing wood hygroscopicity and lack, and achieve the effects of reducing hygroscopicity, improving hydrophobicity, and improving dimensional stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

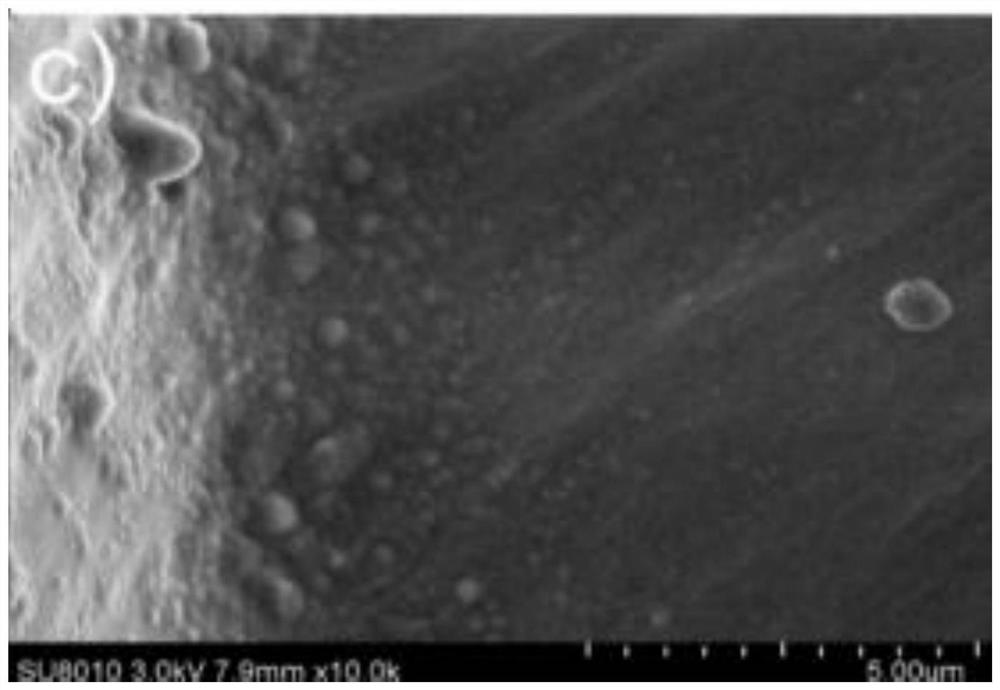

Image

Examples

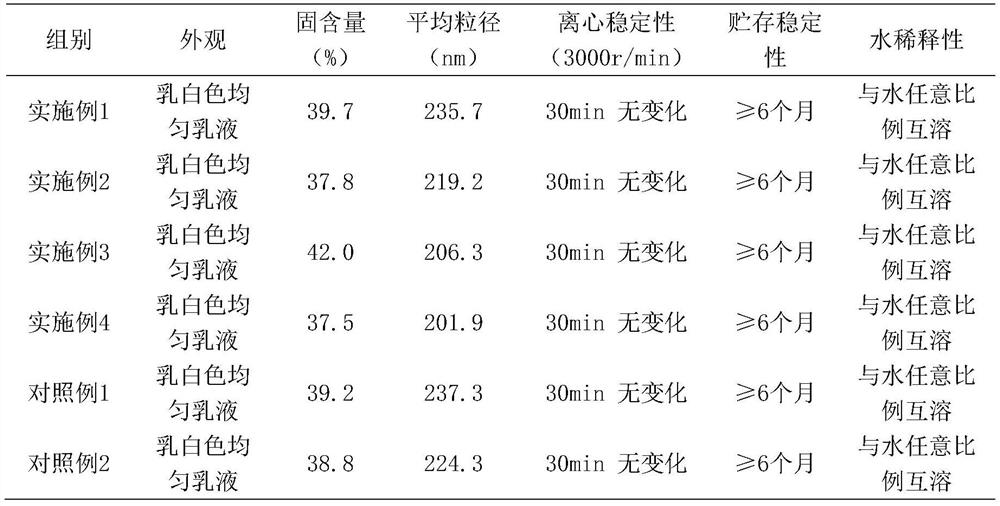

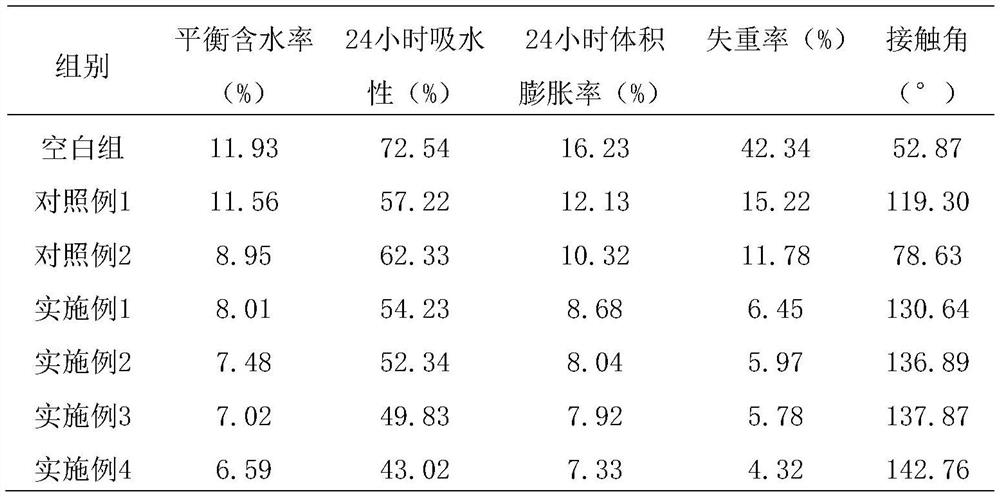

Embodiment 1

[0023] Place 150g of fatty alcohol polyoxyethylene ether, 10g of disodium lauryl sulfosuccinate monoester and 250g of montan wax at 80°C, and stir with a stirrer at a speed of 1000rpm for 10min for later use; at the same time, put 20g of coconut Oil fatty acid acyldiethanolamine, 40g ethanol and 250g epoxidized peanut oil were also placed under the condition of 80°C, and stirred at a speed of 1000rpm for 10min with a stirrer for later use. Maintain the temperature condition of 80 ℃, slowly add the mixture of coconut oil fatty acyldiethanolamine, ethanol and epoxidized peanut oil to the mixture of fatty alcohol polyoxyethylene ether, lauryl sulfosuccinic acid monoester disodium and Montan wax, and Stir at a speed of 4000 rpm, then slowly add 1000 g of water at a temperature of 80° C., and stir at a speed of 7000 rpm for 10 min to complete the preparation of the primary emulsion. The primary emulsion is subjected to high-pressure homogenization through a high-pressure homogenize...

Embodiment 2

[0025] Put 125g of castor oil polyoxyethylene ether, 12.5g of disodium fatty alcohol polyoxyethylene ether sulfosuccinate monoester and 250g of beeswax under the condition of 85°C, and use a stirrer to stir at a speed of 1500rpm for 10min for later use; meanwhile, 25g of coconut oil fatty acid acyldiethanolamine phosphate, 50g of n-propanol and 