Novel laser-structuring diamond abrasive particle polishing pad and abrasive particle structuring method thereof

A laser structuring and diamond technology, applied in the direction of abrasives, metal processing equipment, manufacturing tools, etc., can solve the problems of multi-directional movement that cannot be used for polishing, achieve high hardness of abrasive grains, improve surface integrity, and improve surface processing quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

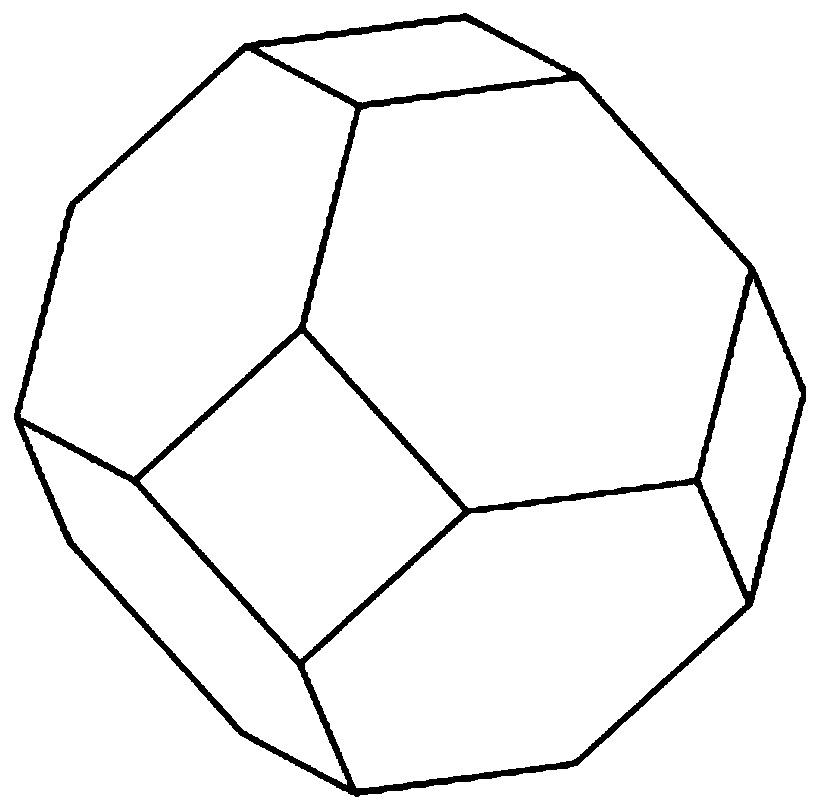

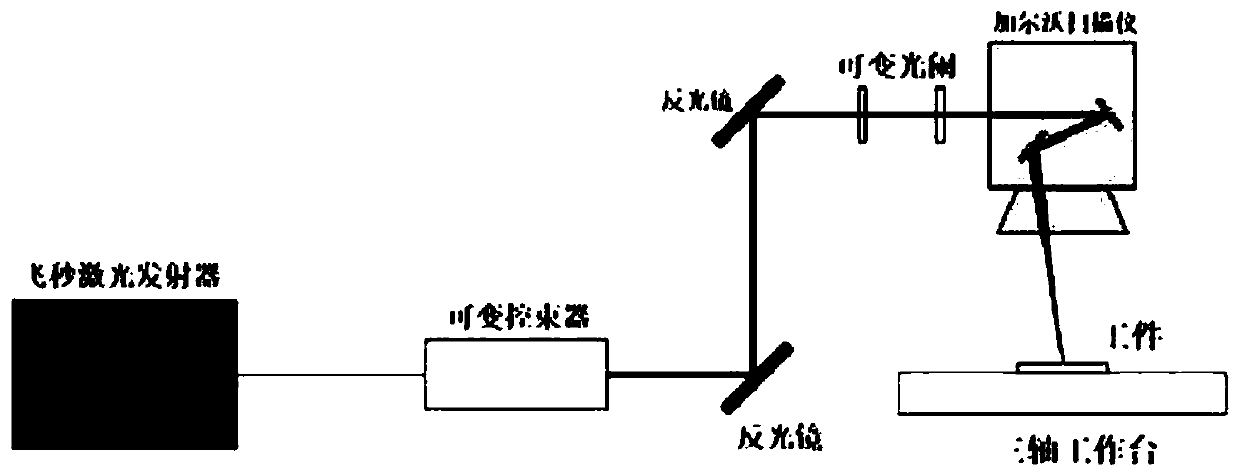

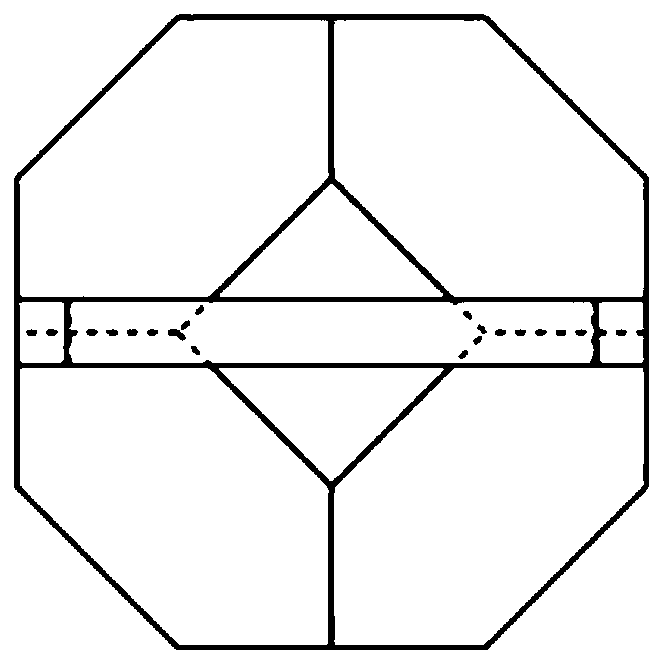

[0026] Embodiment 1: as Figure 1-Figure 7 As shown, a new type of laser structured diamond abrasive polishing pad includes diamond abrasive grains 1 and polishing pad 2. Diamond abrasive grains 1 are laid on the polishing pad 2. There are many micro-edges 3 with different heights on the surface of diamond abrasive grains 1. And abrasive groove 4.

[0027] Preferably, the above-mentioned polishing pad 2 is made of a hydrophilic material, and the diamond abrasive grains 1 are thermally fixed on the polishing pad 2 by resin to form a square small protrusion array structure 5 and spacing grooves 6 between the arrays.

[0028] A method for structuring abrasive grains of a novel laser structured diamond abrasive grain polishing pad, the method comprising the following steps:

[0029] (1) Choose truncated octahedral diamond as diamond abrasive grains, the abrasive grain size is 50 μm, the characteristics of the original abrasive grains are as follows figure 1 As shown, the diamond...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com