Device for dynamically monitoring ultra-precise machining toughness and brittleness removal of ceramic material

A technology of ultra-precision machining and ceramic materials, applied in stone processing tools, stone processing equipment, work accessories, etc., can solve the problems of wasting materials, consuming energy, and prolonging the test period.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with accompanying drawing and specific embodiment its technical scheme is further elaborated

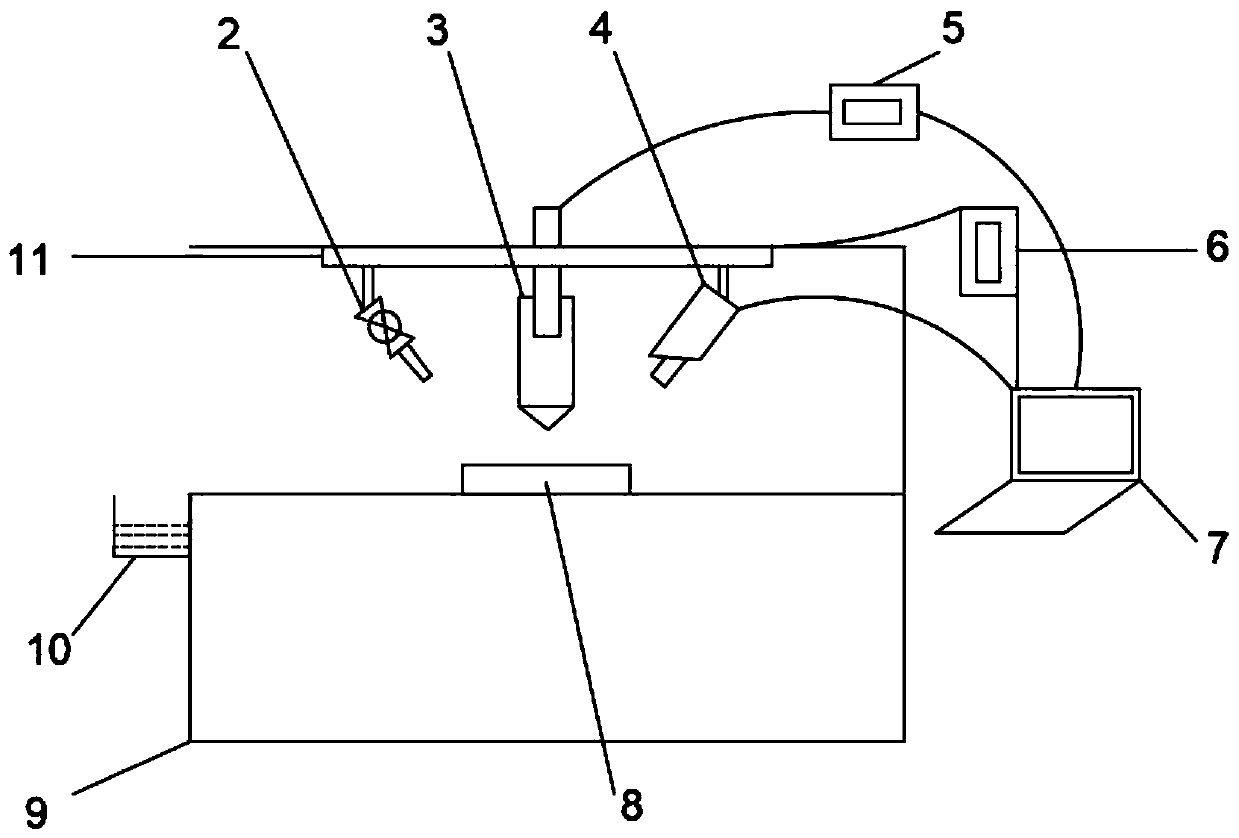

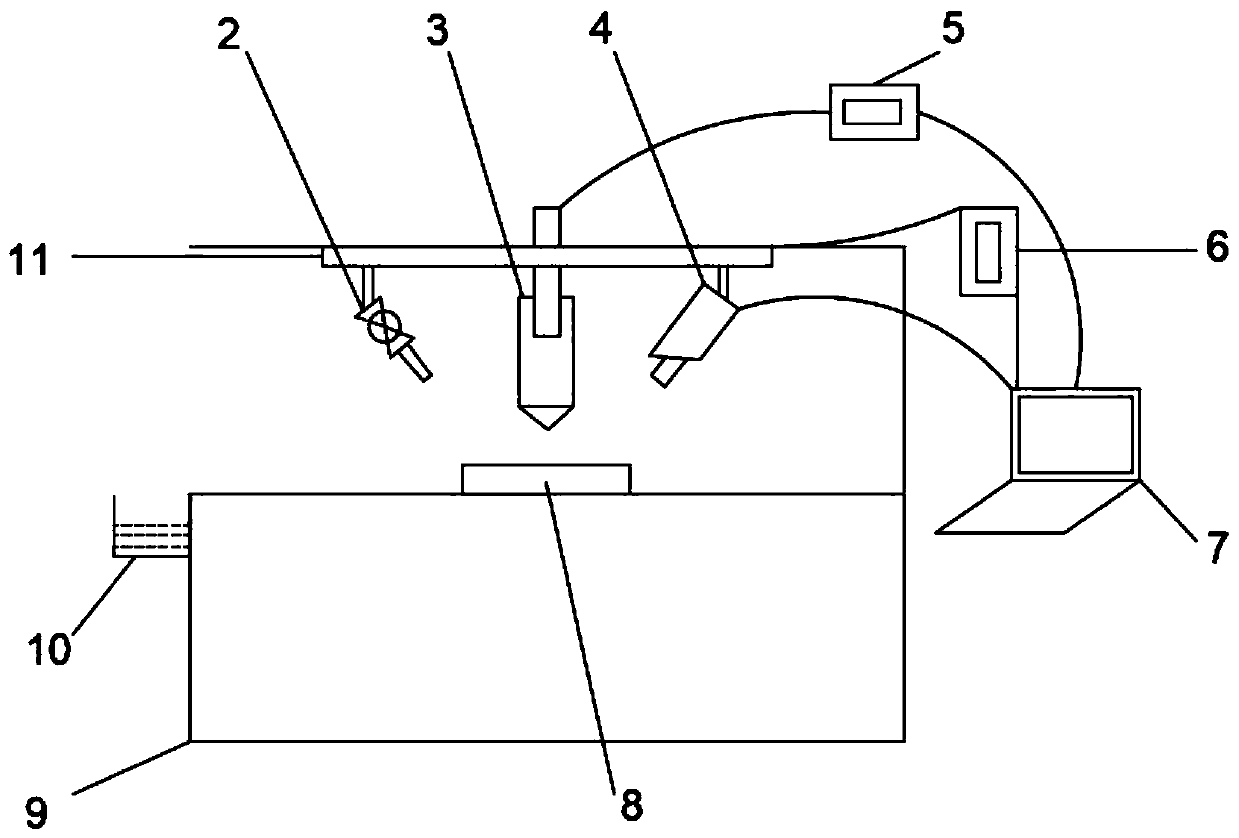

[0025] Such as figure 1 Shown is a structural schematic diagram of a ceramic material ultra-precision machining, data acquisition, and feedback integrated prototype of the present invention. The integrated prototype includes an ultra-precision machining system, a cooling system, a data acquisition system, a logic judgment system, and processing speed and depth. Control System.

[0026] The ultra-precision machining system is used for ultra-precision machining of ceramic materials, and is mainly composed of lathes, cutting tools and ceramic workpieces.

[0027] The cooling system is composed of cooling liquid, cooling liquid sprayer and cooling liquid recovery tank, and is used to eliminate the influence of processing heat on the workpiece.