250g of epoxidized rapeseed oil were also placed under the condition of 85°C, and stirred at a speed of 1500rpm for 10min with a stirrer for later use. Keeping the temperature at 85°C, slowly add coconut oil fatty acid acyldiethanolamine phosphate, n-propanol and epoxy The mixture of rapeseed oil was stirred at a speed of 5000rpm, and then 1000g of water at a temperature of 85°C was slowly added, and stirred at a speed of 8000rpm for 15min to complete the preparation of the primary emulsion. Pass the primary emulsion through a high-pressure homogenizer for high-pressure homogenization, with a homogenization pressure of 50 MPa, and homog...

Embodiment 3

[0027]Place 155g of alkylphenol polyoxyethylene ether, 9g of cocoic acid monoethanolamide sulfosuccinic monoester disodium and 250g of solid paraffin under the condition of 90°C, use a stirrer to stir at a speed of 2000rpm for 10min and set aside; at the same time , 25g of monolauryl phosphate, 50g of isopropanol and 250g of epoxidized soybean oil were also placed under the condition of 90°C, and stirred at a speed of 1500rpm for 10min with a stirrer for later use. Keeping the temperature at 90°C, slowly add monolauryl phosphate, isopropanol and epoxy to the mixture of alkylphenol polyoxyethylene ether, cocoic acid monoethanolamide sulfosuccinate monosodium disodium and solid paraffin. The mixture of soybean oil was stirred at a speed of 6000rpm, and then 1000g of water at a temperature of 90°C was slowly added, and stirred at a speed of 9000rpm for 220min, and the primary emulsion was prepared. Pass the primary emulsion through a high-pressure homogenizer for high-pressure ho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com