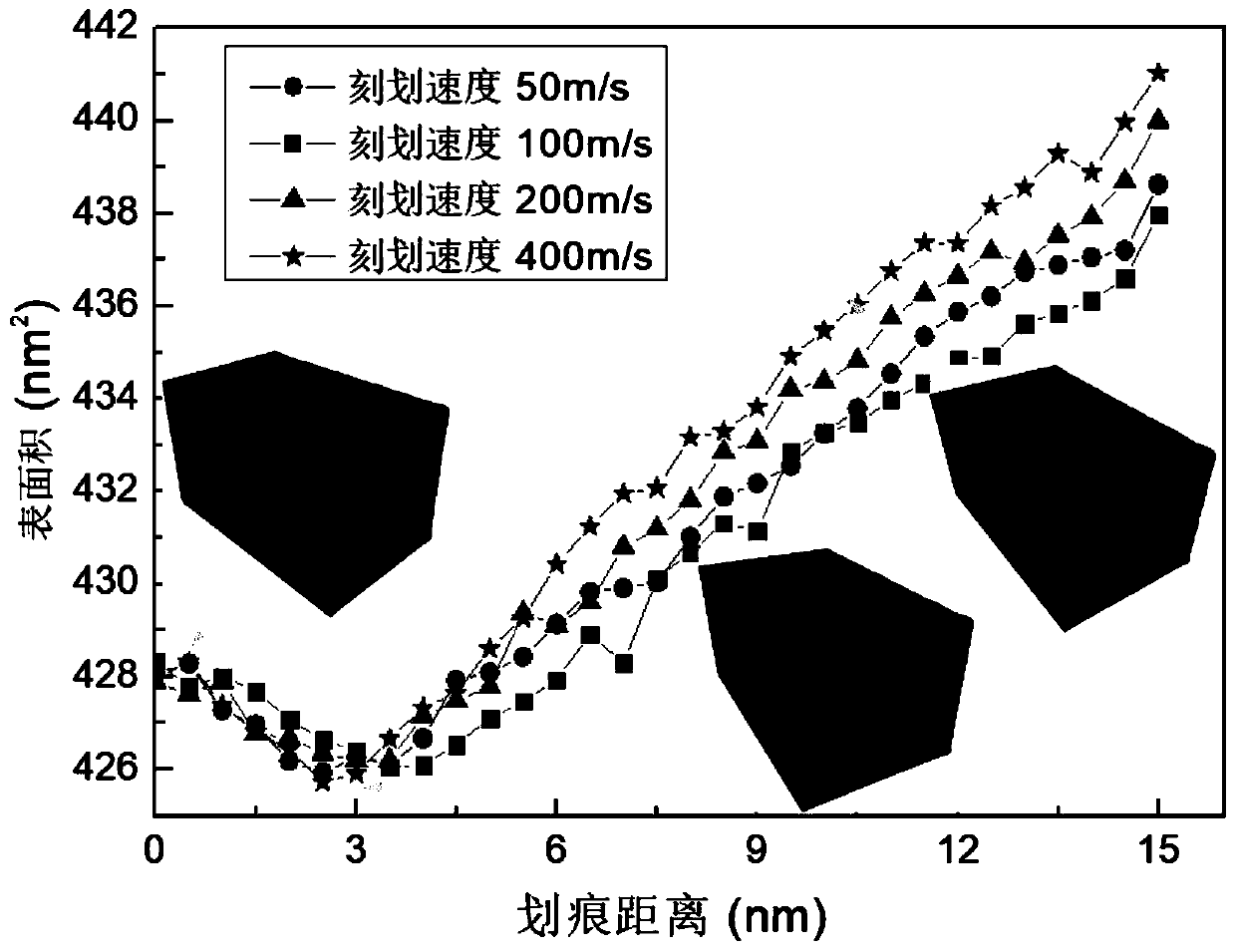

[0028] The data acquisition system is used to collect and record data on the surface area of the ultra-precisio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com